Eddy imaging based metal component defect quantitative detection method and device

A quantitative detection method and technology for metal components, applied in the direction of material magnetic variables, etc., can solve the problems of obvious defect transition area, low defect quantitative detection accuracy, and unsatisfactory imaging results, so as to simplify the processing steps and realize the quantitative detection of defect depth. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to facilitate those skilled in the art to understand the technical content of the present invention, the content of the present invention will be further explained below in conjunction with the accompanying drawings.

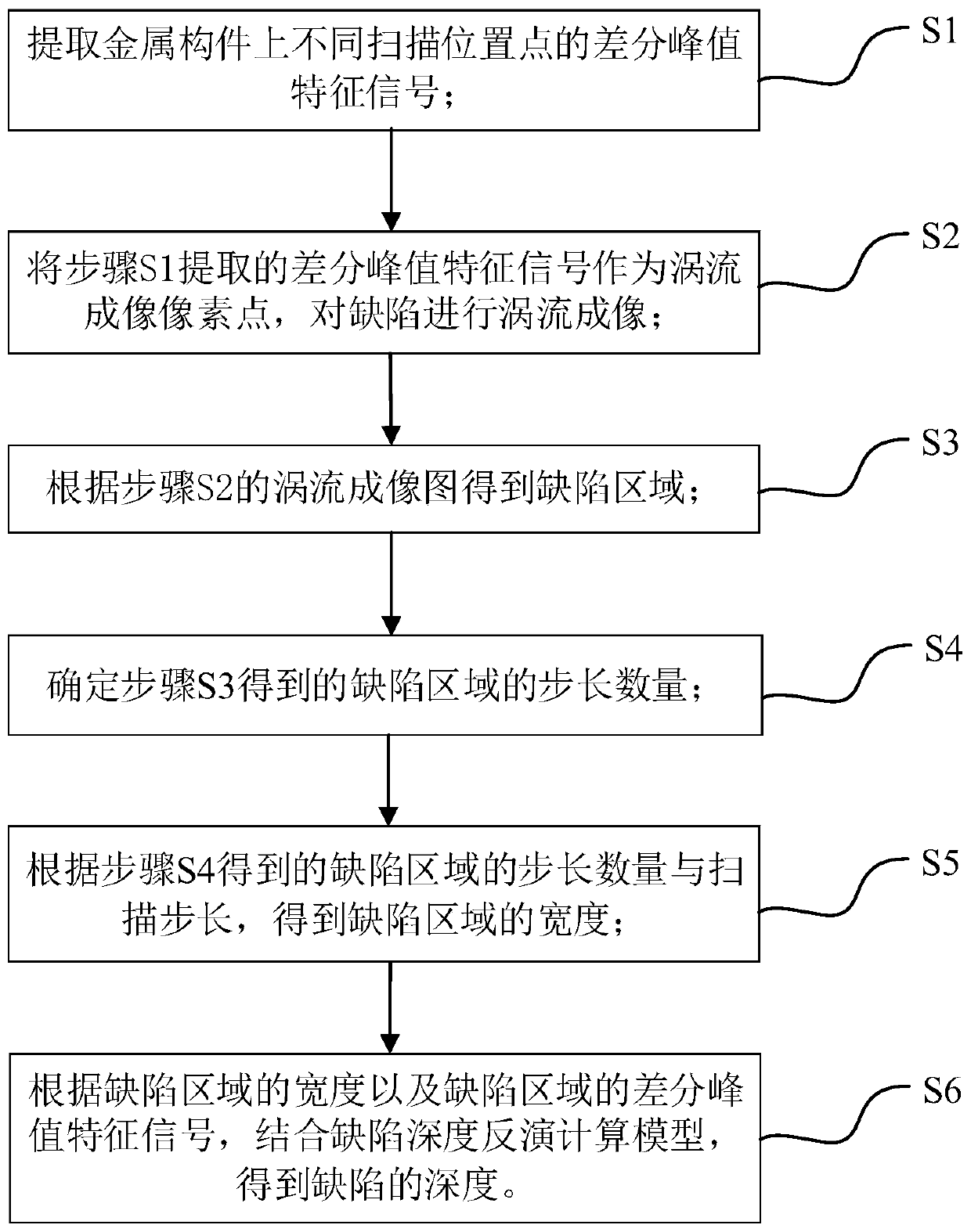

[0031] Such as figure 1 Shown is the scheme flow chart of the present invention, a metal member defect detection method based on eddy current imaging of the present invention, including:

[0032] S1. Extracting the differential peak characteristic signals of different scanning positions on the metal component;

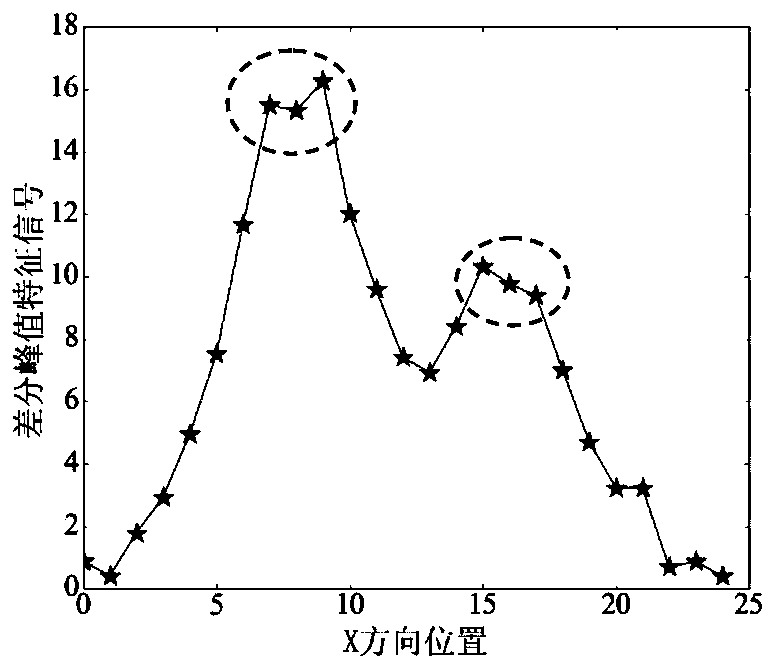

[0033] Based on pulsed eddy current detection technology, the differential peak characteristic signals on metal components at different scanning positions are extracted, that is, the maximum value extracted by differential processing between the magnetic field detection signal at each position point and the non-defective reference signal. The probe of the detection system device is placed on the non-defective area of the test piece to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com