Workpiece platform and heating device for reflectivity test of absorbing material

A technology of microwave absorbing material and heating device, which is applied in the direction of material analysis, measuring device and electric heating device using microwave means, which can solve the problems of personnel burns, uneven heating, deformation of the sample to be tested, etc., and reduce conduction and consumption. Speed, improve test accuracy, use safe and reliable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

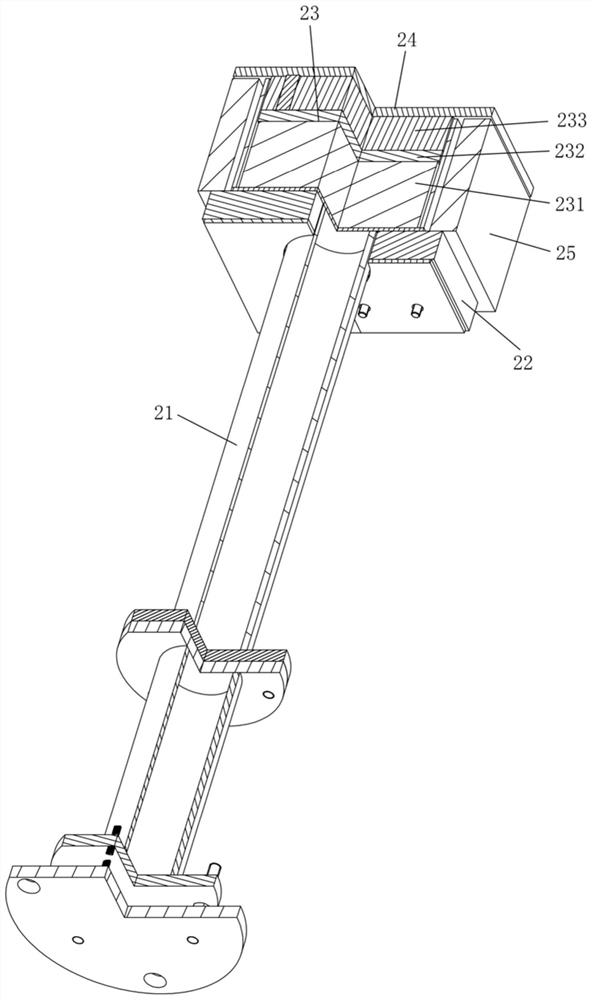

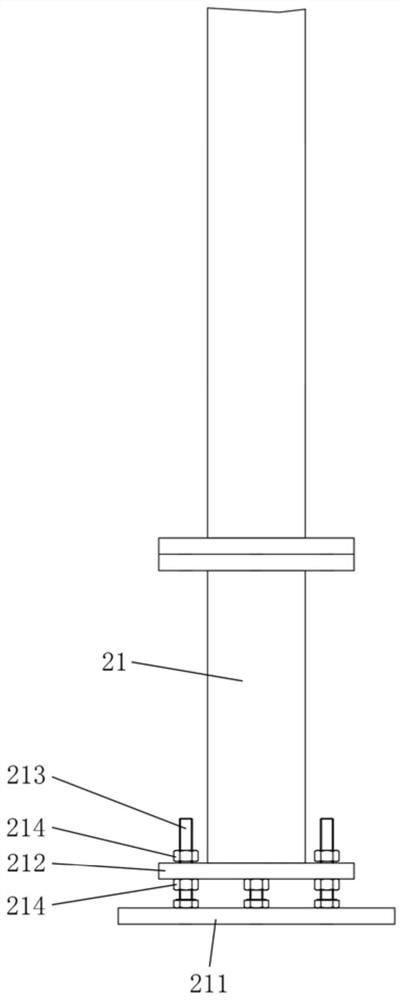

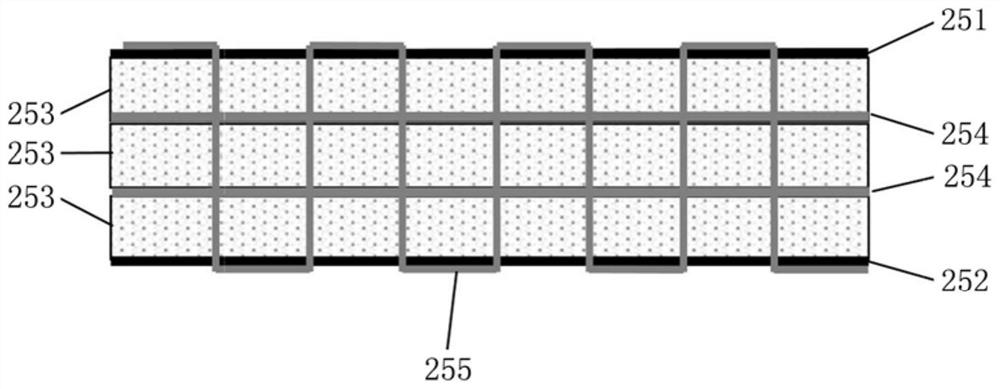

[0030] Such as figure 1 As shown, the workpiece support platform used for the reflectivity test of the absorbing material in this embodiment includes a pillar 21 and a carrying platform connected to the top of the pillar 21. The test backplane 24 of the sample board, the test backplane 24 is used to provide the electromagnetic wave reflection backing, the test backplane 24 is supported on the lower bottom plate 22 through the middle heat insulating element 23, the lower bottom plate 22 is connected on the pillar 21, and the middle heat insulating element 23 There are wave-absorbing shrouds 25 wrapped around it. In the workpiece cap, the surrounding of the bearing platform is covered with a wave-absorbing coaming 25, and the wave-absorbing coaming 25 has heat preservation and wave-absorbing functions, which can reduce the background l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com