Lithium ion battery negative paste stabilizer and preparation method and application thereof

A lithium-ion battery, negative electrode slurry technology, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problem of battery negative electrode slurry stability not mentioned, slurry coating edge bulging, poor rheological stability and other problems, to achieve the effect of inhibiting slurry settlement, preventing bulging and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

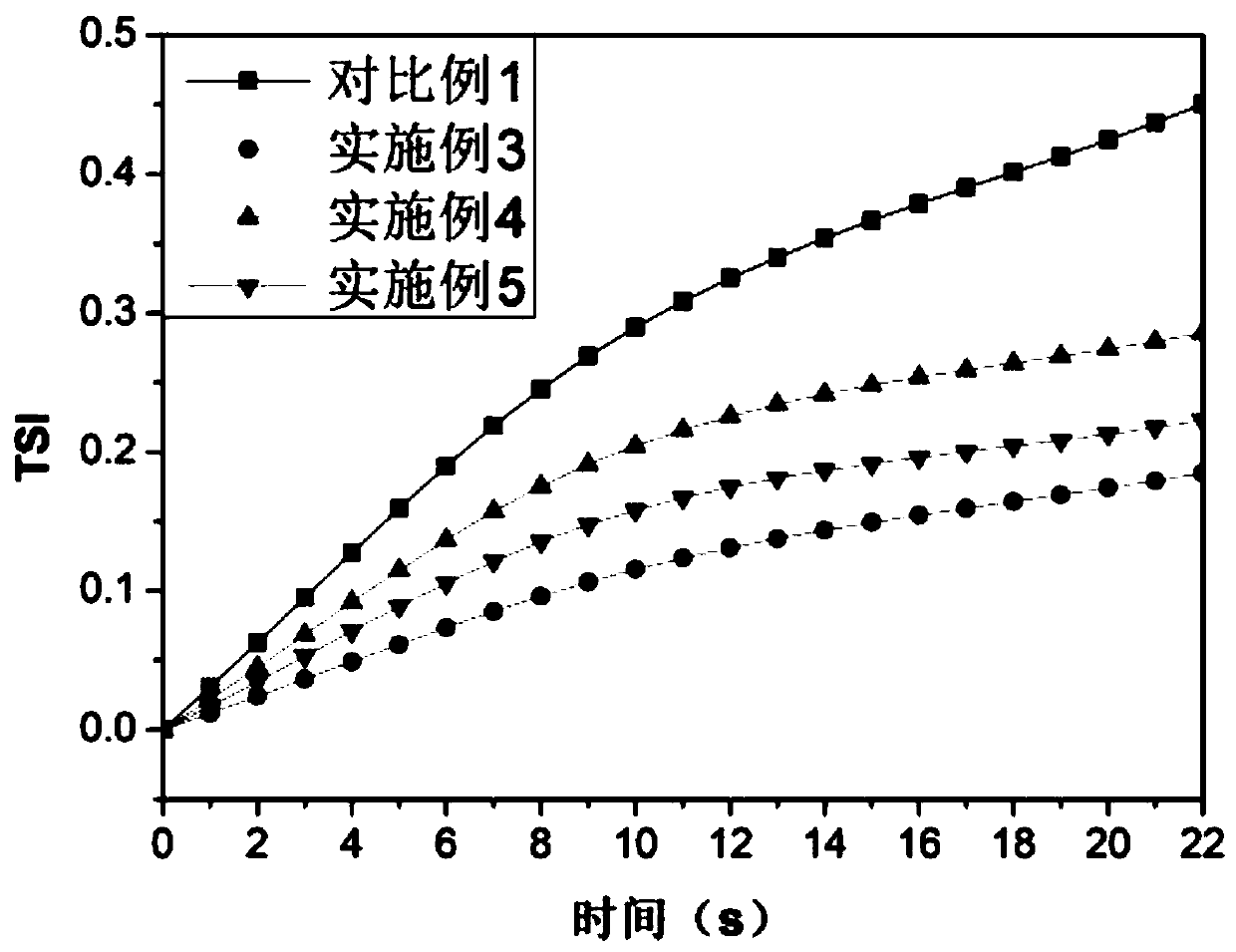

Examples

Embodiment 1

[0040] Embodiment 1: Lithium ion battery negative electrode slurry stabilizer, it comprises the following components: polyacrylonitrile and polar solvent, and described polyacrylonitrile is 0.1%~50% of polar solvent weight.

[0041] Preferably, the polyacrylonitrile is 0.1% by weight of the polar solvent;

[0042] Preferably, the polyacrylonitrile is 50% by weight of the polar solvent;

[0043] Preferably, the polyacrylonitrile is 35% by weight of the polar solvent;

[0044] Preferably, the polyacrylonitrile is 42% by weight of the polar solvent;

[0045] Wherein, the polar solvent is N-methylpyrrolidone;

[0046] Or the polar solvent is ethanol;

[0047] Or the polar solvent is a mixture of N-methylpyrrolidone and ethanol.

[0048] Wherein, the preparation method of the negative electrode slurry stabilizer of the lithium ion battery is: adding polyacrylonitrile powder into a polar solvent, stirring and dispersing the obtained solution, which is the negative electrode slur...

Embodiment 2

[0050] Lithium-ion battery negative electrode slurry, which includes the following components in weight percentage: 0.2% to 2.0% of CMC, 0.5% to 5% of negative electrode conductive agent, 90% to 98% of negative electrode active material, and 0.8% to 2.5% of SBR %, the stabilizer that embodiment 1 makes is 0.2%~5%. Wherein, the negative electrode conductive agent is one or a combination of two or more of acetylene black, carbon nanotubes, and graphene. The negative electrode active material is one or a combination of two or more of secondary granulated artificial graphite, natural graphite, lithium titanate and silicon carbon materials. Preferably, the negative electrode active material is a combination of secondary granulated artificial graphite and natural graphite in a ratio of 1:1.

[0051] Preferably, the components of the lithium-ion battery negative electrode slurry are respectively by weight percentage: 0.2% of CMC, 0.5% of negative electrode conductive agent, 90% of n...

Embodiment 3

[0057] The preparation of negative electrode slurry, its specific steps are:

[0058] S1: Add 1 kg of polyacrylonitrile powder into 99 kg of N-methylpyrrolidone in the first stirring vessel, and stir until uniform to obtain a stabilizer.

[0059] S2: Add 0.16kg CMC and 13.14g deionized water into the second stirring container and stir to prepare CMC glue;

[0060] S3: Add 0.21 kg of negative electrode conductive agent Super P (acetylene black) to the CMC glue, and stir evenly to prepare a conductive glue.

[0061] S4: Add 10kg of artificial graphite with secondary particles into the conductive adhesive solution, and stir evenly to prepare the negative electrode active material solution;

[0062] S5: Add 0.53 kg of SBR to the negative electrode active material liquid, and stir evenly to obtain a semi-finished product;

[0063] S6: Add 5.32 kg of the stabilizer prepared in step S1 to the semi-finished product, stir evenly, and adjust the viscosity of the slurry to 1500-4500 mP...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com