Multi-response fluorescent ink and preparation method

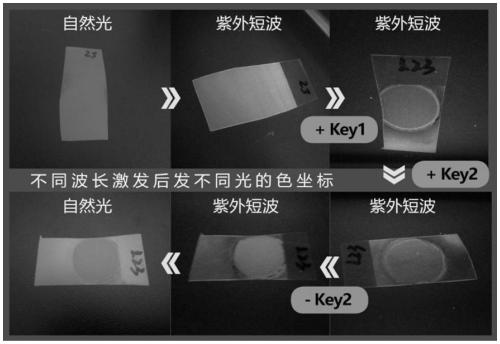

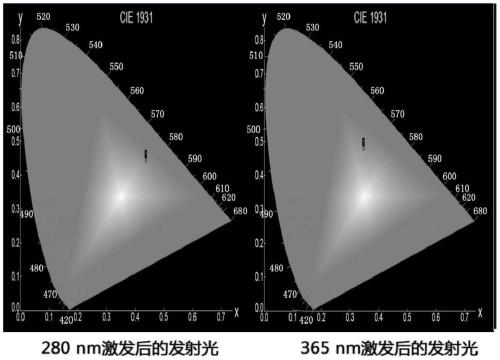

A fluorescent ink, multi-response technology, applied in inks, applications, household appliances, etc., can solve the problem of low anti-counterfeiting level of fluorescent ink, and achieve the effect of complexity and concealment, high anti-counterfeiting level, and improving anti-counterfeiting level.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

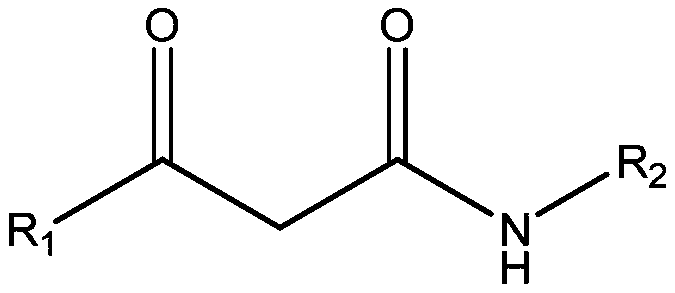

[0033] The fluorescent ink of the embodiment of the present invention is composed of the following components in parts by weight: 0.38 parts by weight of europium nitrate, 0.37 parts by weight of terbium nitrate, 1.2 parts by weight of N-(pyridin-2-yl)-benzoylacetamide, 38.05 parts by weight of denatured alcohol parts by weight, 30 parts by weight of n-butanol, 29 parts by weight of polymer resin, 1 part by weight of auxiliary agent, the rare earth metal salt is selected from one or both of europium salt and terbium salt, and the organic ligand is β - diketone molecules, the polymer resin is a polyamide resin, the auxiliary agent is a slip agent, and an adhesion enhancer is mixed according to a mass ratio of 1:1.

[0034] The preparation method of the fluorescent ink of the embodiment of the present invention comprises the following steps:

[0035] Step 1: mix denatured alcohol and n-butanol evenly, and configure organic solvent;

[0036] Step 2: Take europium nitrate, terbiu...

Embodiment 2

[0040] The fluorescent ink of the embodiment of the present invention is composed of the following components by weight: 0.76 parts by weight of europium nitrate, 0.74 parts by weight of terbium nitrate, 2.4 parts by weight of N-(quinolin-2-yl)-benzoylacetamide, denatured alcohol 36.10 parts by weight, 30 parts by weight of n-butanol, 29 parts by weight of polymer resin, 1 part by weight of auxiliary agent, the rare earth metal salt is selected from one or both of europium salt and terbium salt, and the organic ligand is β-diketone molecules, the polymer resin is selected from epoxy resin, the auxiliary agent is a slip agent, and an adhesion enhancer is mixed according to a mass ratio of 1:1.

[0041] The preparation method of the fluorescent ink of the embodiment of the present invention comprises the following steps:

[0042] Step 1: mix denatured alcohol and n-butanol evenly, and configure organic solvent;

[0043] Step 2: Take europium nitrate, terbium nitrate, and N-(pyr...

Embodiment 3

[0047] The fluorescent ink of the embodiment of the present invention is composed of the following components by weight: 1.13 parts by weight of europium nitrate, 0.5-5 parts by weight of 1.12 parts by weight of terbium nitrate, 3.6 parts by weight of N-(indol-2-yl)-benzoylacetamide Parts by weight, 34.15 parts by weight of technical alcohol, 30 parts by weight of n-butanol, 29 parts by weight of polymer resin, 1 part by weight of auxiliary agent, the rare earth metal salt is selected from one or both of europium salt and terbium salt, so The organic ligand is a β-diketone molecule, the polymer resin is selected from vinyl resin, and the auxiliary agent is a slip agent and an adhesion enhancer mixed in a mass ratio of 1:1.

[0048] The preparation method of the fluorescent ink of the embodiment of the present invention comprises the following steps:

[0049] Step 1: mix denatured alcohol and n-butanol evenly, and configure organic solvent;

[0050] Step 2: Take europium nitra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com