A kind of preparation method of negative electrode composite material of lithium ion battery

A lithium ion battery and composite material technology, which is applied in the field of preparation of lithium ion battery negative electrode composite materials, can solve the problems of insufficient contact between graphite and silicon oxide, and the influence of the discharge capacity of lithium battery negative electrode materials, so as to improve the bonding force and solve the Combination is difficult, the effect of improving the discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

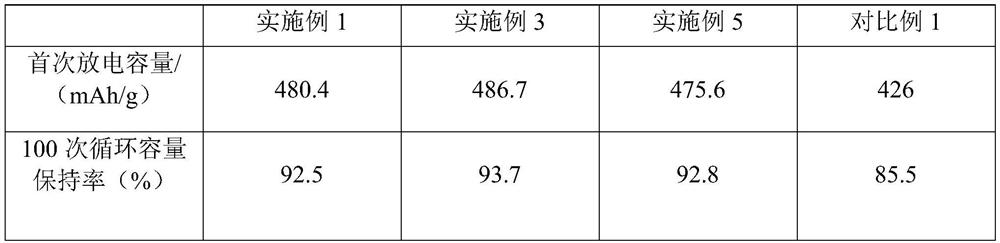

Examples

Embodiment 1

[0022] The preparation method of negative electrode composite material of lithium ion battery comprises the following steps:

[0023] 1) phenolic resin is dissolved in ethanol and is mixed with phenolic resin solution, and the mass volume ratio of phenolic resin and ethanol is 1:13g / mL; Carboxymethyl chitosan is dissolved in water and is mixed with carboxymethyl chitosan that mass concentration is 1wt%. base chitosan solution;

[0024] 2) After mixing graphite and silicon oxide, carry out ball milling to obtain mixed powder a, the mass ratio of silicon oxide and graphite is 5:98; add mixed powder a to the carboxymethyl chitosan solution in the step 1), The mass ratio of the mixed powder a to the carboxymethyl chitosan solution is 1:30, left to stand for 25min, filtered and dried successively to obtain the powder b;

[0025] 3) Add the powder b in the step 2) into the phenolic resin solution, the mass ratio of the powder b to the phenolic resin solution is 1:15, stir and mix e...

Embodiment 2

[0028] The preparation method of negative electrode composite material of lithium ion battery comprises the following steps:

[0029] 1) phenolic resin is dissolved in ethanol and is mixed with phenolic resin solution, and the mass volume ratio of phenolic resin and ethanol is 1:11g / mL; Carboxymethyl chitosan is dissolved in water and is mixed with the carboxymethyl chitosan that mass concentration is 0.5wt%. Methyl chitosan solution;

[0030] 2) After mixing graphite and silicon oxide, carry out ball milling to obtain mixed powder a, the mass ratio of silicon oxide and graphite is 5:96; add mixed powder a to the carboxymethyl chitosan solution in the step 1), The mass ratio of mixed powder a to carboxymethyl chitosan solution is 1:25, left standstill for 22min, filtered and dried successively to obtain powder b;

[0031] 3) Add the powder b in the step 2) into the phenolic resin solution, the mass ratio of the powder b to the phenolic resin solution is 1:12, stir and mix eve...

Embodiment 3

[0034] The preparation method of negative electrode composite material of lithium ion battery comprises the following steps:

[0035] 1) phenolic resin is dissolved in ethanol and is mixed with phenolic resin solution, and the mass volume ratio of phenolic resin and ethanol is 1:14g / mL; Carboxymethyl chitosan is dissolved in water and is mixed with the carboxymethyl chitosan that mass concentration is 1.5wt%. Methyl chitosan solution;

[0036]2) After mixing graphite and silicon oxide, carry out ball milling to obtain mixed powder a, the mass ratio of silicon oxide and graphite is 5:100; add mixed powder a to the carboxymethyl chitosan solution in the step 1), The mass ratio of the mixed powder a to the carboxymethyl chitosan solution is 1:45, left to stand for 25min, filtered and dried successively to obtain the powder b;

[0037] 3) Add the powder b in the step 2) into the phenolic resin solution, the mass ratio of the powder b to the phenolic resin solution is 1:18, stir a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com