Device for degrading dye wastewater through hydrodynamic cavitation in combination with oxidizing agent

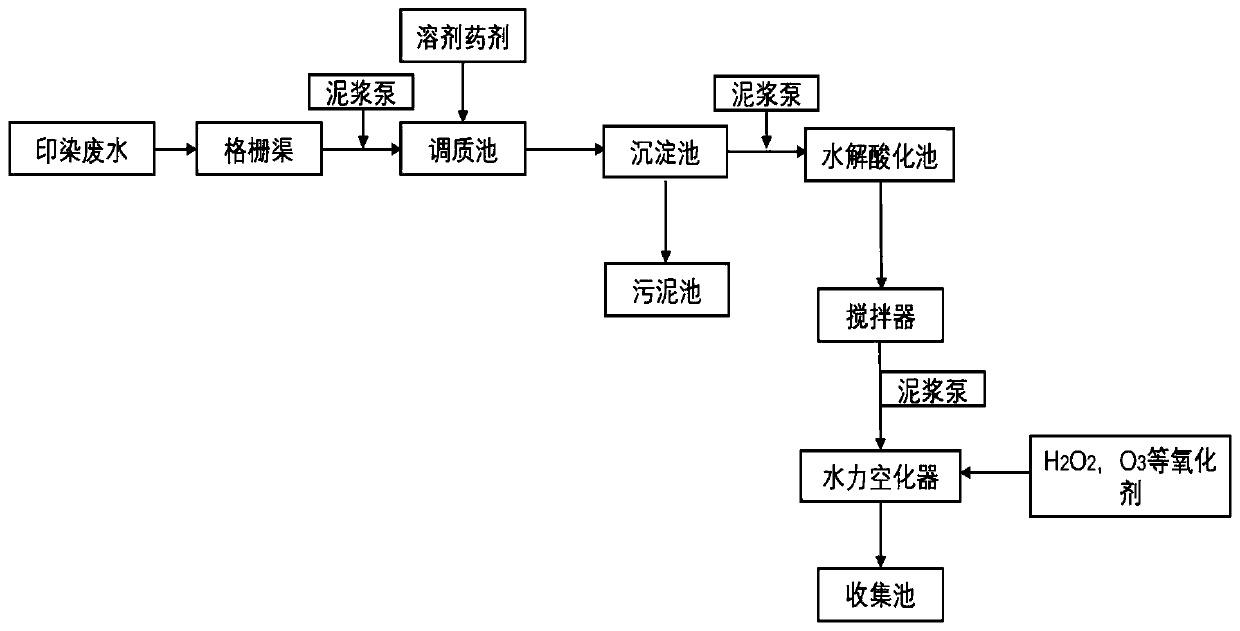

A technology of dye wastewater and hydraulic cavitation, which is applied in the direction of oxidized water/sewage treatment, water pollutants, water/sewage multi-stage treatment, etc., can solve the problems of inability to meet the degradation requirements of dye wastewater, small treatment capacity, and low efficiency. Achieve the effect of improving wastewater treatment efficiency, large treatment capacity, and increasing production volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

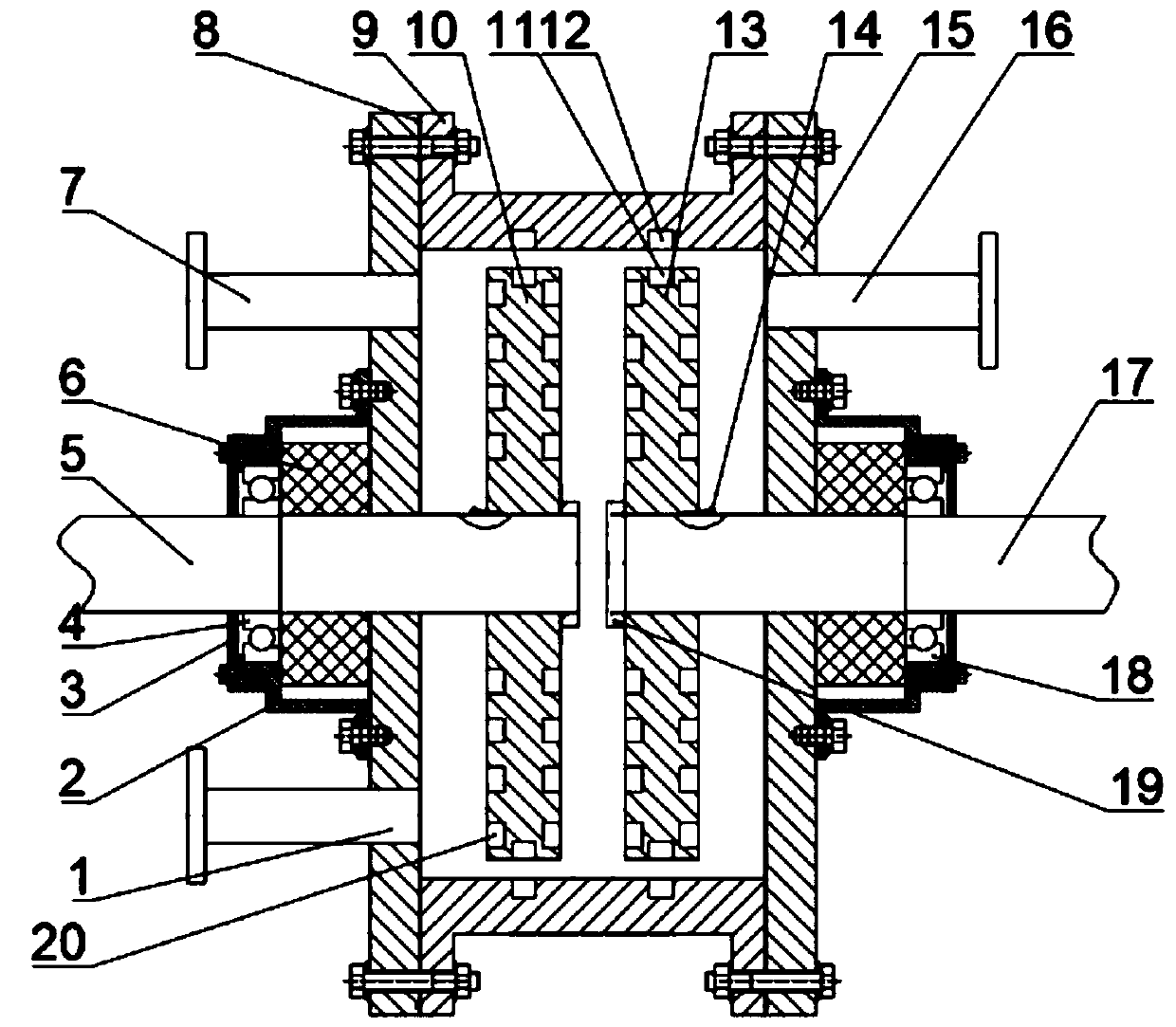

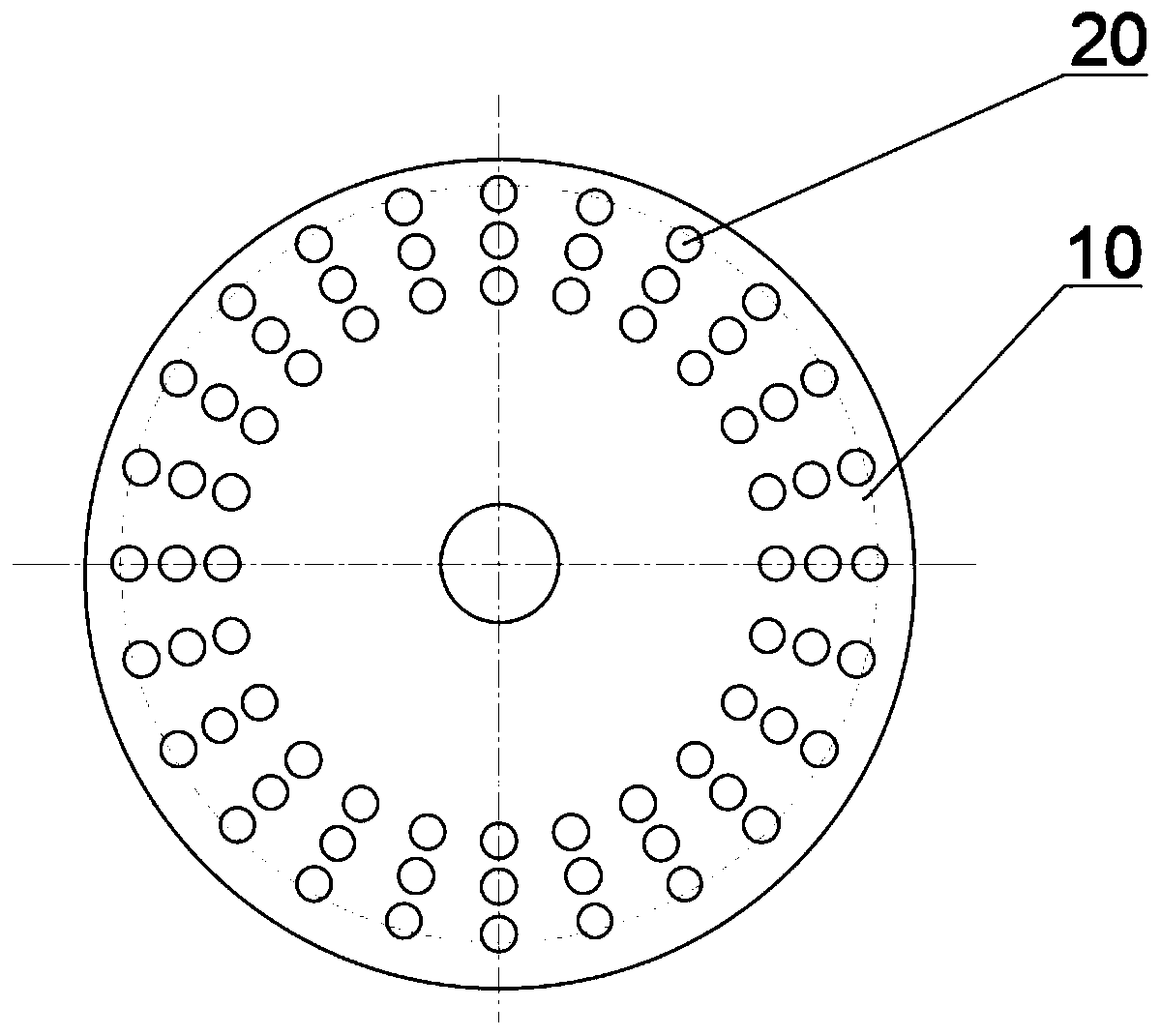

[0033] Such as figure 1 As shown, the device for hydrodynamic cavitation combined with oxidant to degrade dye wastewater of the present invention comprises a stator 9, the two ends of the stator 9 are end caps 15 connected by screws, and the two ends of the end cap 15 are respectively provided with bearing shells 2, bearing shells Angular contact ball bearings 4 are installed in the 2, and the sealing cover 3 is connected to the bearing shell 2, and a sealing ring is arranged at the joint to realize sealing. The stator 9 forms a cavitation chamber through the end covers 15 at both ends thereof. The stator 9 is respectively equipped with a rotating shaft 5 and a rotating shaft 17 through the angular contact ball bearings on both sides. One end of the two rotating shafts is in the cavitation chamber of the stator 9, and the other ends protrude from the left and right end covers of the stator 9 respectively. One end of the rotating shaft 5 in the cavitation cavity is fixedly mou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com