Virtual debugging system based on iopenworks

A debugging system and robot technology, applied in the program control of the sequence/logic controller, comprehensive factory control, electrical program control, etc., can solve the problems of cumbersome and inconvenient operation, no interaction, no simulation software feedback, etc., to achieve High-speed and stable data transmission, easy to view and manage data, and improve the effect of correctness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

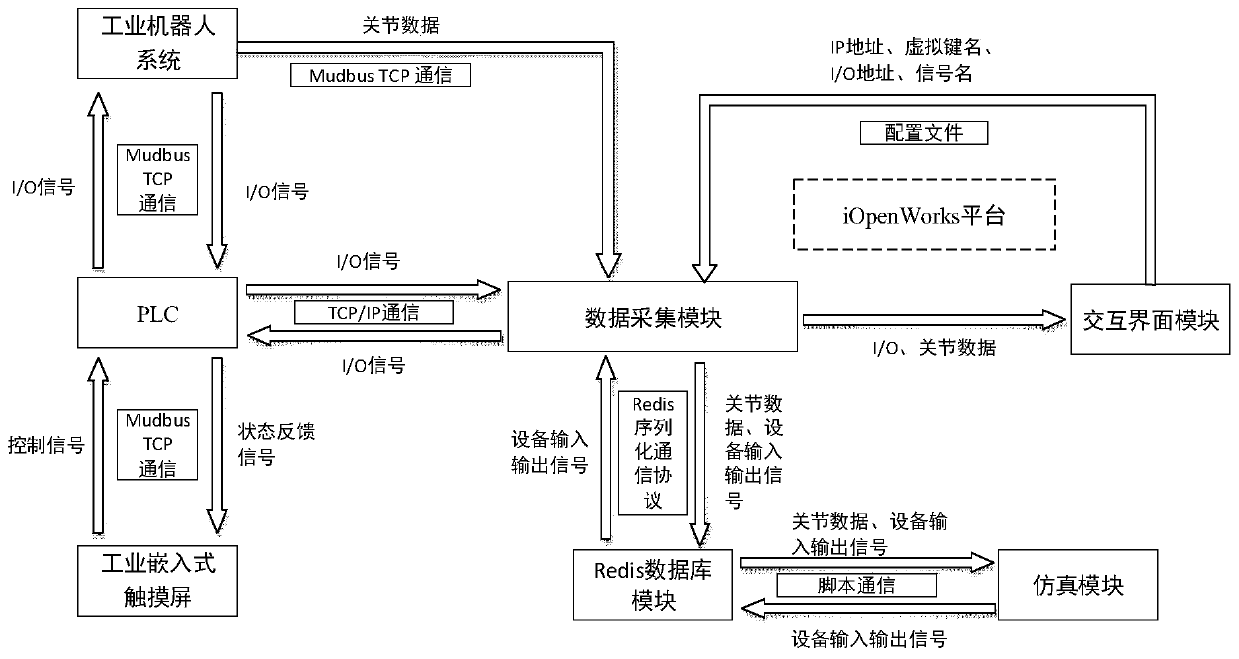

[0028] combine figure 2 And Fig. 3, the specific implementation mode of the patent of the present invention is as follows:

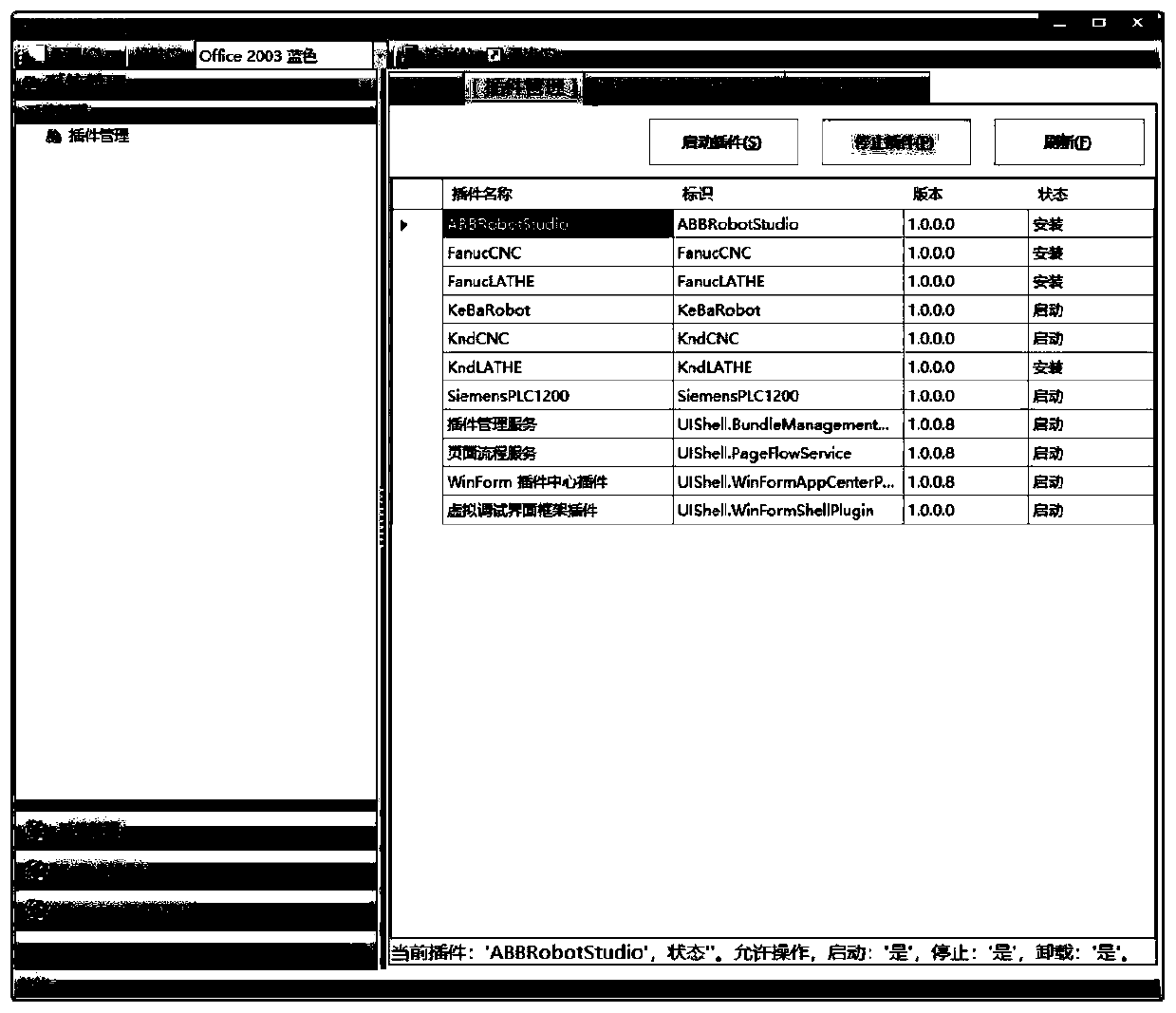

[0029] PC client, Redis database and simulation software are installed on the computer, according to the figure 1 After the virtual debugging platform is set up, the virtual debugging operation can be carried out.

[0030] 1) The industrial robot system adopts KEBA industrial robot, including KEBA robot controller and teaching box, powered by +24V by NDR-240 rail type power supply, and loads the robot program into the CF card by using the CF card reader , and then load the CF card into the robot controller, and select the corresponding robot program from the robot teaching box; connect the PLC and the industrial embedded touch screen to the local area network under the same switch. After the connection is successful, the KEBA industrial robot will communicate with the PLC. Mudbus TCP communication connection, at the same time, the data acquisition mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com