Sulfur filler-based composite denitrification reactor and denitrification treatment technology

A reactor, sulfur-based technology, used in anaerobic digestion treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems affecting the normal operation of the biological flora active reaction system, and reduce sulfate radicals The amount of ions, improving the removal rate, and the effect of good removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

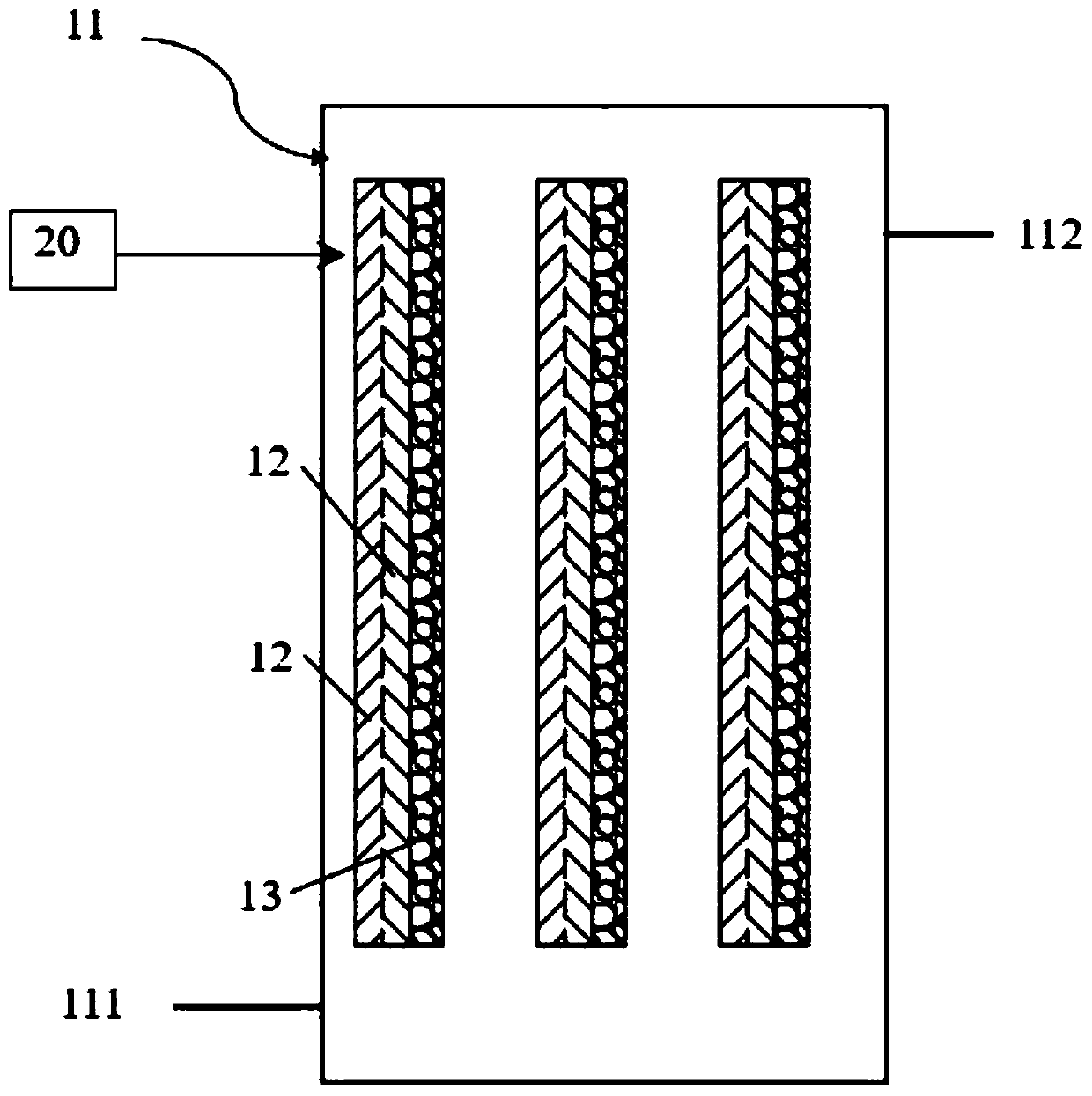

[0044] The ammonia nitrogen wastewater treatment process of the present embodiment uses a kind of such as figure 1 The composite denitrification reactor 10 shown, the composite denitrification reactor 10 includes at least one reactor main body 11, and biofilm filler 12 and sulfur-based solid filler 13 are installed in the reactor main body 11. The biofilm filler 12 and the sulfur-based solid filler 13 are stacked in the reactor, or the two are first assembled into a whole and then installed into the reactor main body 11 . The reactor body 11 is connected with a pH adjustment system 20 . The pH adjustment system 12 can monitor the pH value in the reactor main body 11 in real time, and start the electric pump according to the monitoring result, and inject the pH adjustment agent into the reactor main body 11 . The reactor body 11 is provided with a water inlet 111 and a water outlet 112 . The water inlet 111 is located at the lower part of the reactor main body 11 , and the wa...

Embodiment 2

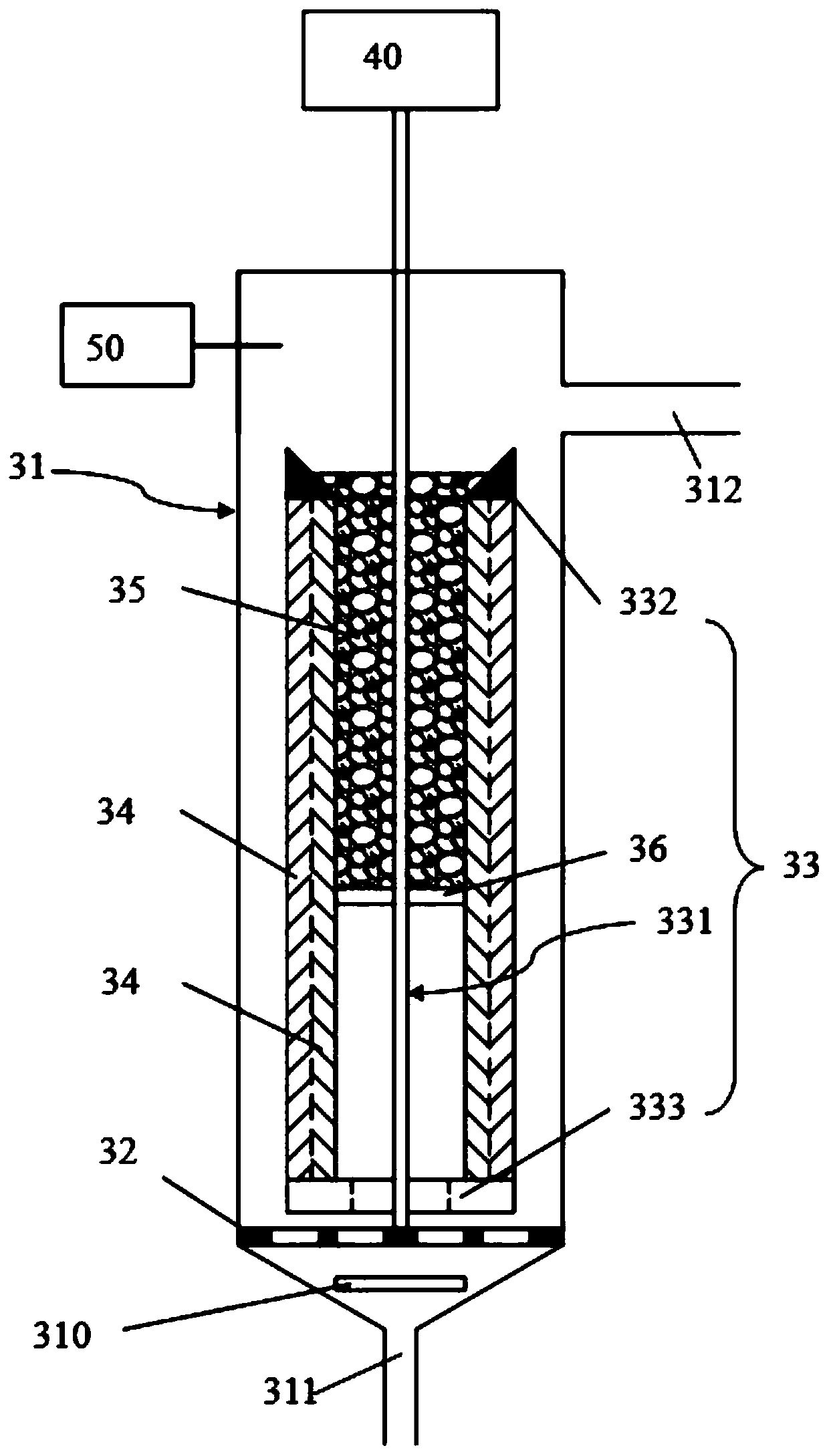

[0054] The ammonia nitrogen wastewater treatment process of the present embodiment uses a kind of such as figure 2 The composite denitrification reactor 30 shown, the composite denitrification reactor 30 includes at least one reactor main body 31, a support plate 32 is provided at the inner bottom of the reactor main body 31, and several water distribution holes are provided on the support plate 32, so The support plate 32 is also used as a water filling plate. The bottom of the reactor main body 31 is provided with a water inlet 311 and an aeration device 310 , the aeration device 310 is located between the water inlet 311 and the support plate 32 , and the water outlet 312 is located on the top of the side wall of the reactor main body 31 . Therefore, the water enters the middle of the bottom and the water exits from the top side. A packing frame 33 is arranged on the support plate 32 , and the packing frame includes a column 331 , a top fixing part 332 and a bottom fixing...

Embodiment 3

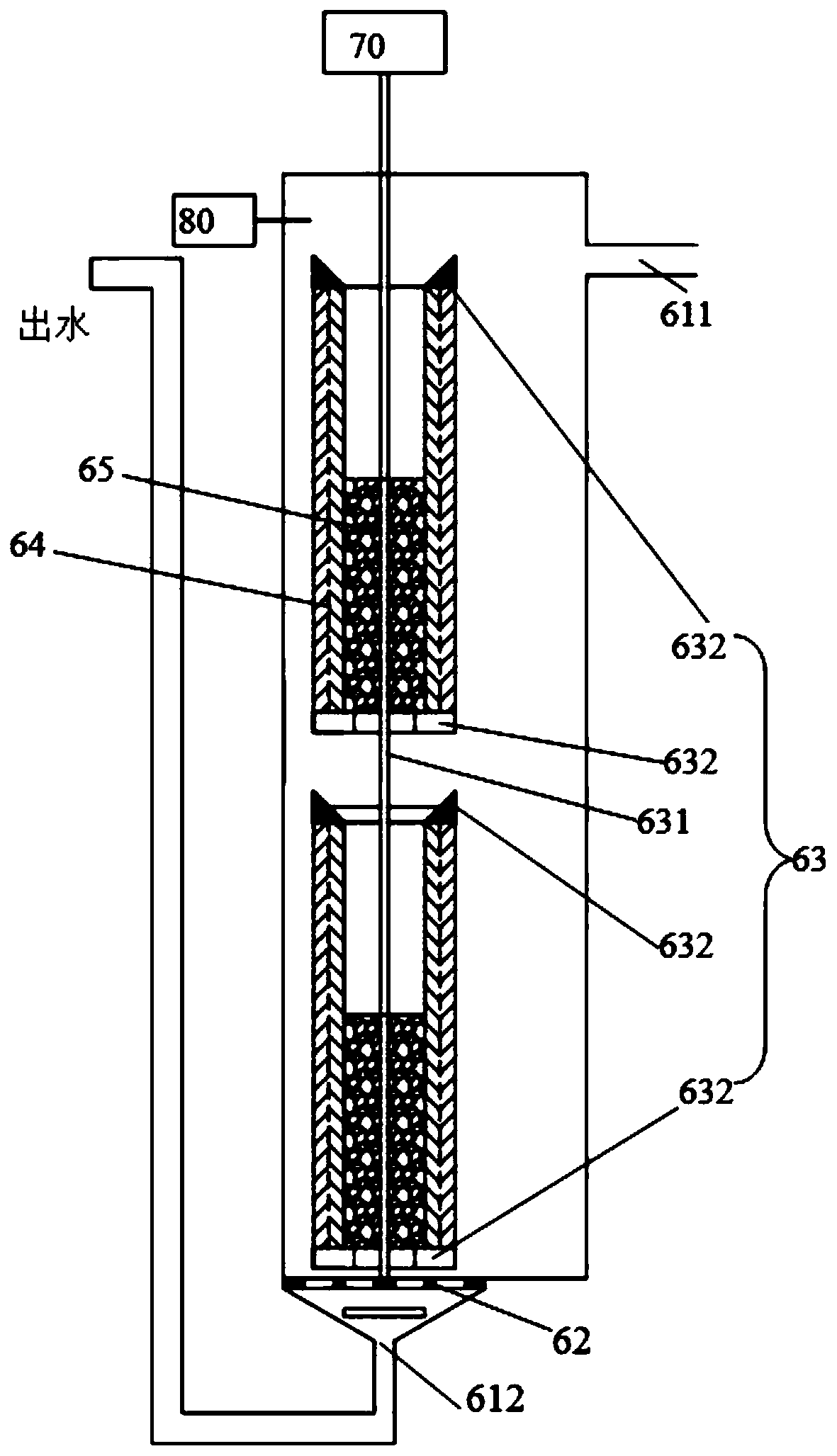

[0066] The ammonia nitrogen wastewater treatment process of the present embodiment uses a kind of such as image 3 The composite denitrification reactor 60 is shown. Such as image 3 As shown, the composite denitrification reactor 60 of this embodiment is based on the embodiment 2, and a combination of multiple groups of biofilm fillers and sulfur-based solid fillers connected in series.

[0067] The composite denitrification reactor 60 includes at least one reactor main body 61. A support plate 62 is provided at the inner bottom of the reactor main body 61. Several water outlet holes are provided on the support plate 62, so the support plate 62 can conduct flow. The upper end of the reactor main body 61 is provided with a water inlet 611 , and the bottom end is provided with a water outlet 612 . A packing frame 63 is arranged on the support plate 62 . The packing frame 63 includes a column 631 and two pairs of fixing pieces 632, and two fixing pieces in each pair of fixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com