Plastering-free construction method for fabricated building

A construction method and plaster-free technology, which is applied in the direction of building structure, construction, and building material processing, can solve problems such as difficult handling, large gaps, and reduced area of wooden formwork, so as to improve construction quality and efficiency, and ensure The quality of building molding and the effect of saving on-site construction workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

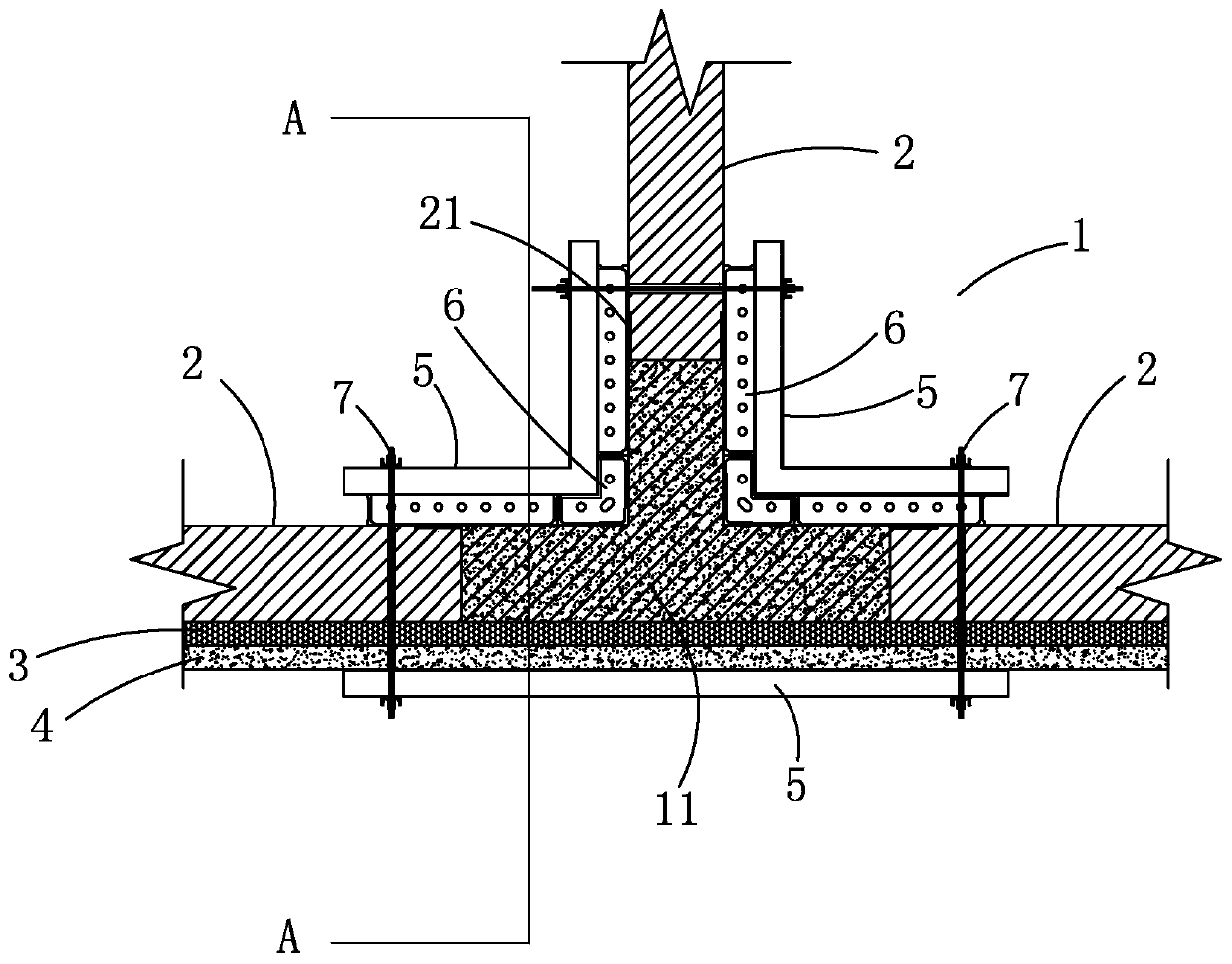

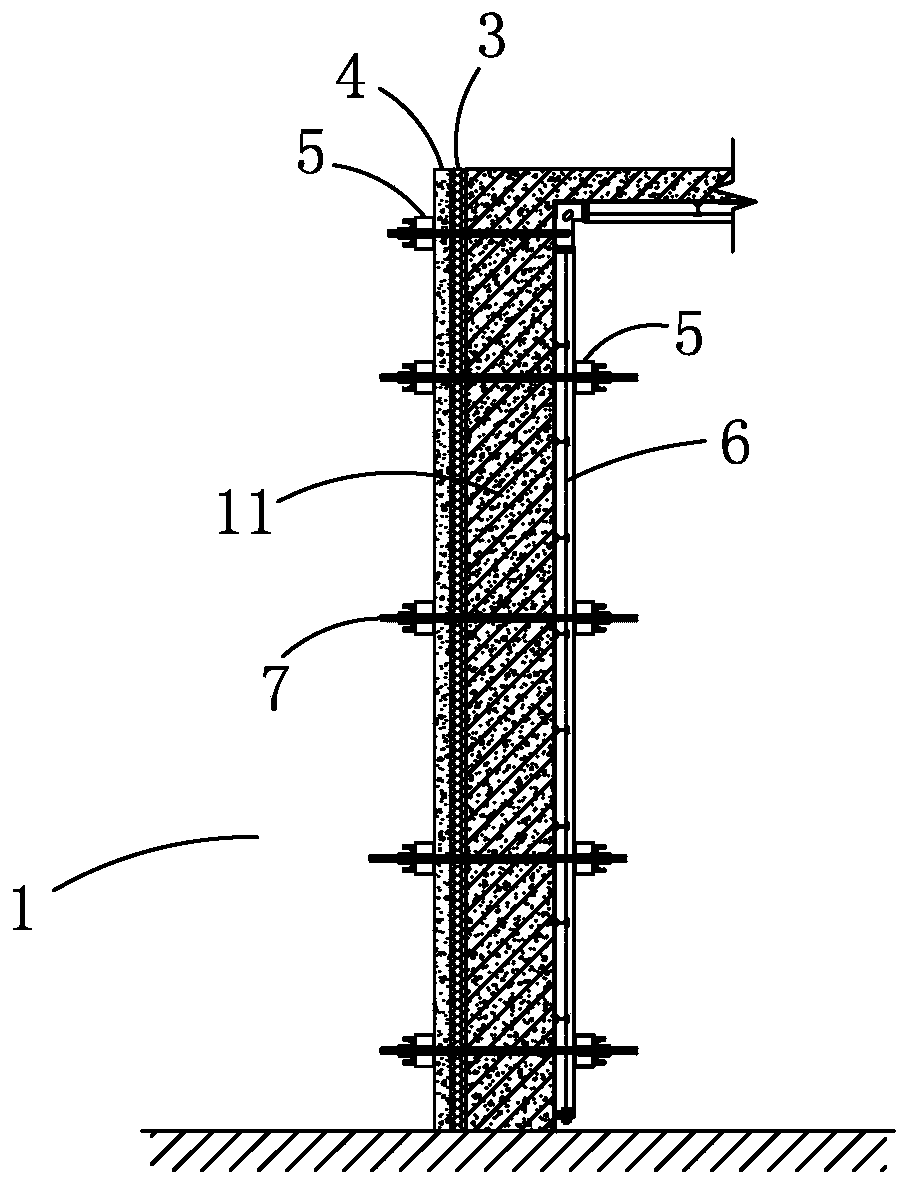

[0057] Embodiment 1, combining Figure 5 to Figure 8 As shown, the PCF board 4 and the PC component 2 are used to connect and cooperate to form an "L"-shaped cast-in-place wall 9, and the "L"-shaped cast-in-place wall 9 includes the upper PC component 2 and the lower PC component 2, so The upper PC component 2 and the lower PC component 2 enclose an "L"-shaped cast-in-place area 91, and operate in the following order, the first step: paste double-sided adhesive tape 21 on the PC component 2 to prevent grout leakage; the second The second step: laying the external wall insulation board 3 on the side and the bottom surface of the "L" type cast-in-place wall 9 respectively; the third step: laying the PCF board 4 on the outer wall insulation board 3; the fourth step: in the " "L" aluminum alloy formwork 6 is installed on the inner side of the L" type cast-in-place area 91; the fifth step: set a reinforced back flute 5 on the back of the PCF board 4, and use a screw rod 7 with a di...

Embodiment 2

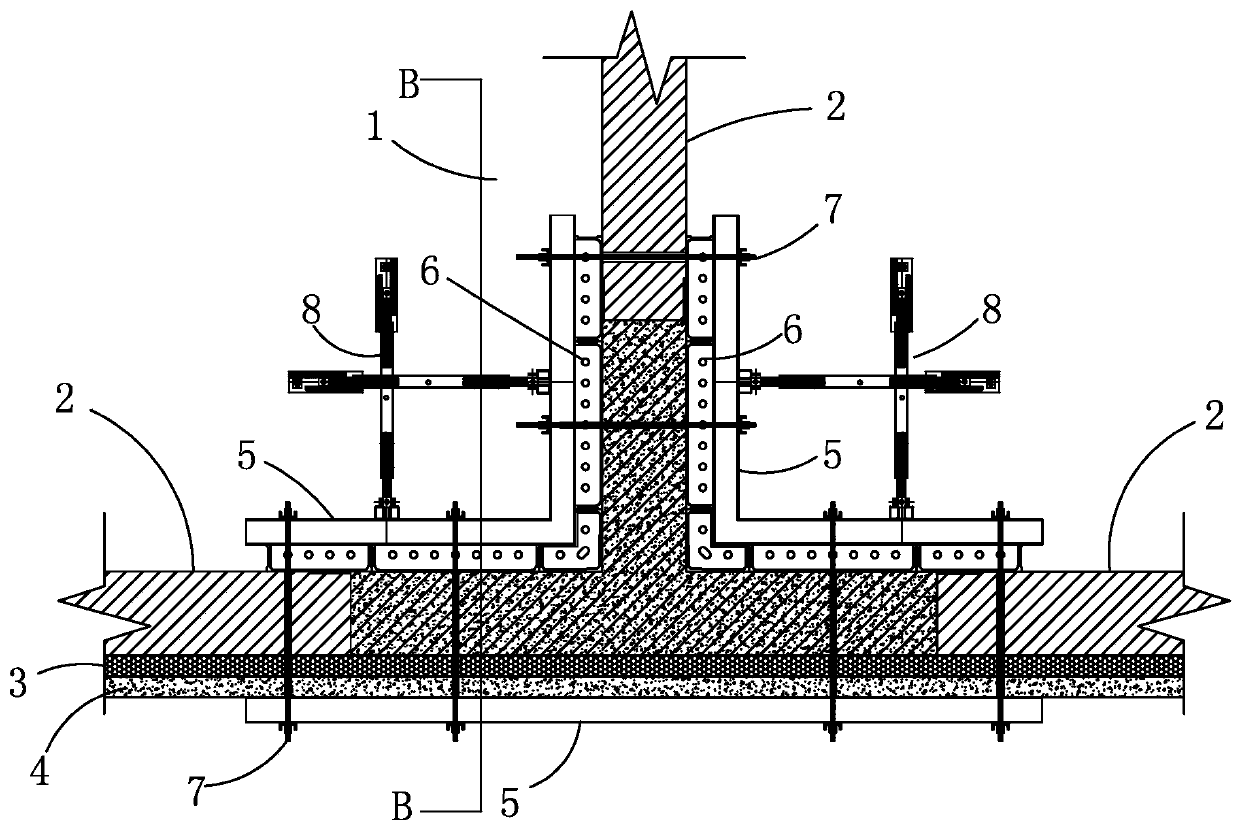

[0058] Example 2, combined with Figure 9 to Figure 12 As shown, the "L" type cast-in-place wall 9 is formed by connecting and cooperating the aluminum alloy template and the PC component 2, and the "L" type cast-in-place wall 9 includes the upper PC component 2 and the lower PC component 2, so The upper PC component 2 and the lower PC component 2 enclose an "L"-shaped cast-in-place area 91, and operate in the following order, the first step: paste double-sided adhesive tape 21 on the PC component 2 to prevent grout leakage; the second Step 2: install "L" type aluminum alloy formwork 6 on the outside of "L" type cast-in-place area 91, install "L" type aluminum alloy formwork 6 inside "L" type cast-in-place area 91; third step: install The back of the "type aluminum alloy formwork 6 is equipped with a reinforced back corrugated 5, and the screw rod 7 with a diameter of 18 mm is passed through the reinforced back corrugated to lock the "L" aluminum alloy formwork 6 inside and ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com