Method and apparatus for testing a thin film transistor panel

A technology for transistor substrates and thin film transistors, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., and can solve problems such as distortion, signal attenuation, and cost increase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

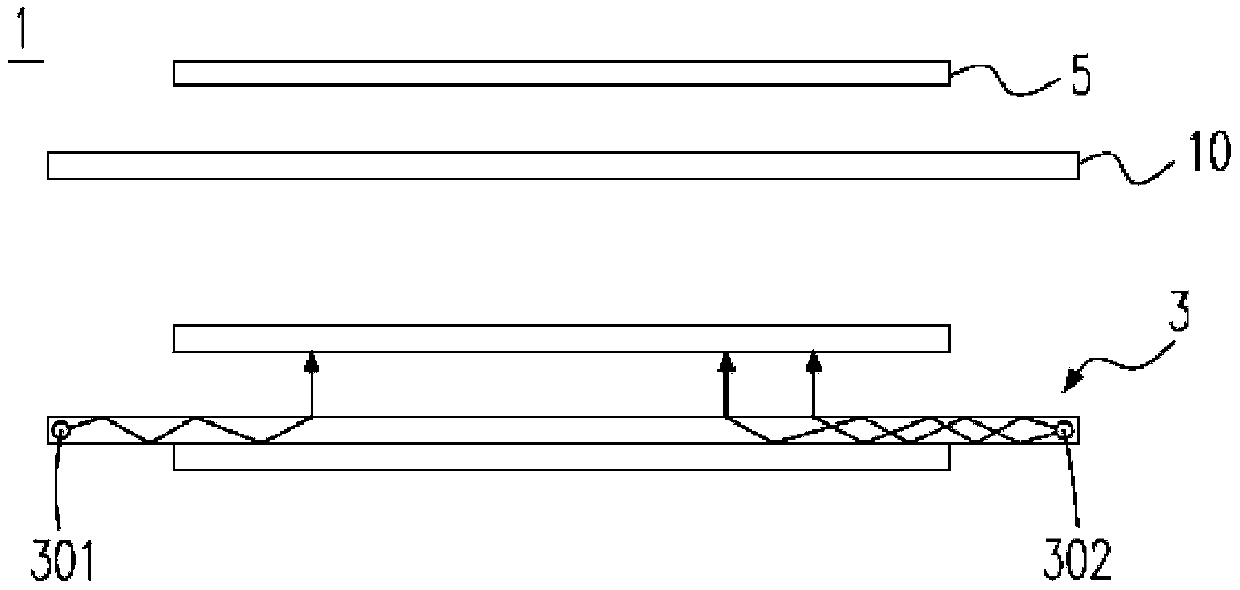

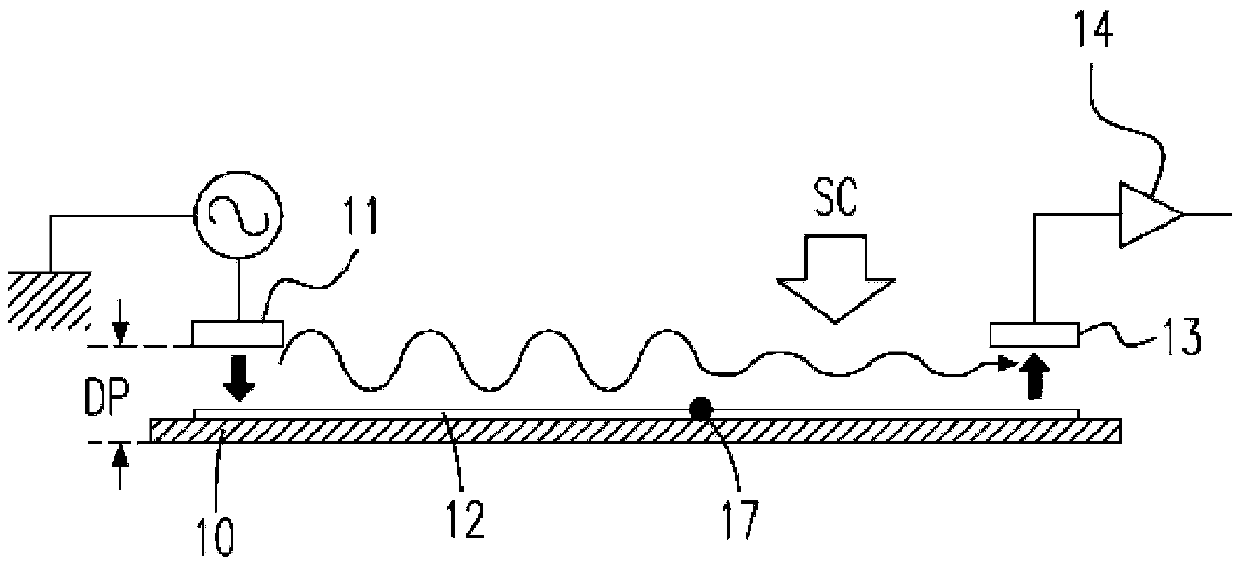

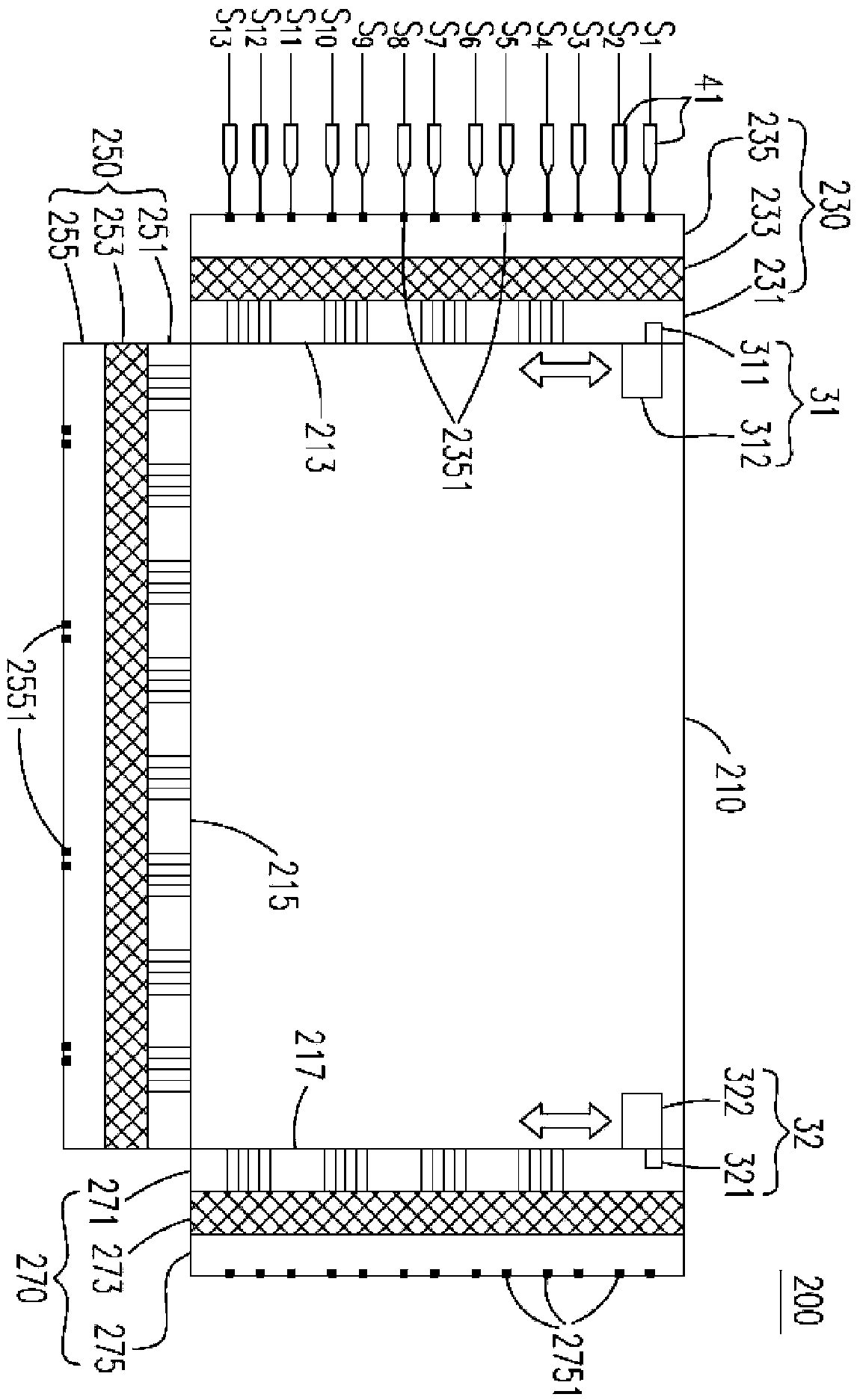

[0031] 1. A method for detecting a thin film transistor substrate, wherein the thin film transistor substrate includes at least one display area and a peripheral area surrounding the display area, the peripheral area has a plurality of function test signal input pads, the method Include:

[0032] Provide multiple probes and a sensing unit;

[0033] respectively disposing the plurality of probes on the plurality of functional test signal input pads to apply a set of test electrical signals to the plurality of functional test signal input pads; and

[0034] The sensing unit is arranged at a sensing position adjacent to an edge of the display area, and sequentially receives sensing signals along the edge in a non-contact manner.

[0035] 2. The method of embodiment 1, wherein the display area has a first display side and a second display side, the peripheral area has a first peripheral side and a second peripheral side, the first display side and the first peripheral side belon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com