Method for laboratory verification of dispersibility of soft pvc powder additives based on calcium stearate and soybean oil

A technology of calcium stearate and soybean oil, which is applied in the direction of analyzing materials, instruments, surface/boundary effects, etc., can solve the problem of different plasticization degrees of formula materials, affecting the dispersion performance of powder additives, and incomplete powder plasticization and other issues to achieve the effective effect of the test method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The instruments used in this example include: Plasmec brand turbine mixer (TRL-10 / FV / R); VowerkThermomix TM-31 small mixer; Dr.collin twin-roll mixer, model W 150E*400; Deli NO.8012 cut paper knife.

[0027] The raw materials in this example include: Formosa Plastics PVC powder grade S-70, plasticizer DOTP, soybean oil, calcium stearate (Lianyungang Huamingtai), and powder additive-A, powder additive-B , Powder additive-C, Powder additive-D.

[0028] In the present embodiment, the method for verifying the dispersibility of the soft PVC powder additive comprises the following steps:

[0029] (1) Preparation of premix

[0030] Accurately weigh 2kg of PVC powder S-70 and 800g of liquid plasticizer DOTP respectively. Put it into a high mixer and mix at 600r / min for 10 minutes to prepare premix S-13.

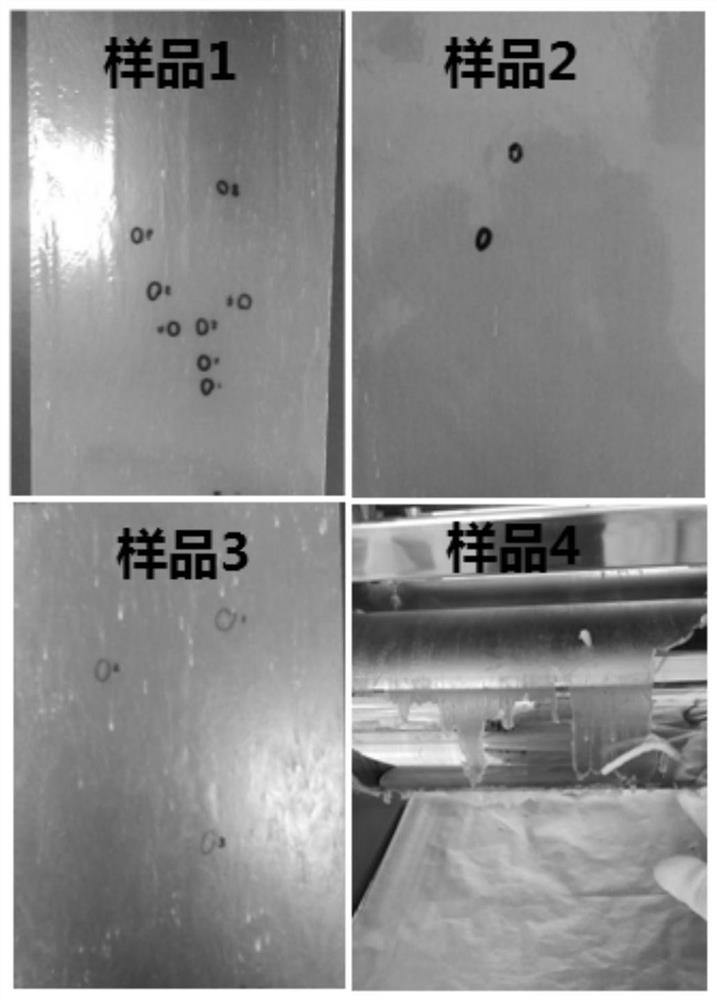

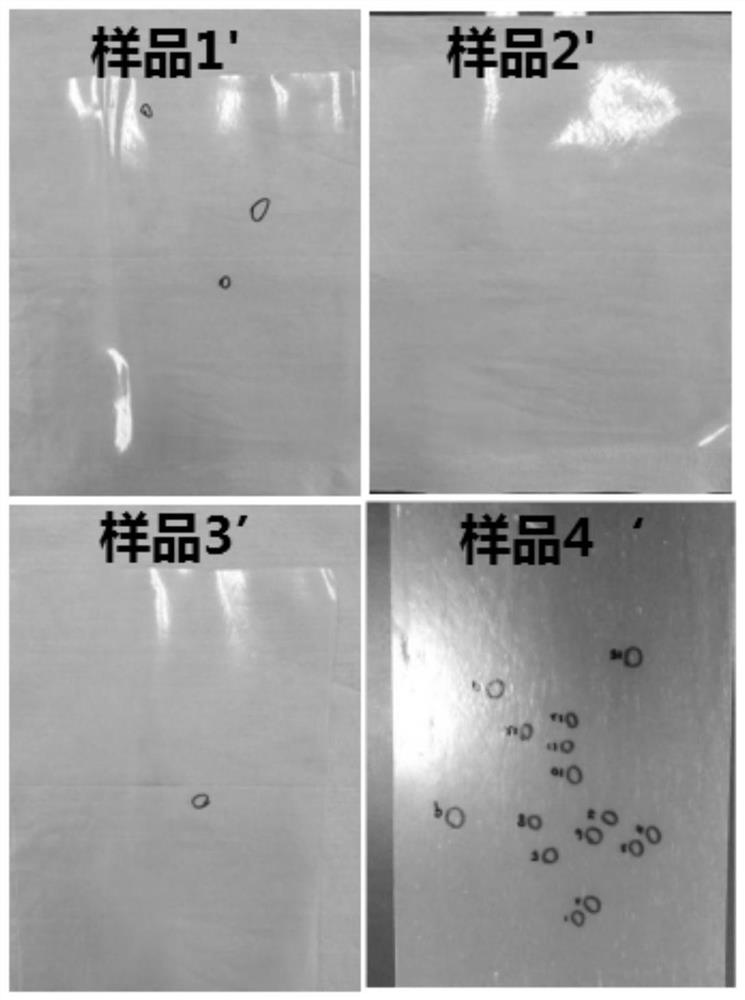

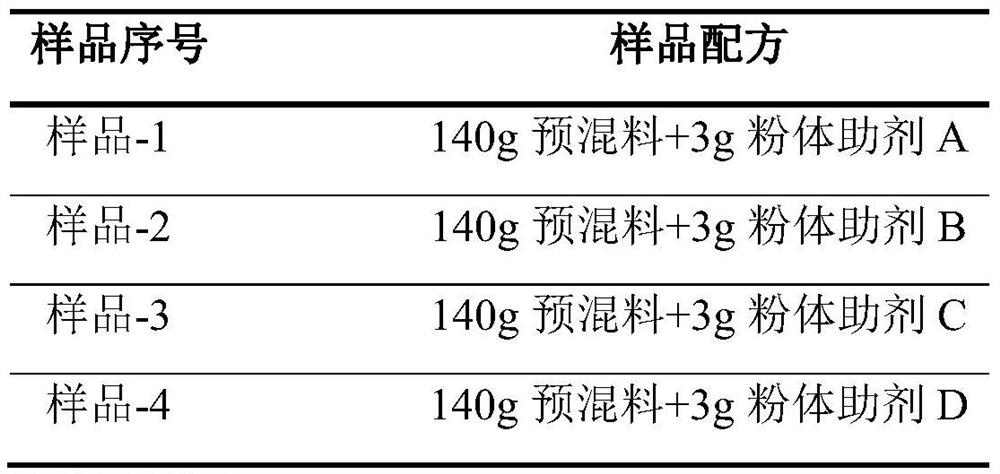

[0031] (2) Prepare powder additives and directly mix samples

[0032] Select powder additive samples A, B, C, D. Weigh 3g of powder additives respectively, put them into...

Embodiment 2

[0058] Feedback on customer application of powder additives in Table 6 Example 2

[0059]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com