Glue spraying method based on mask vamp and automatic glue spraying system

A technology of shoe upper and glue spraying, which is applied in the direction of shoe-making machinery, footwear, and bonding shoe parts. , to achieve the effect of outstanding economic effect, saving equipment cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

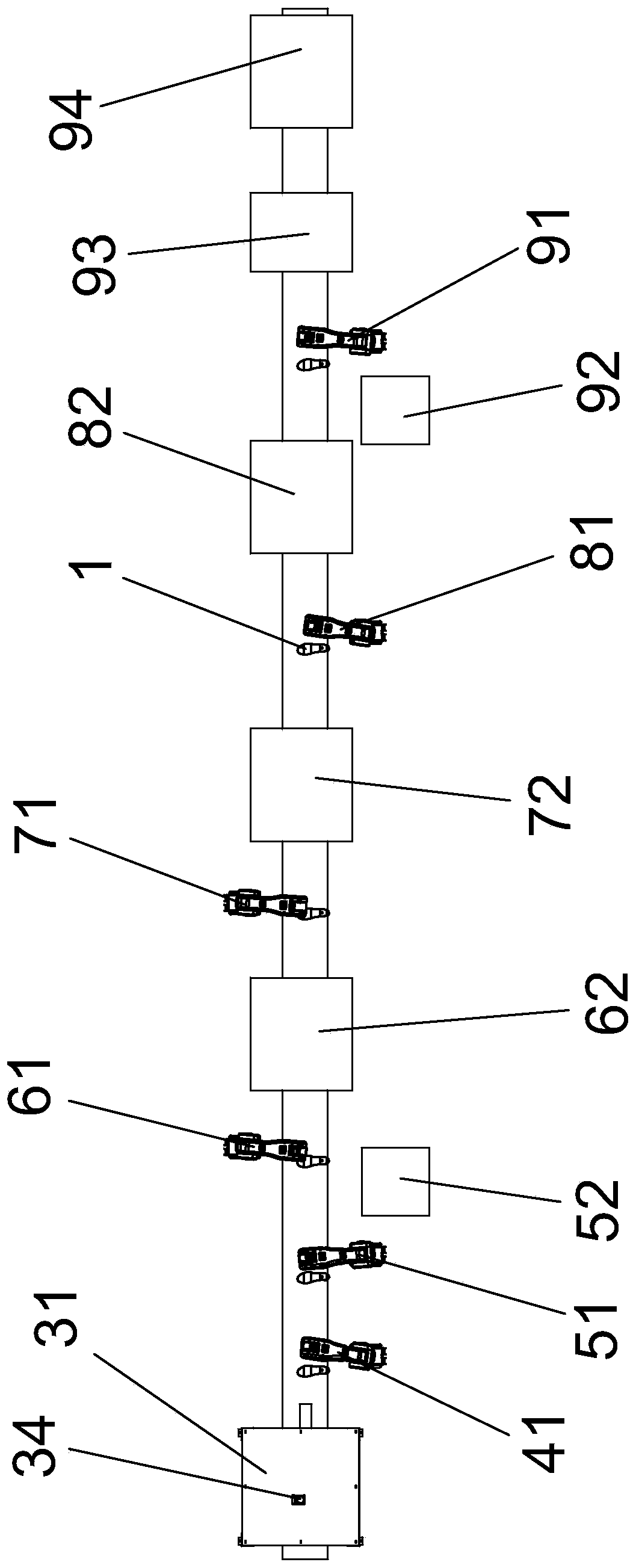

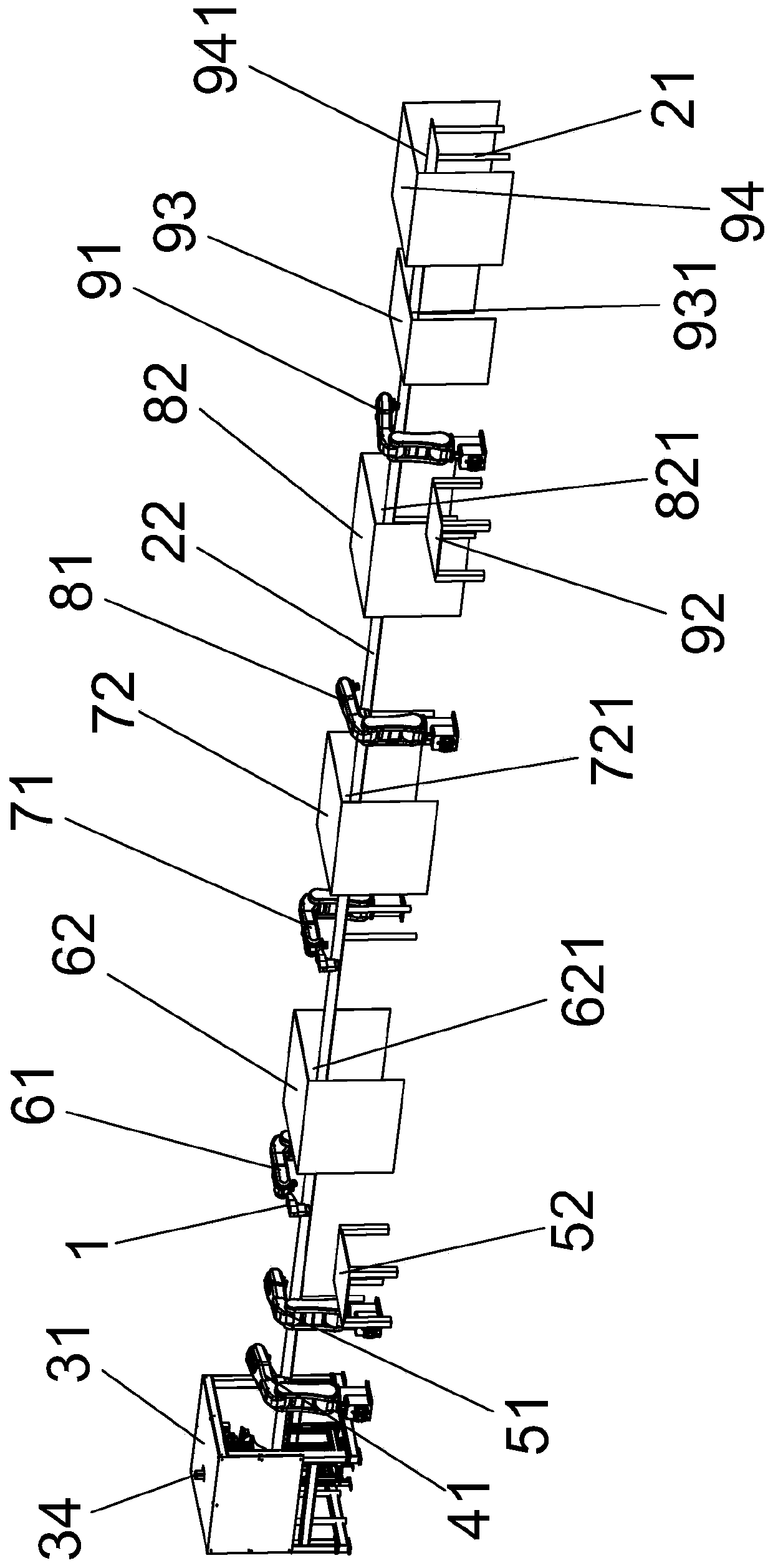

[0042] refer to Figure 1 to Figure 4 , what the embodiment of the present invention discloses is a kind of glue spraying method and automatic glue spraying system based on the mask vamp, the glue spraying steps are as follows:

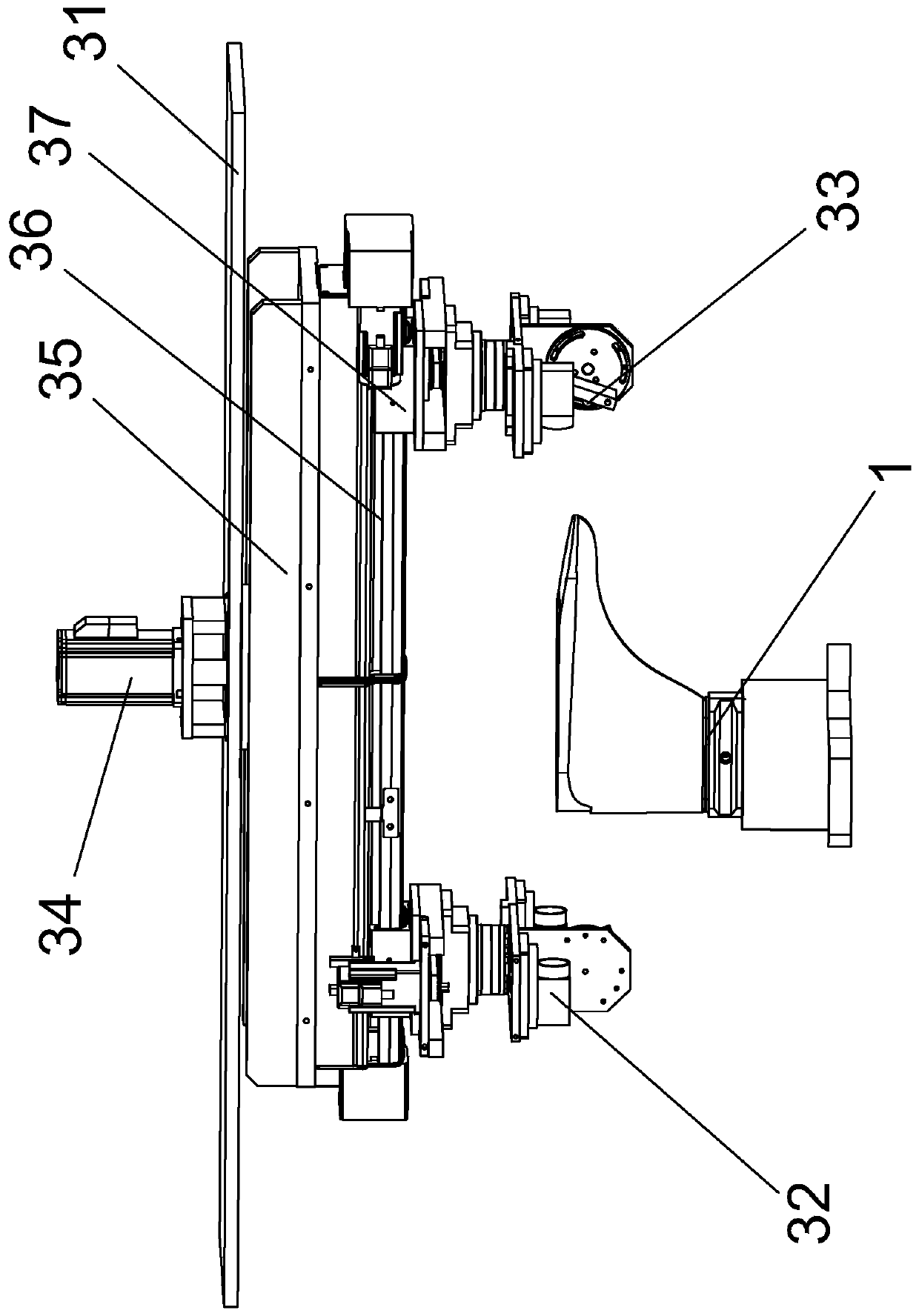

[0043] S1. Loading: The operator first puts the shoe upper on the shoe last 1, then assembles the shoe last 1 on the transmission device through the space in the head of the shoe last 1, and finally puts the corresponding special shoe sole model with the The shoe last 1 is aligned front and rear, left and right, and installed on the upper of the shoe last 1; the transmission device includes a conveyor belt 22, and a driving roller (not shown in the figure) and a number of driven rollers are rotatably arranged on the frame 21 (not shown in the figure), the driving roller and the driven roller are wound with a conveyor belt 2...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap