Electrolytic cell with uniform vertical inflowing feeding

An electrolytic cell and a uniform technology, applied in the field of electrolytic cells with uniform vertical inflow feeding, can solve the problems of unfavorable anode mud particle settlement, uneven liquid flow distribution, and affecting the quality of the cathode, so as to facilitate high current density electrolysis production and eliminate concentrated The effect of poor polarization and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

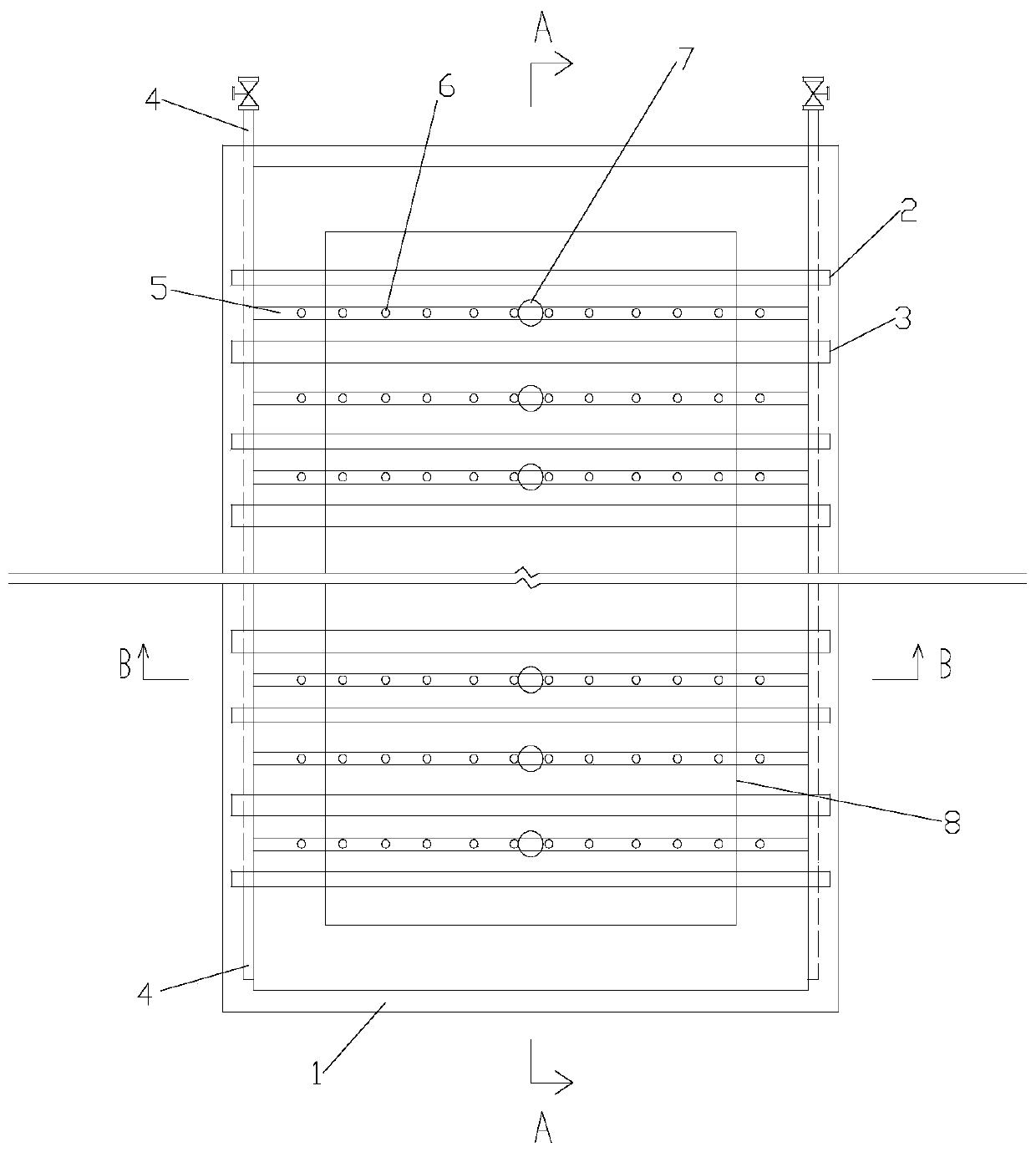

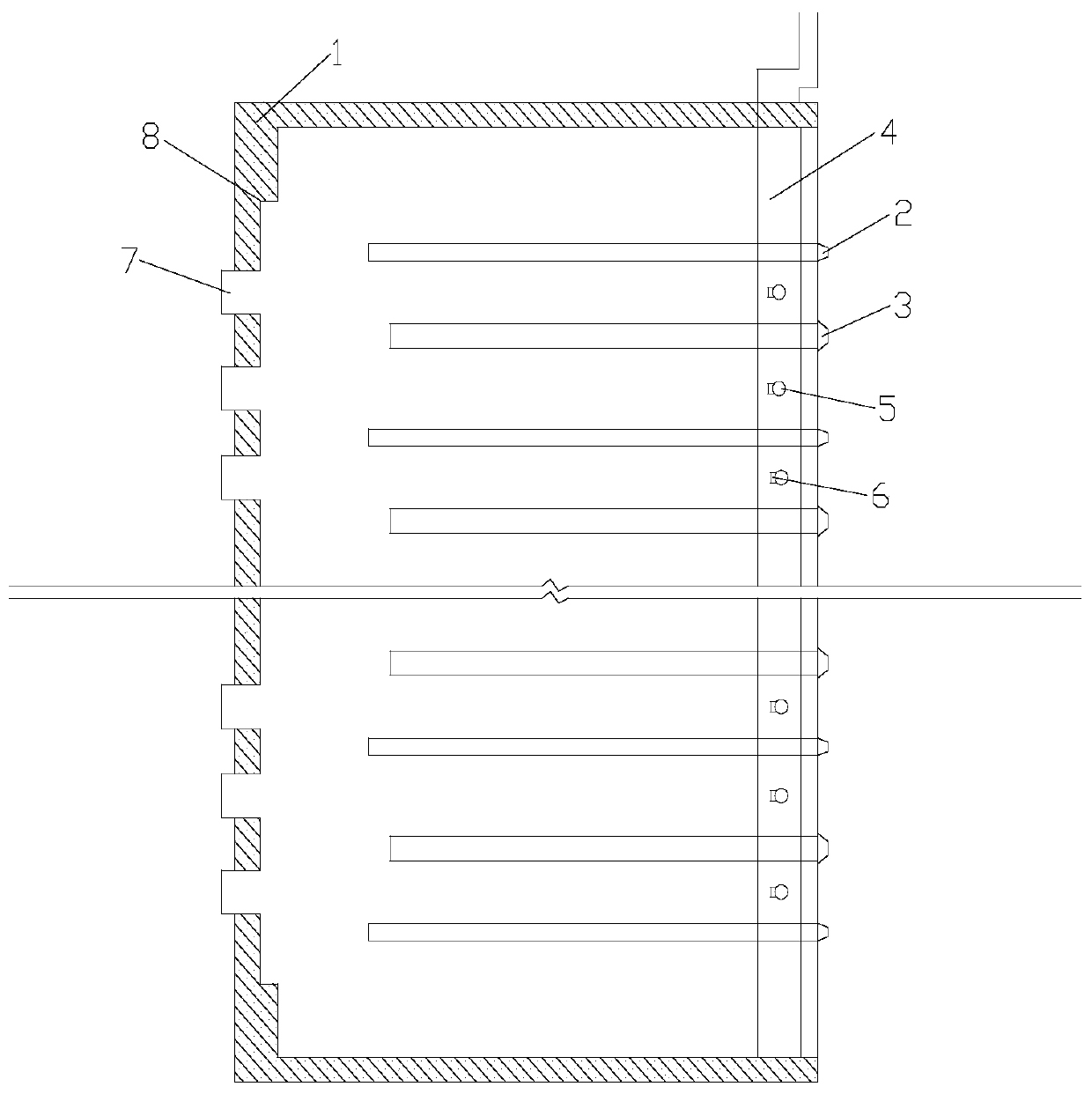

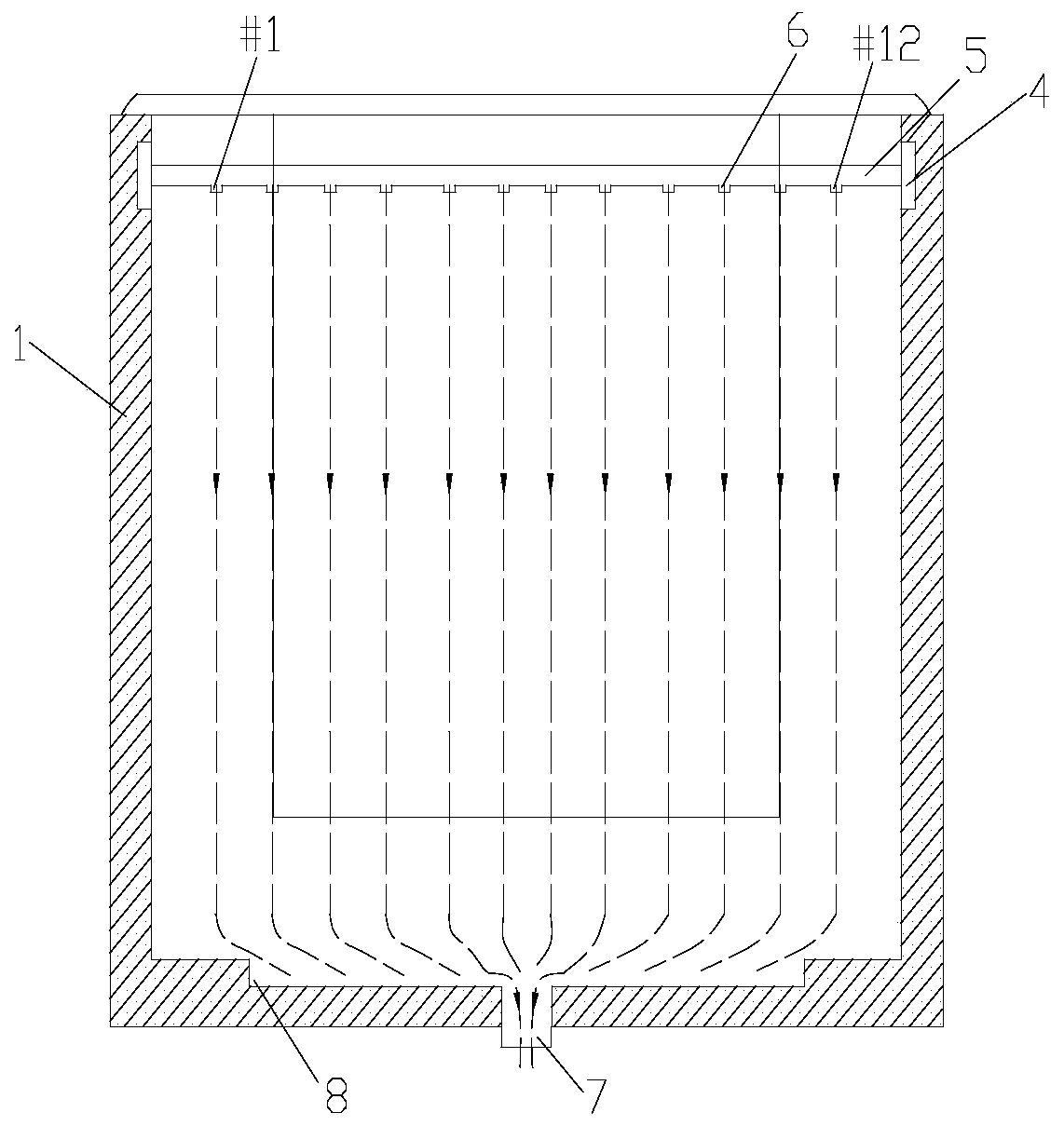

[0021] An electrolytic cell with uniform vertical inflow feeding, such as figure 1 , figure 2 , image 3 As shown, it includes an electrolytic cell body 1, a plurality of cathode plates 2, a plurality of anode plates 3, a solution channel I4, a solution channel II 5, a plurality of liquid inlet nozzles 6, a plurality of liquid outlet nozzles 7, and a rectangular Groove 8.

[0022] Such as image 3 As shown, the liquid inlet nozzles installed on the solution channel Ⅱ5 are respectively named #1 to #12 from left to right. In this embodiment, a single electrolytic cell is used as an object, and a total of 12 liquid inlet nozzles #1-#12 are used to feed liquid at the same time. On this basis, the orthogonal experiments with two factors and two levels were carried out. Among them, current density: 240 A / m 2 ,300A / m 2 ; Electrolyte flow rate: 11ml / min, 22ml / min. The period of each experiment is two days. After the experiment, ICP is used to detect and analyze the content of...

Embodiment 2

[0026] A total of 10 liquid inlet nozzles #2-#11 were used as solution inlets to feed liquid at the same time, and the condition experiment in Example 1 was repeated, and the analysis results are shown in Table 2.

[0027] Impurity content in the cathode copper of table 2 (unit: ppm)

[0028]

Embodiment 3

[0030] Using #3-#10, a total of 8 liquid inlet nozzles as solution inlets to feed liquid at the same time, repeat the above experiment, and the analysis results are shown in Table 3.

[0031] Impurity content in the cathode copper of table 3 (unit: ppm)

[0032]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap