Magnetically Retrievable Neodymium Complexes /go/fe 3 o 4 Ternary compound and its preparation method and application

A ternary complex, neodymium complex technology, used in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of photogenerated electrons and holes. Effective separation, difficult catalyst recovery of MOFs, poor catalytic activity, etc., achieve the effects of fast and efficient degradation, high yield and purity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation of neodymium complex 1:

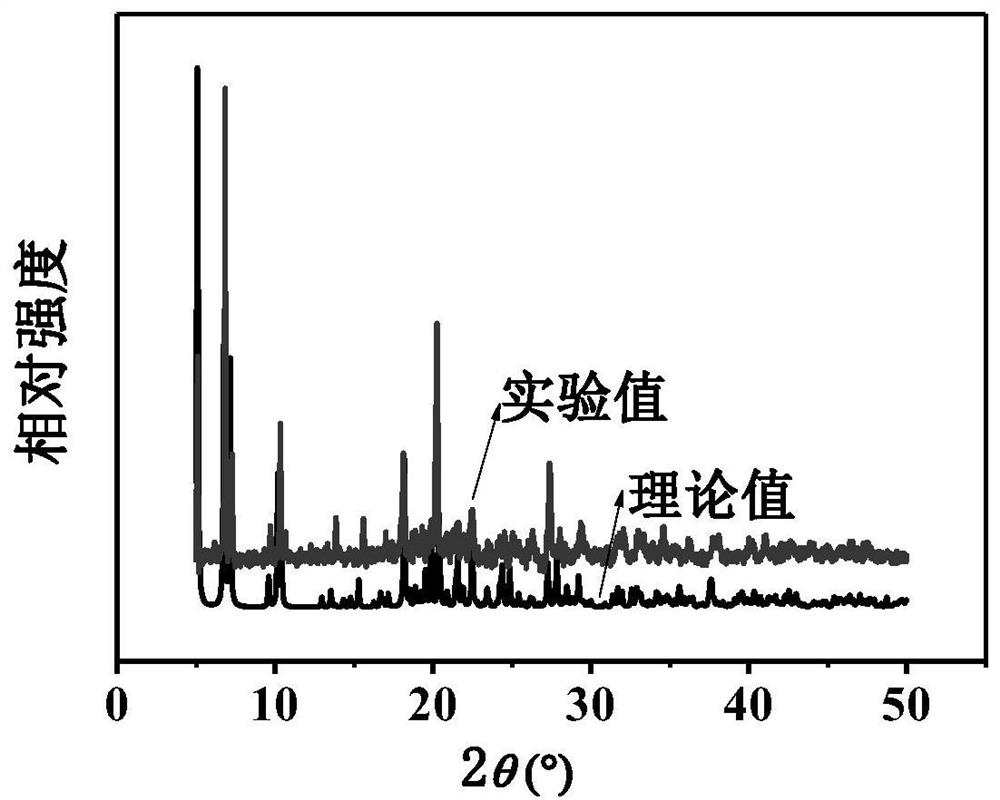

[0041] Weigh NdCl respectively 3 ·6H 2 O (35.3 mg, 0.1 mmol) and H 3 TCPB (48.6mg, 0.1mmol) was placed in a 23mL polytetrafluoroethylene reactor lining, and 2mL distilled water, 3mL DMF and 3mL absolute ethanol were added, stirred at room temperature for 30 minutes, and then sealed in a stainless steel reactor , after 72 hours of constant temperature reaction in a temperature-controllable oven at 120°C, it was naturally cooled to room temperature to obtain a purple block crystal that meets the requirements of the X-Ray test. The yield was about 42% after continuous washing with distilled water and drying.

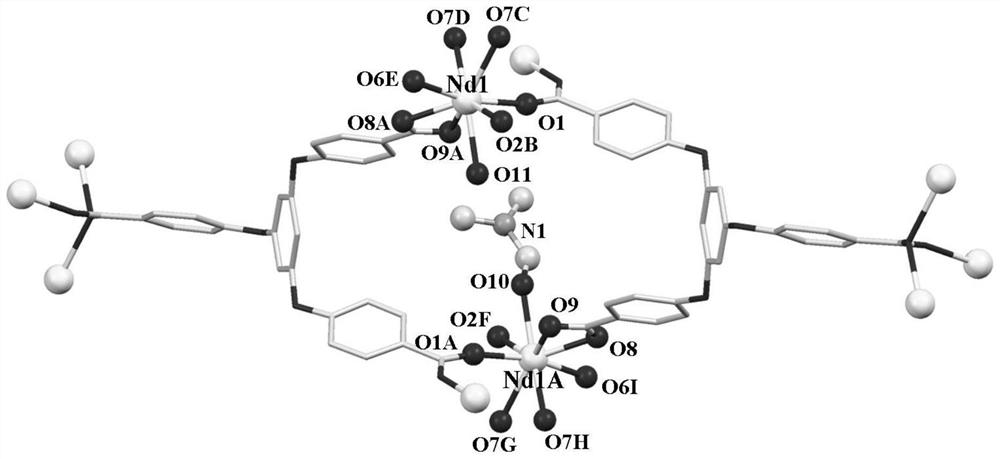

[0042] Structure determination of complex 1:

[0043] The crystal sample was fixed on the Bruker SMART 1000 CCD surface probe diffractometer, and the graphite monochromator MoKα was used as the radiation source, and the sample was collected for a wavelength of X-Ray diffraction data. In the ω-scan mode, the diffraction data...

Embodiment 2

[0052] The synthesis method of neodymium complex 1 is the same as that in Example 1.

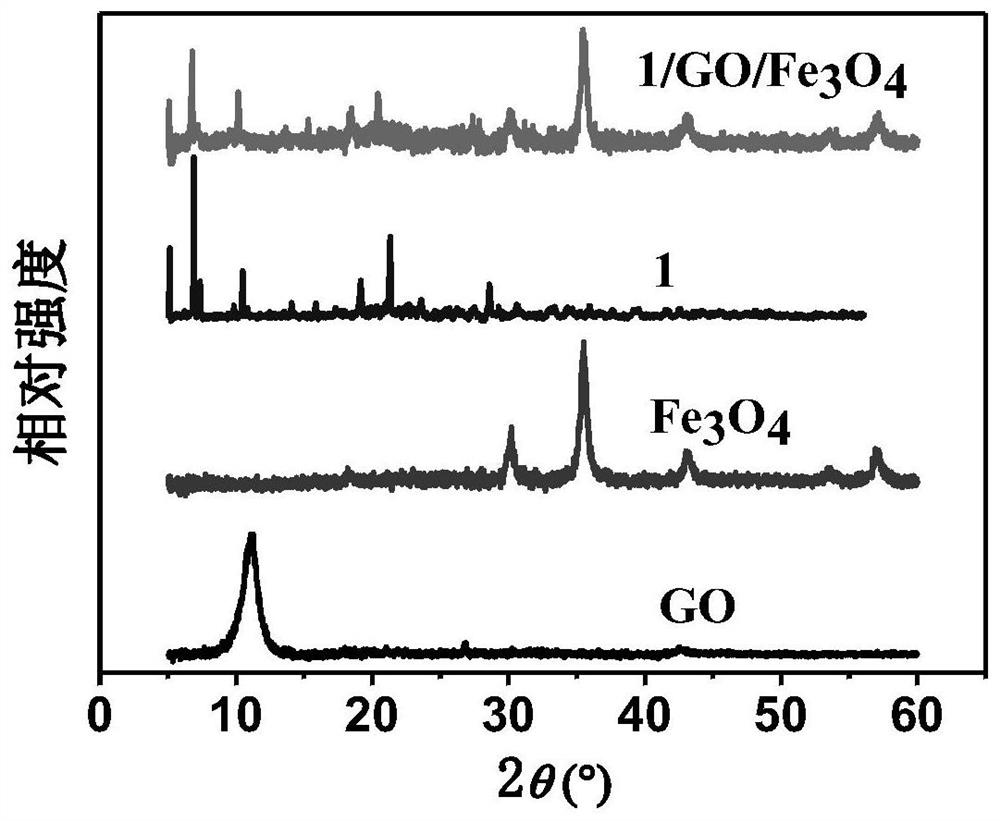

[0053] Preparation of complex:

[0054] First, 80 mg of 1 was dispersed in 3 mL of ethanol and sonicated for 15 min. Disperse 20 mg of GO in 10 ml of ethanol, ultrasonicate for 15 minutes, add to the above dispersion, reflux for 4 hours and dry, take 5 mg of dried product and add 6 mg of Fe 3 o 4 Sonicate for 1 hour, centrifuge, and collect 1 / GO / Fe 3 o 4 -9 Magnetic nanocomposites.

Embodiment 3

[0056] The synthesis method of neodymium complex 1 is the same as that in Example 1.

[0057] Preparation of complex:

[0058] First, 40 mg of 1 was dispersed in 3 mL of ethanol and sonicated for 15 min. Disperse 20 mg of GO in 10 ml of ethanol, ultrasonicate for 15 minutes, add to the above dispersion, reflux for 4 hours and dry, take 5 mg of dried product and add 6 mg of Fe 3 o 4 Sonicate for 1 hour, centrifuge, and collect 1 / GO / Fe 3 o 4 -15 Magnetic nanocomposites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com