Production method of sodium bicarbonate injection

A technology of sodium bicarbonate and its production method, which is applied in the direction of pharmaceutical formulations, medical preparations containing active ingredients, and devices that make medicines into special physical or ingestible forms, and can solve the problems of inability to remove impurities and bacteria, use restrictions, Can not remove impurities and microorganisms to achieve the effect of avoiding insufficient dosage, avoiding waste, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

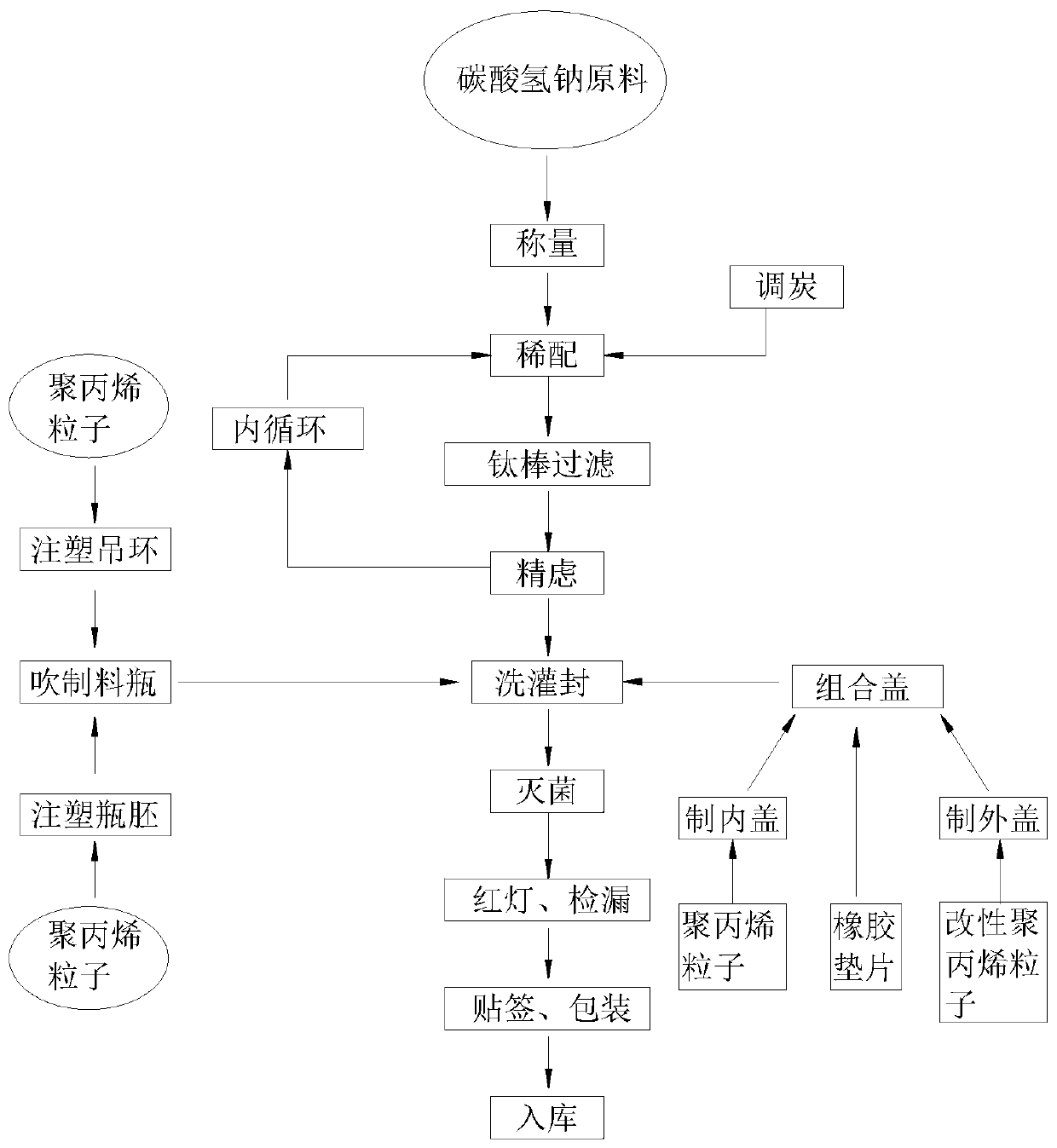

Method used

Image

Examples

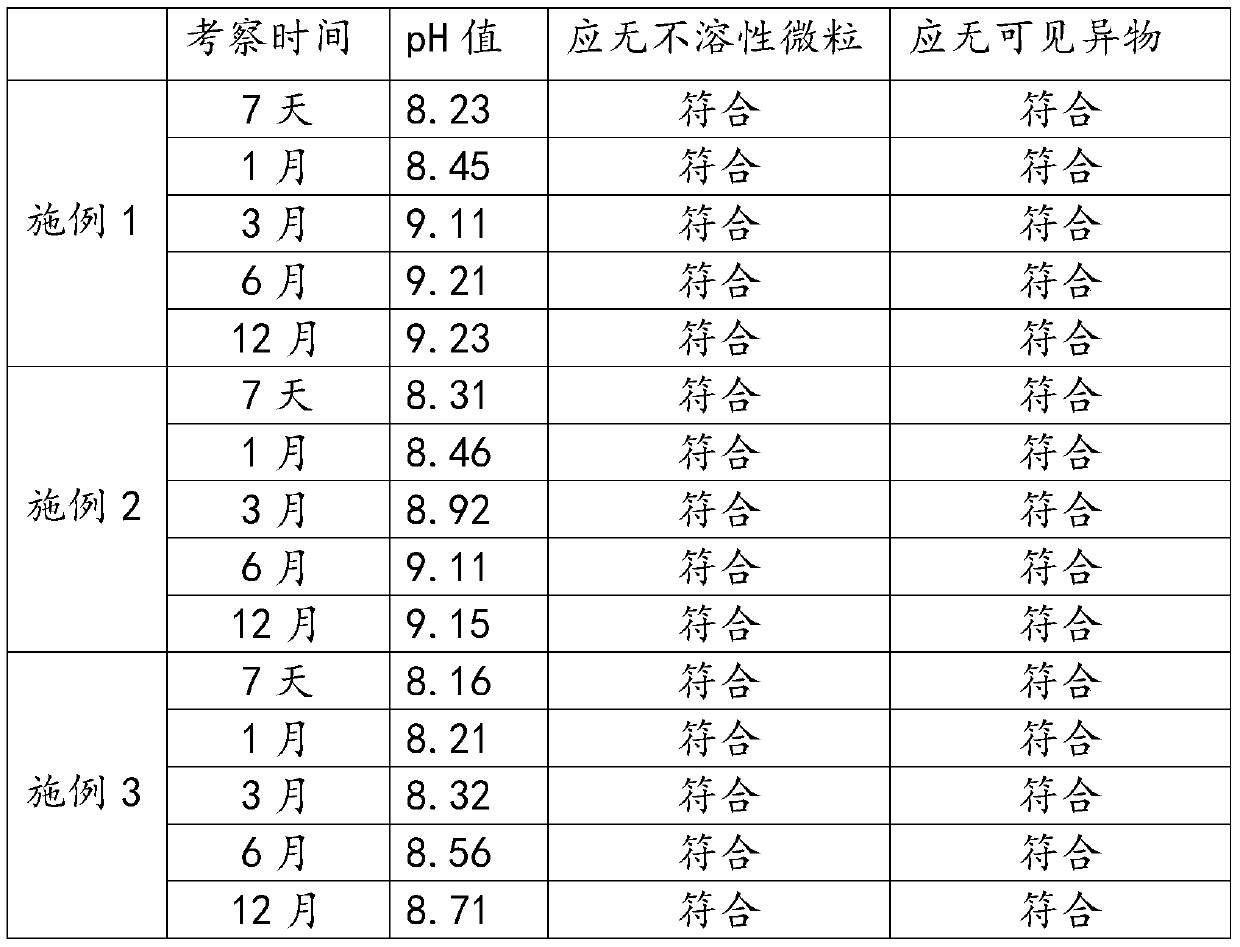

Embodiment 1

[0028] a. Add water for injection into the dilute preparation tank, and cool the water for injection in the dilute preparation tank to 15°C;

[0029] b. Add the soaked activated carbon for needles and sodium bicarbonate into the dilute preparation tank in step a, and feed pure carbon dioxide gas into the dilute distribution tank until the potting is completed;

[0030] c. Add water for injection at 15°C to the dilute mixing tank in step b, and start the dilute mixing tank for stirring;

[0031] d. Pass the solution in the dilute distribution tank into the titanium rod filter for filtration, and the filtration pressure of the titanium rod filter is 0.4MPa;

[0032] e. Pass the solution in the titanium rod filter into a 0.22 μm / 0.45 μm filter for 10 minutes;

[0033] f. Transfer the solution in the 0.22 μm / 0.45 μm filter to the dilution tank of step d for further stirring, repeat step f, step d, and step e three times;

[0034] g. Transport the solution treated in step f to a ...

Embodiment 2

[0038] a. Add water for injection into the dilute preparation tank, and cool the water for injection in the dilute preparation tank to 25°C;

[0039] b. Add the soaked activated carbon for needles and sodium bicarbonate into the dilute preparation tank in step a, and feed pure carbon dioxide gas into the dilute distribution tank until the potting is completed;

[0040] c. Add water for injection at 25°C to the dilute mixing tank in step b, and start the dilute mixing tank for stirring;

[0041] d. Pass the solution in the dilute tank to the titanium rod filter for filtration, and the filtration pressure of the titanium rod filter is 0.1MPa;

[0042] e. Pass the solution in the titanium rod filter into a 0.22 μm / 0.45 μm filter for 10 minutes;

[0043] f. Transfer the solution in the 0.22 μm / 0.45 μm filter to the dilution tank of step d for further stirring, and repeat step f, step d, and step e four times;

[0044]g. Transport the solution treated in step f to a 0.22 μm termi...

Embodiment 3

[0048] a. Add water for injection into the dilute preparation tank, and cool the water for injection in the dilute preparation tank to 30°C;

[0049] b. Add the soaked activated carbon for needles and sodium bicarbonate into the dilute preparation tank in step a, and feed pure carbon dioxide gas into the dilute preparation tank until the potting is completed;

[0050] c. Add 30°C water for injection into the dilute mixing tank in step b, and start the dilute mixing tank for stirring;

[0051] d. Pass the solution in the dilute tank into the titanium rod filter for filtration, and the filtration pressure of the titanium rod filter is 0.25MPa;

[0052] e. Pass the solution in the titanium rod filter into a 0.22 μm / 0.45 μm filter for 10 minutes;

[0053] f. Transfer the solution in the 0.22 μm / 0.45 μm filter to the dilution tank of step d for further stirring, repeat step f, step d, and step e five times;

[0054] g. Transport the solution treated in step f to a 0.22 μm termina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com