An oil-immersed permanent magnet motor

A permanent magnet motor, oil-immersed technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problem of less rotor permanent magnet motors, achieve small torque ripple and vibration noise, reduce viscous loss, The effect of weakening the electromagnetic excitation force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

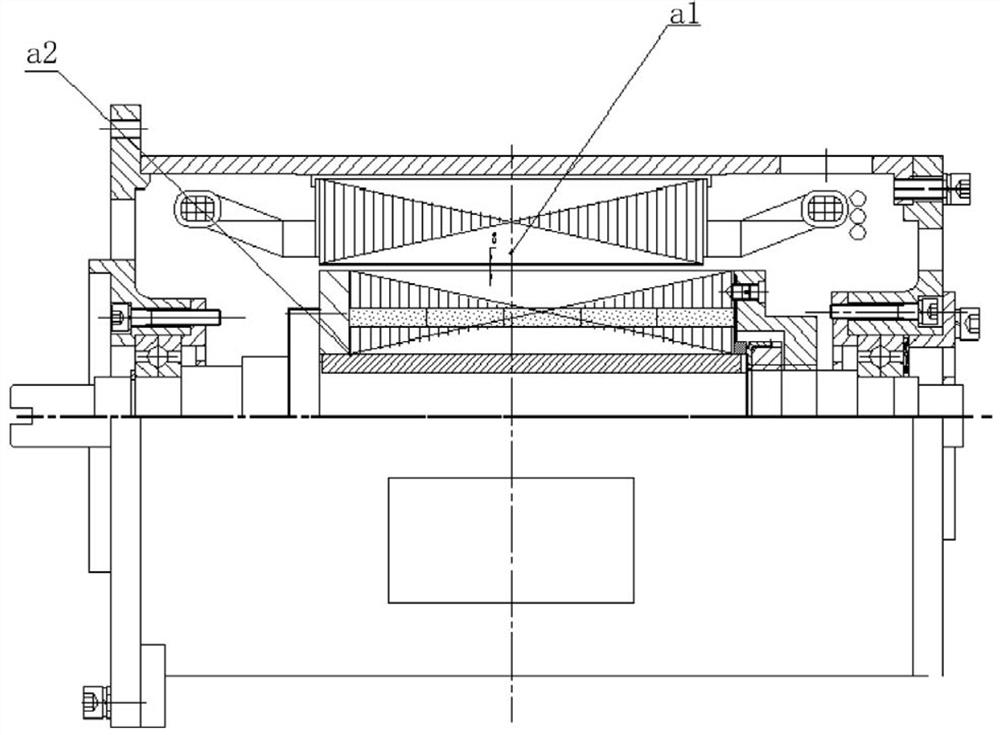

[0023] refer to Figure 1 to Figure 3 As shown, the present invention discloses an oil-immersed permanent magnet motor, which includes a stator a1 and a rotor a2. The stator a1 includes a cylindrical frame with two ends open and a belt winding that is thermally sleeved on the inner wall of the frame. The stator core is provided with 36 stator chute slots on the stator core, and the winding on the stator core adopts double-layer short-pitch winding.

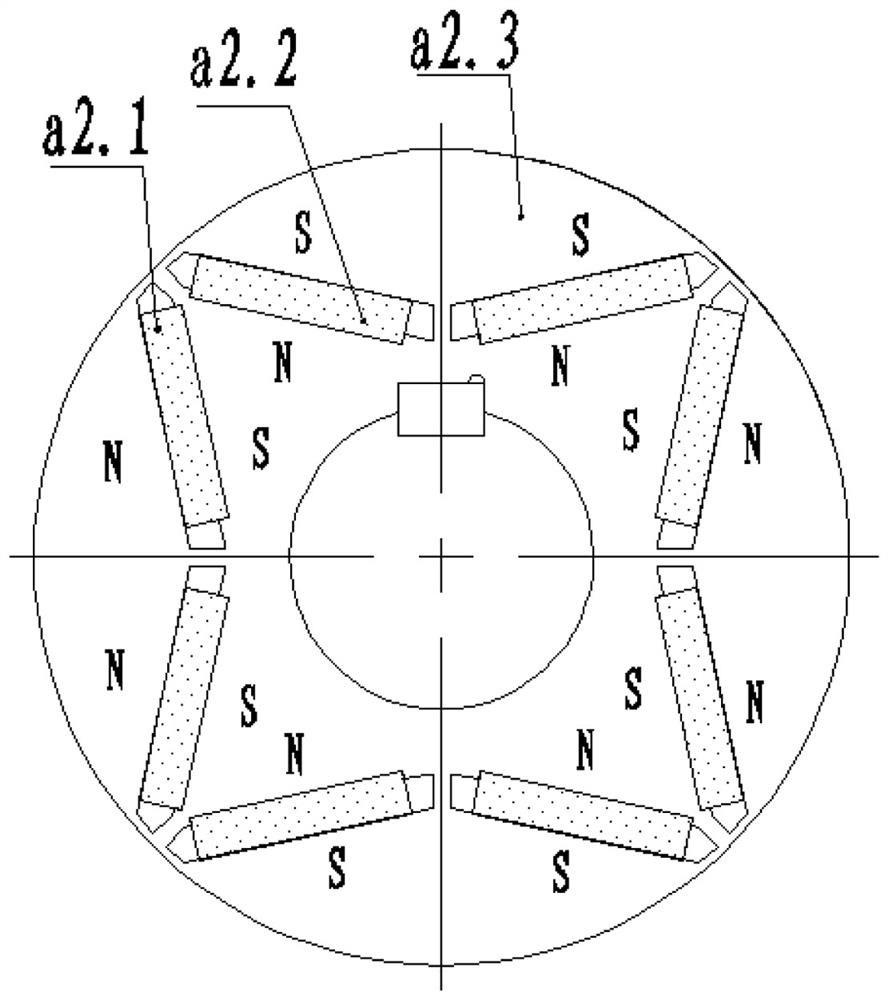

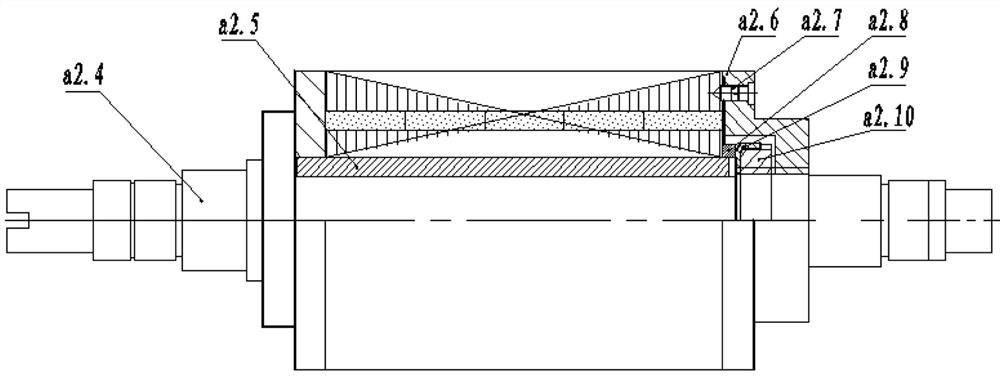

[0024] The rotor a2 includes a rotating shaft a2.4 and a plurality of circular built-in silicon steel sheets a2.3 superimposed and sleeved in the middle of the rotating shaft a2.4. Position groove, the inner circumference of the built-in silicon steel sheet a2.3 is provided with a silicon steel sheet limit groove, and the through hole surrounded by the rotating shaft limit groove and the silicon steel sheet limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com