Fragrance gel with slow release effect and preparation method and application thereof in cigarettes

A gel and fragrance technology, which is applied in the field of cigarette flavors and fragrances, can solve the problems of shortening product shelf life, restricting the application of fragrances, and short retention time, so as to ensure controllability and uniformity, prolong fragrance retention time, and long-lasting fragrance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of fragrance gel with slow release effect provided by embodiment 1, its preparation process is as follows:

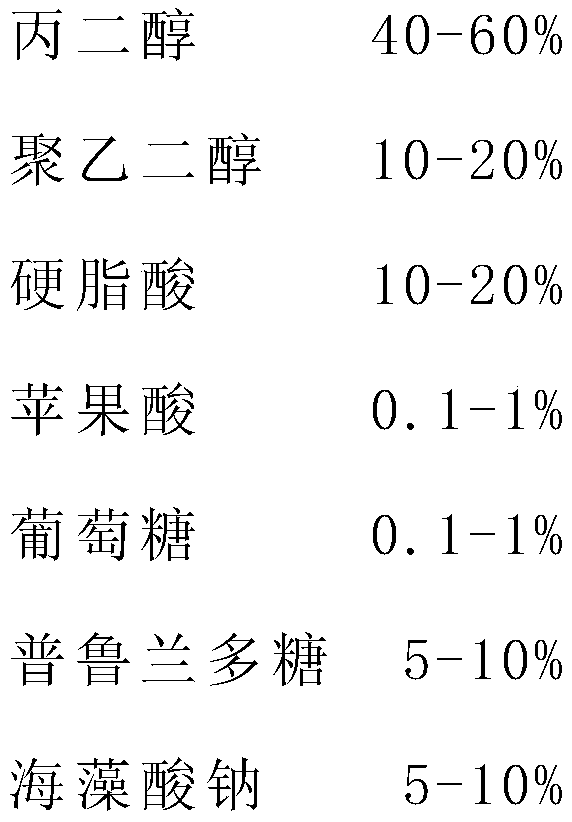

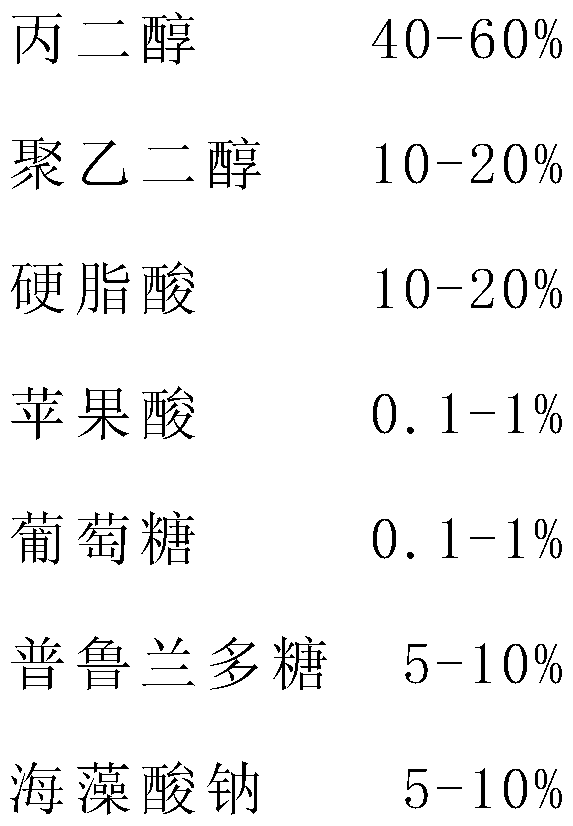

[0031] (1) After weighing the raw materials according to a certain formula ratio, put them into a heating tank with a stirring device, and dissolve them while stirring under the condition of 50°C. The treatment time is 5 hours, and the gel composite material is obtained after the dissolution treatment; The ratio of raw materials is: 60% of propylene glycol, 10% of polyethylene glycol, 10% of stearic acid, 0.5% of malic acid, 0.5% of glucose, 9% of pullulan and 10% of sodium alginate.

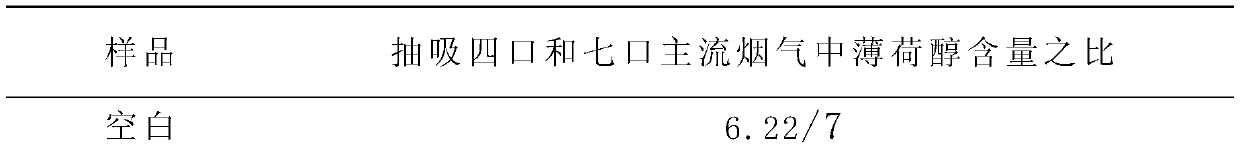

[0032] (2) Add 25% peppermint essence to the gel composite material in step (1), the solvent of the peppermint essence is propylene glycol, and stir and mix to obtain the peppermint flavor gel with slow-release effect.

Embodiment 2

[0033] A kind of fragrance gel with sustained release effect provided by embodiment 2, its preparation process is as follows:

[0034] (1) After weighing the raw materials according to a certain formula ratio, put them into a heating tank with a stirring device, and dissolve them while stirring at 70°C. The treatment time is 3 hours, and the gel composite material is obtained after the dissolution treatment. The ratio of raw materials is: 40% of propylene glycol, 19% of polyethylene glycol, 19% of stearic acid, 1% of malic acid, 1% of glucose, 10% of pullulan and 10% of sodium alginate.

[0035] (2) Add 50% peppermint essence to the gel composite material in step (1), the solvent of the peppermint essence is propylene glycol, stir and mix to obtain the peppermint flavor gel with slow-release effect.

Embodiment 3

[0036] Embodiment 3 provides a kind of fragrance gel with sustained-release effect, and its preparation process is as follows:

[0037] (1) After weighing the raw materials according to a certain formula ratio, put them into a heating tank with a stirring device, and dissolve them while stirring at 60°C. The treatment time is 4 hours, and the gel composite material is obtained after the dissolution treatment. The ratio of raw materials is: 50% of propylene glycol, 16% of polyethylene glycol, 16% of stearic acid, 1% of malic acid, 1% of glucose, 8% of pullulan and 8% of sodium alginate.

[0038] (2) Add 20% peppermint essence to the gel composite material in step (1), the solvent of the peppermint essence is propylene glycol, and stir and mix to obtain the peppermint flavor gel with slow-release effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com