1000kv UHV Transformer Low Voltage Lead Disassembly Platform

A low-voltage lead, transformer technology, applied in switchgear, electrical components, etc., can solve the problems of inability to ensure the safety of personnel and equipment, slow operation process, time-consuming and laborious, etc., to reduce the risk of high-altitude work, stable standing space, and flexible structural design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

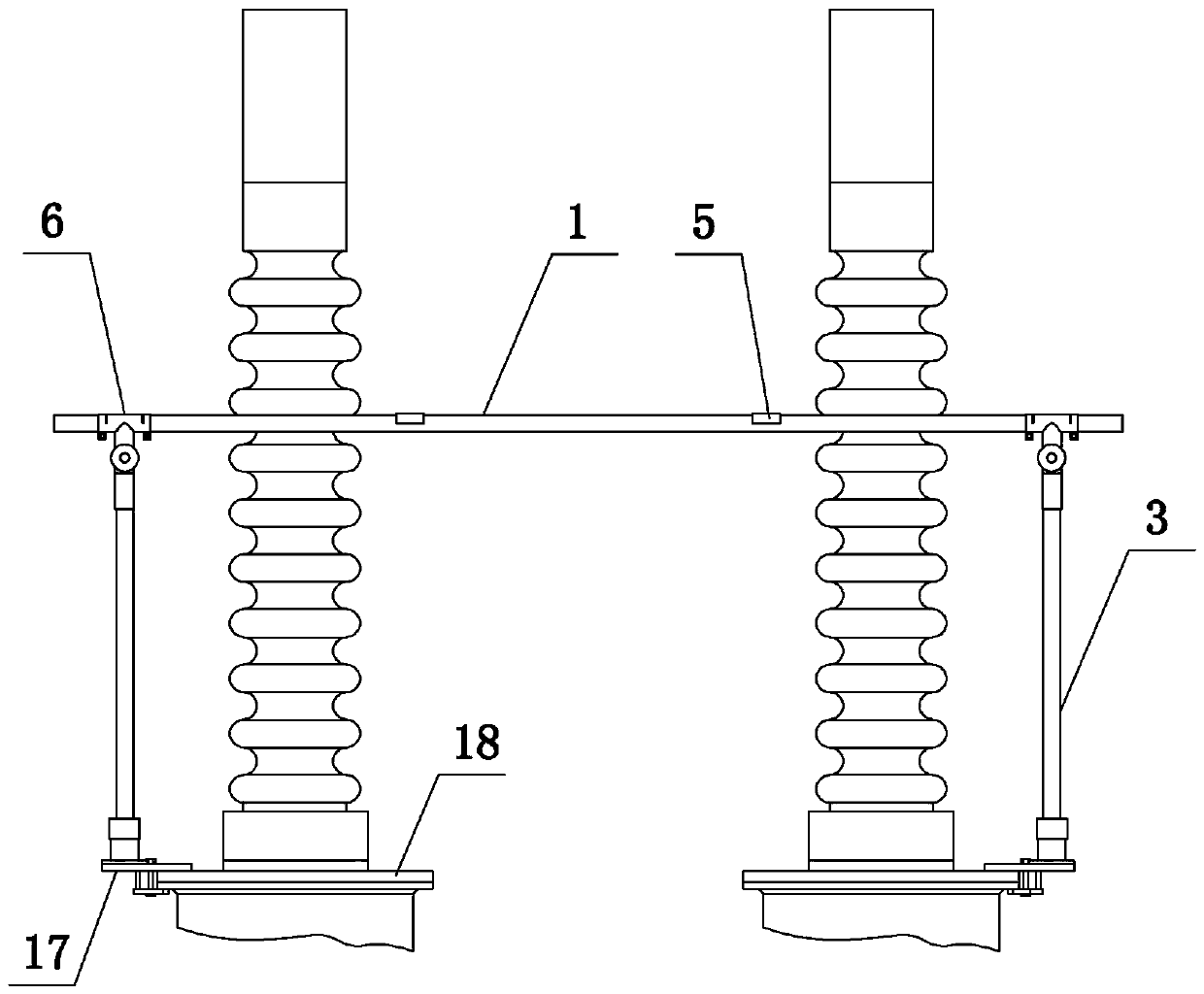

[0056] The invention discloses a 1000kV ultra-high voltage transformer low-voltage lead wire disassembly platform, which includes an operation platform and a fixing component.

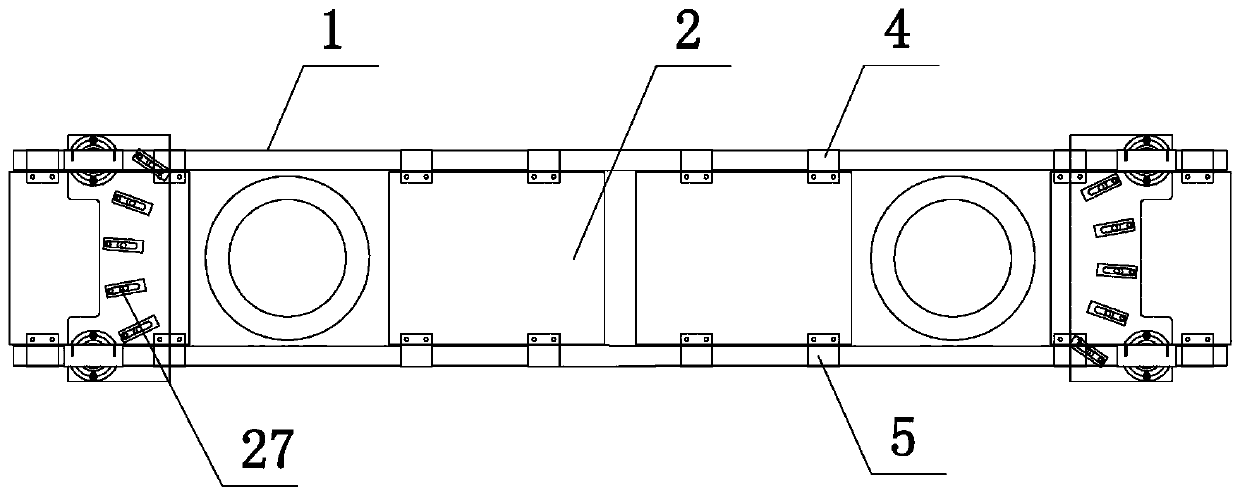

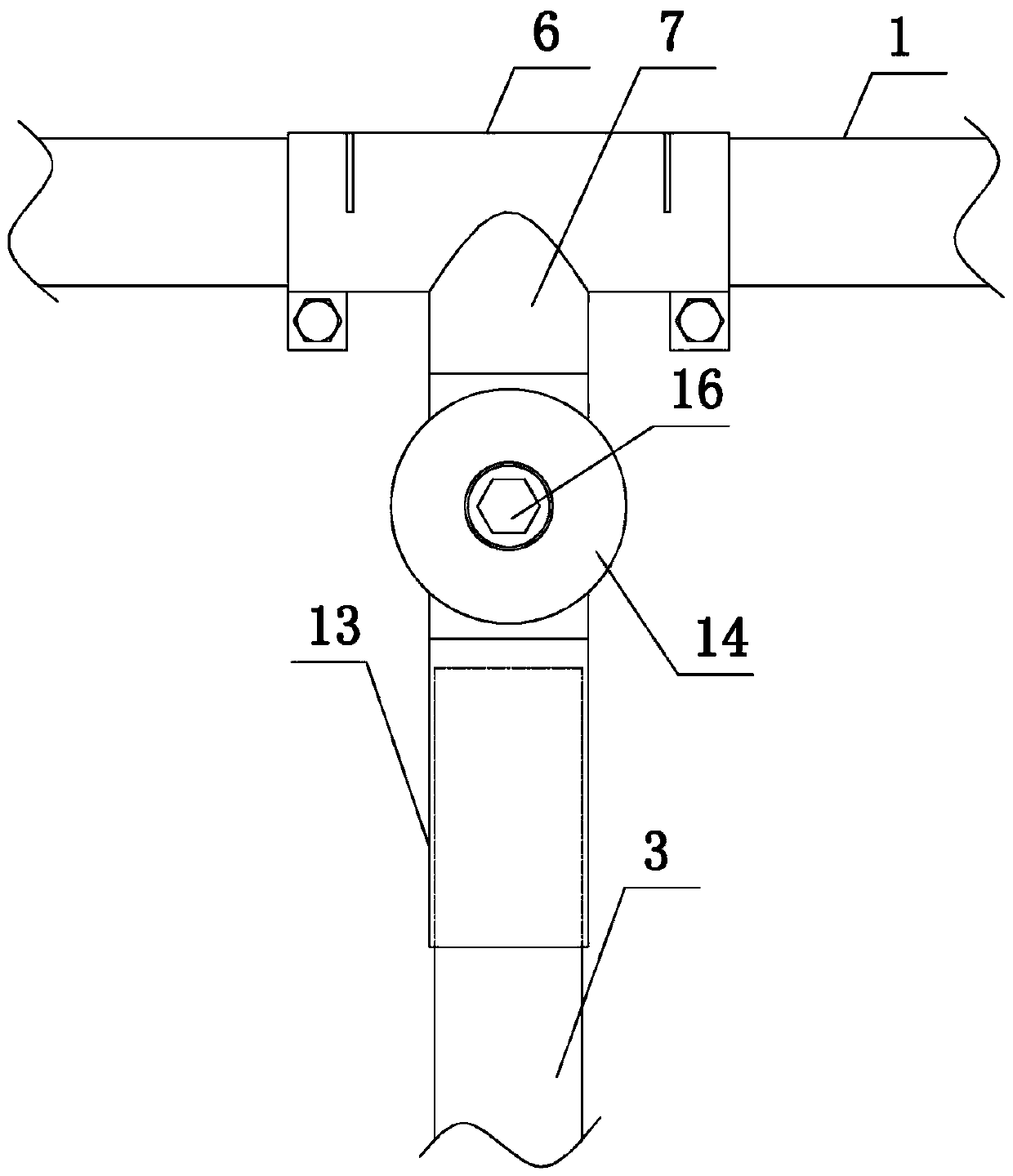

[0057] Such as figure 1 and figure 2 As shown, the work platform includes two horizontal bars 1 arranged in parallel, four foot boards 2 arranged between the two horizontal bars 1 for providing standing space, and two footboards 2 fixed on the two horizontal bars for providing vertical support. The four outriggers 3 on the crossbar 1; among them, the crossbar 1 and the outriggers 3 are made of epoxy resin fiberglass tubes, the footboard 2 is made of 3mm thick patterned aluminum plate, and the upper and lower ends of the footboard 2 are provided with silicon Rubber protective pad, one end of the pedal 2 is provided with a pedal sleeve 4 socketed with the crossbar 1, and the other end is provided with an arc-shaped clamping plate 5 clamped with the cross-bar 1, and the arc of the arc-shaped clamping pl...

Embodiment 2

[0062] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as Figure 10 and 11 As shown, the crossbar 1 is a detachable structure, including a first rod body 28 and a second rod body 29, one end of the first rod body 28 is connected with a third connecting plate 30 through a first sleeve, and the third connecting plate 30 is connected to the first The sleeve is integrally formed, and the end surface of the third connecting plate 30 is provided with a through hole and four slots 9 evenly arranged around the through hole in the circumferential direction. One end of the second rod body 29 is provided with a fourth connecting plate 31 through the second sleeve. The four connecting plates 31 are integrally formed with the second sleeve, the fourth connecting plate 31 is provided with a through hole and four card protrusions 15 that are uniformly arranged around the through hole in the circumferential direction and match the card groov...

Embodiment 3

[0064] The structure of this embodiment is basically the same as that of Embodiment 1, the difference is: as Figure 12 As shown, two first clamping assemblies can be set on each transformer rising seat flange 18, and the first clamping assembly is positioned at the inner side of the two porcelain bottles; as Figure 13 As shown, two first clamping assemblies can also be arranged on the inner and outer sides of the porcelain bottle, that is, eight first clamping assemblies and eight legs 3 can be used together (the four on the front side are shown in the figure), stable Stronger.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com