Catalytic cracking device optimization method based on data model

A catalytic cracking unit and optimization method technology, applied in the directions of comprehensive plant control, comprehensive plant control, electrical program control, etc., can solve the problems of increasing invalid variables, difficult establishment, slow calculation speed, etc., so as to improve model accuracy and ensure absolute accuracy. The effect of convergence and short acquisition interval

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

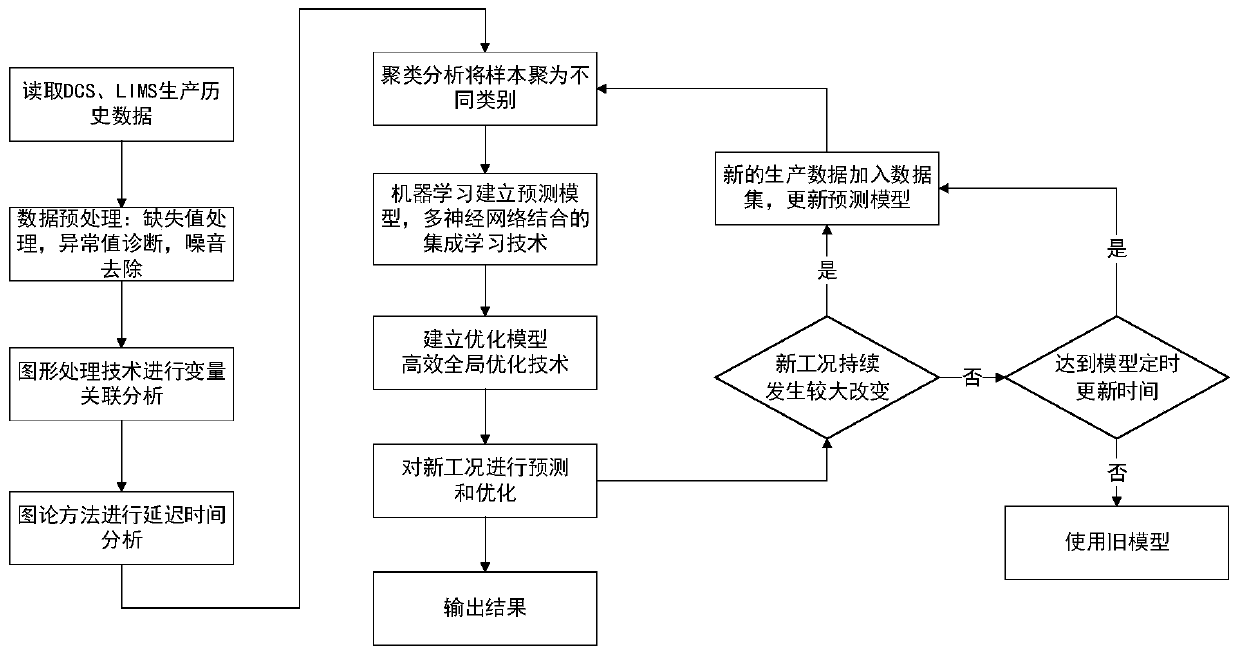

[0041] Example: such as figure 1 As shown, a data model-based catalytic cracking unit optimization method includes the following steps:

[0042] (1) Establish a production history database. Read the complete historical data of the DCS system and LIMS detection of the catalytic cracking unit for nearly a year, the production process parameter data is automatically recorded every 1 minute, and the device system outlet composition and product material property detection data are analyzed every 4 hours. Organize and merge the original data of DCS system and LIMS system, and establish a well-formatted database to ensure that the two types of data are easy to read in subsequent analysis.

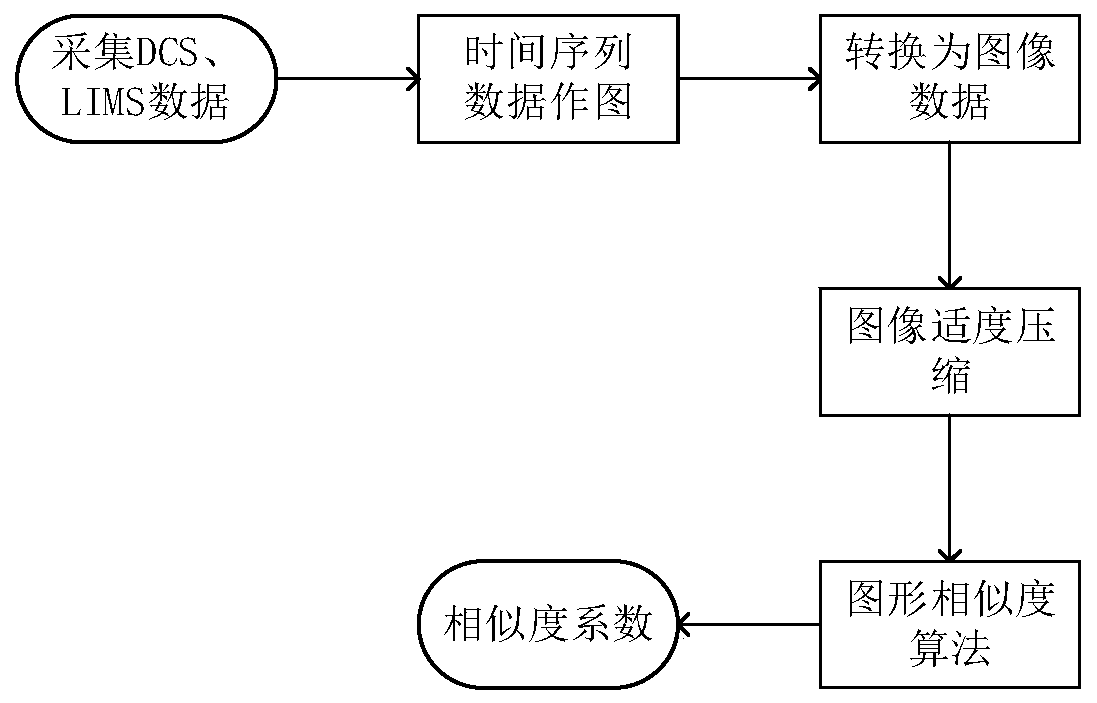

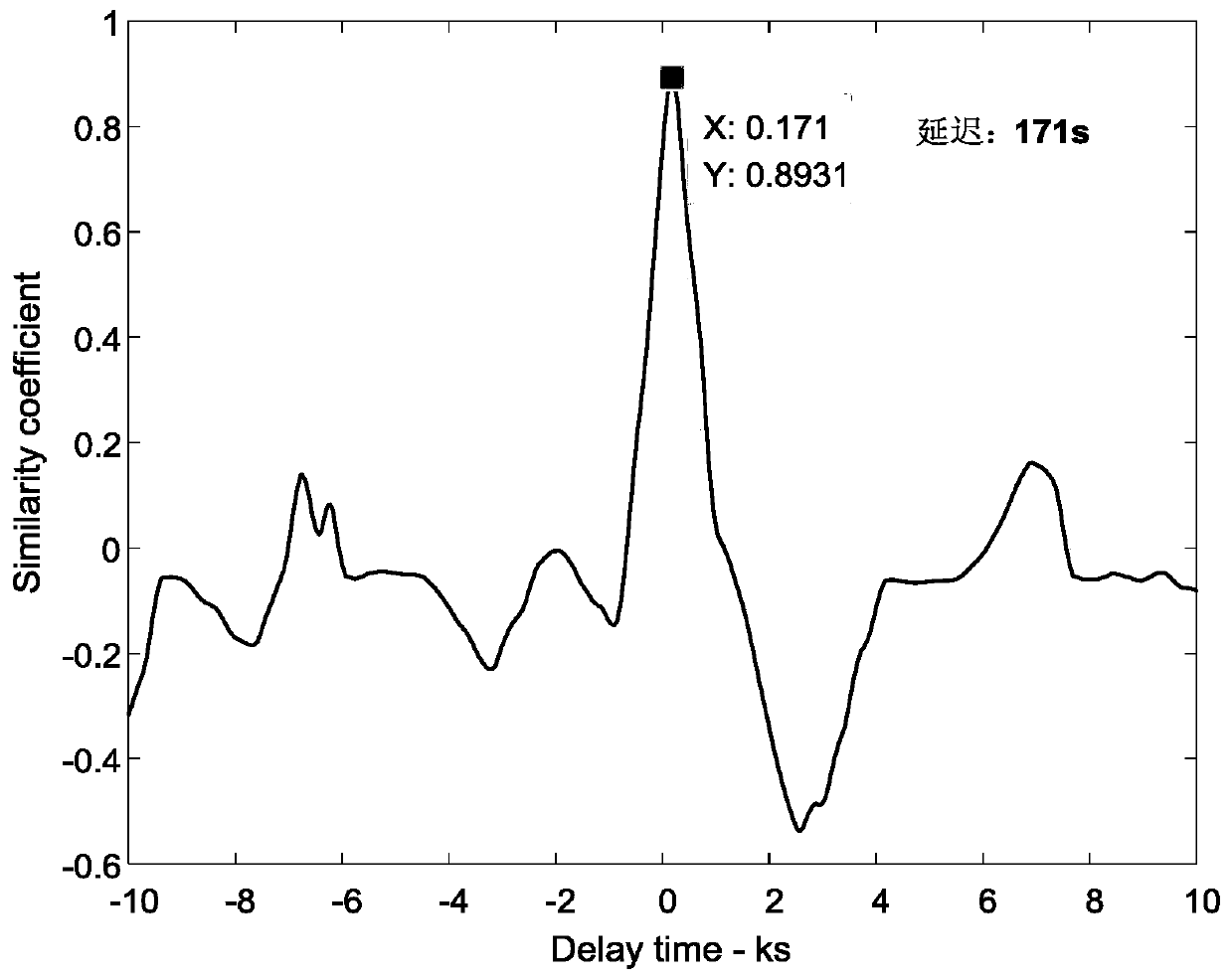

[0043] (2) Data extraction and preprocessing. Perform descriptive statistical analysis on the collected DCS production process parameter data and LIMS material property detection data, analyze the distribution characteristics, types, and statistical significance of the data, and judge whether th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com