Method for preparing cement grinding aid by utilizing landfill leachate

A technology for cement grinding aid and landfill leachate, which is applied in the field of hazardous waste recycling, can solve the problems of increased production cost of cement grinding aid, achieve harmless treatment, promote recycling and save production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] First, add 5.5Kg of sodium thiosulfate into 25.5Kg of water and stir. After completely dissolving, add 20Kg of landfill leachate and the filtrate after alkali reaction to it for stirring and homogenization, and then add 3Kg of consistency regulator, 1Kg Add the coupling agent into it and stir well, then add 20Kg of polyol into it and stir to dissolve, then add 15Kg of molasses to make it fully dissolved, and finally add 10Kg of stabilizer into it and stir evenly to get the finished cement grinding aid.

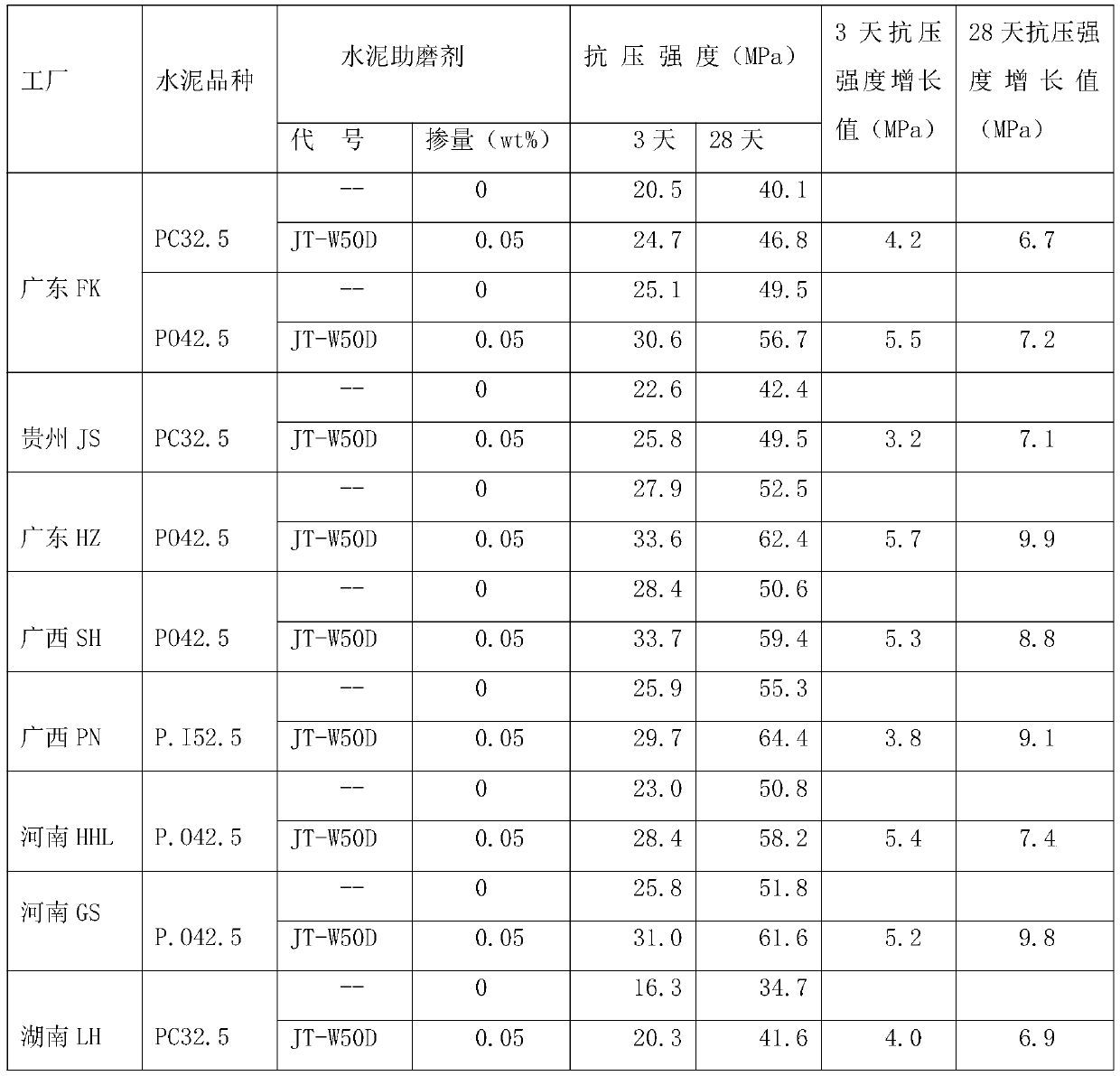

[0075] Take cement samples from different provinces, different cement manufacturers, and different varieties, and add the cement grinding aid respectively. The cement grinding aid prepared in Example 1 is added in a mass percentage of 0.05% in cement, according to GB / T17671-1999 " Cement mortar strength test method (ISO) method " carries out blending forming test, to verify this cement grinding aid to cement 3 days, 28 days compressive strength increasing effect, embodim...

Embodiment 2

[0080] First, add 6.0Kg of sodium thiosulfate into 23Kg of water and stir. After completely dissolving, add 20Kg of landfill leachate and the filtrate after alkali reaction to it for stirring and homogenization, and then add 4Kg of consistency regulator, 2Kg of Add the joint agent into it and stir well, then add 20Kg of polyol into it and stir to dissolve, then add 15Kg of molasses to make it fully dissolved, and finally add 10Kg of stabilizer into it and stir evenly to get the finished cement grinding aid.

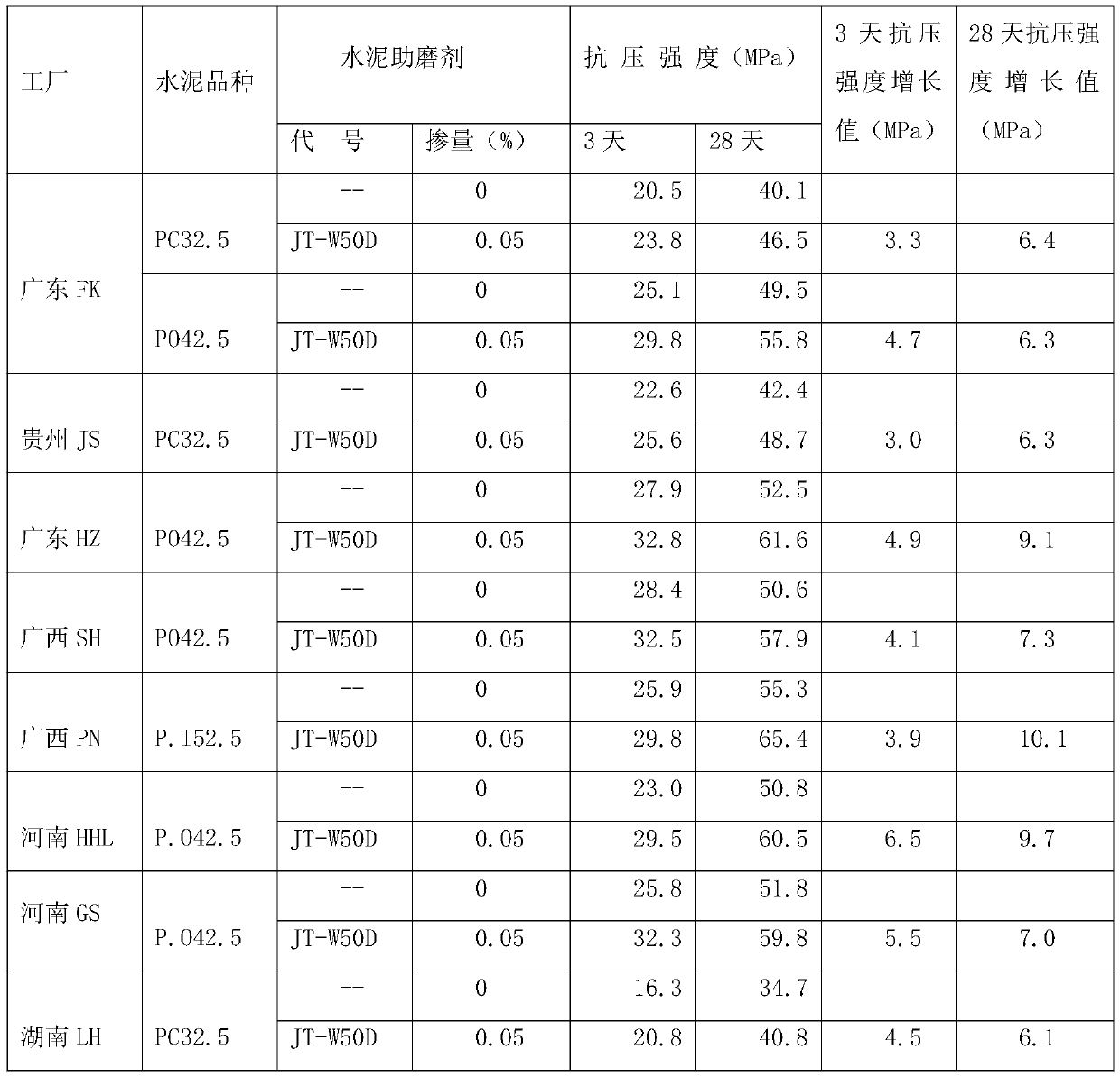

[0081] Take cement samples from different provinces, different cement manufacturers, and different varieties, and add this cement grinding aid respectively. The cement grinding aid prepared in this embodiment 2 is added in a mass percentage of 0.05% in cement, according to GB / T17671-1999 " Cement mortar strength test method (ISO) method " carries out blending forming test, to verify this cement grinding aid to cement 3 days, 28 days compressive strength increasing effect, ...

Embodiment 3

[0086] First, add 7Kg of sodium thiosulfate into 23.5Kg of water for stirring, and after completely dissolving, add 20Kg of landfill leachate and the filtrate after alkali reaction into it for stirring and homogenization, and then add 3Kg of consistency regulator, 1.5Kg Add the coupling agent into it and stir well, then add 20Kg of polyol into it and stir to dissolve, then add 15Kg of molasses to make it fully dissolved, and finally add 10Kg of stabilizer into it and stir evenly to get the finished cement grinding aid.

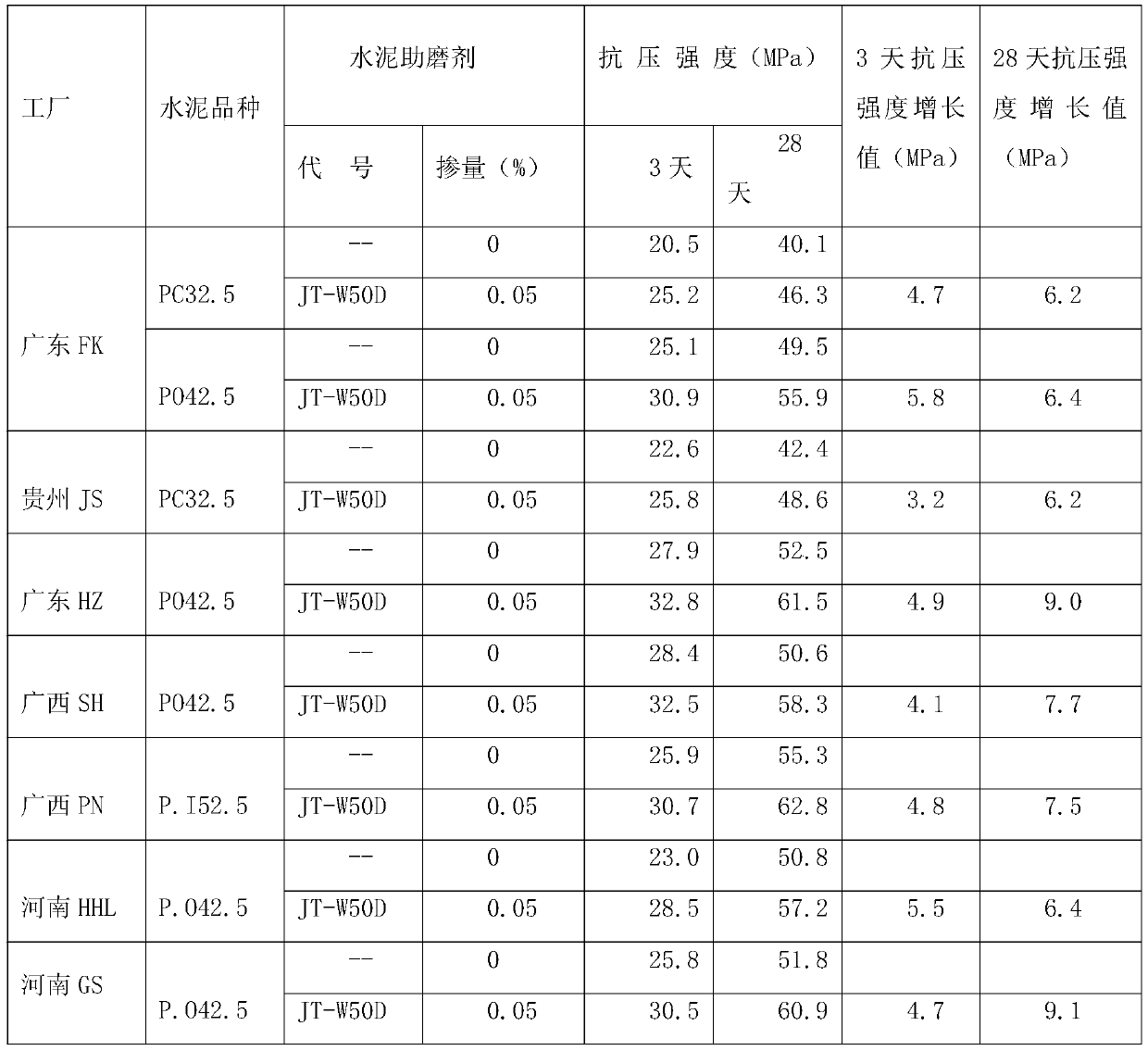

[0087] Take cement samples from different provinces, different cement manufacturers, and different varieties, and add this cement grinding aid respectively. The cement grinding aid prepared in this embodiment 3 is added in a mass percentage of 0.05% in cement, according to GB / T17671-1999 " Cement mortar strength test method (ISO) method " carries out blending forming test, to verify this cement grinding aid to cement 3 days, 28 days compressive strength increas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com