Plastic part electroplating method and plastic part electroplating pre-impregnation device

A technology of plastic parts and prepreg, which is applied in the electrolysis process, electrolysis components, liquid chemical plating, etc., can solve the problems of detonation of explosive hooks, easy formation of sand spots on the surface of products, impurity pollution, etc., achieving complete electrolysis and reducing sand The effect of spot defects and reducing impurity contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

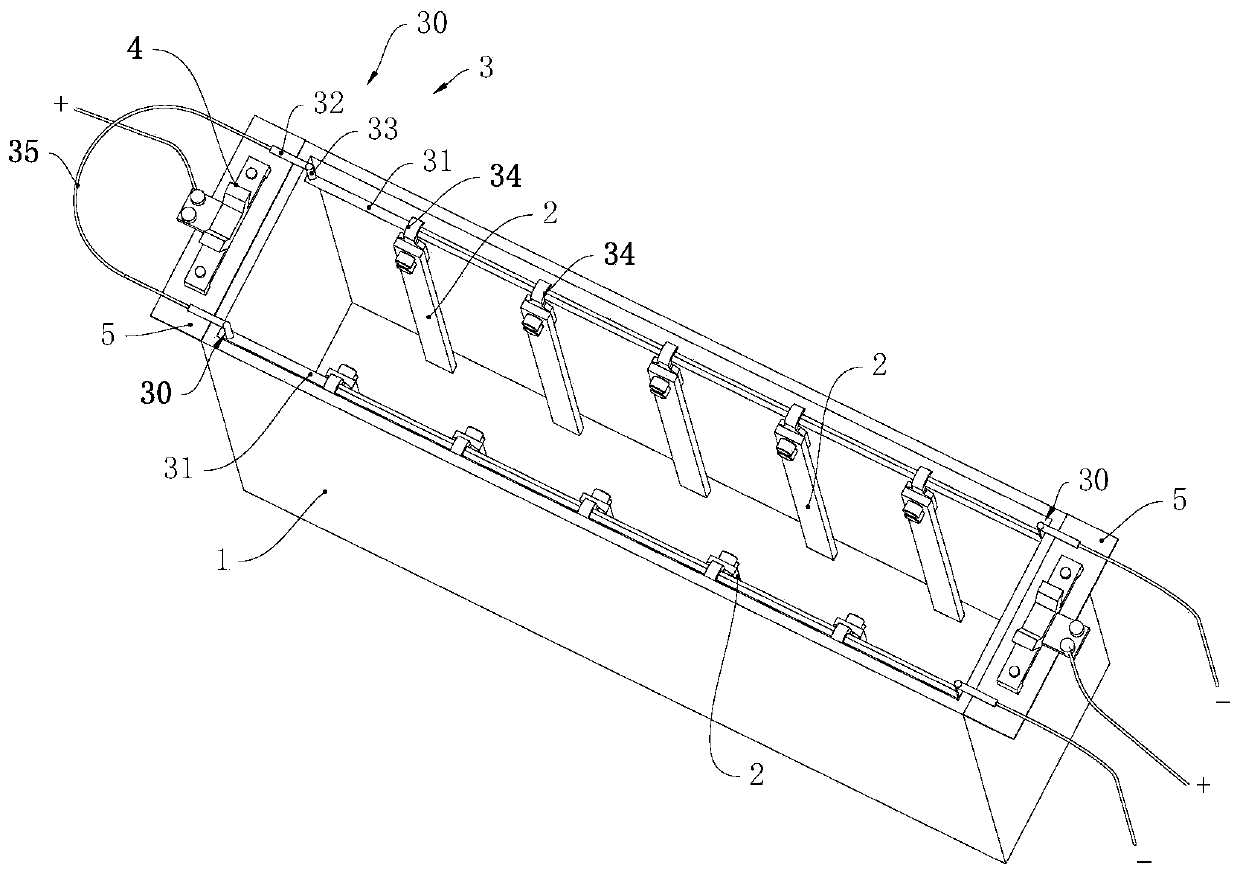

[0033] see figure 1 , The electroplating prepreg device for plastic parts of the present invention includes an electroplating tank 1 , a plurality of electrolytic plates 2 and a conductive support assembly 3 , and the conductive support assembly 3 erects a plurality of electrolytic plates 2 in the electroplating tank 1 . The electroplating tank 1 is used to load the pre-soaking solution. The electroplating tank 1 is provided with a conductive part 4, through which the pre-dip solution is energized. The conductive part 4 is connected to the positive pole of the power supply, and the electrolytic plate 2 is connected to the negative pole of the power supply. The electroplating tank 1 is equipped with a pre-dip liquid, which is a hydrochloric acid solution, and the hanger and the plastic parts on the hanger are all soaked in the pre-dip liquid, and the pre-dip liquid is energized through the conductive part 4, and the conductive part 4 is connected to the positive electrode. At t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap