A kind of heavy distillate oil hydrogenation treatment catalyst and its application

A heavy distillate oil, hydrotreating technology, applied in physical/chemical process catalysts, hydrocarbon oil cracking, petroleum industry, etc., can solve problems such as low liquid yield, achieve improved interaction, reduce carbon deposition, and satisfy properties required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

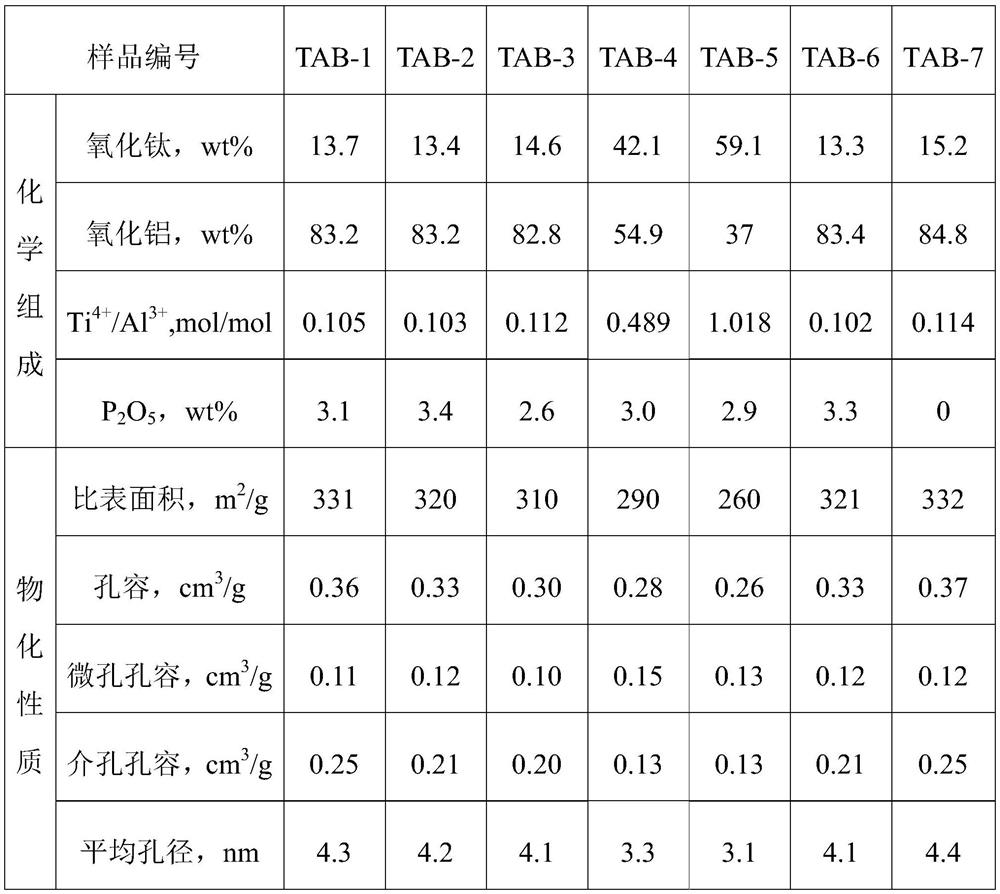

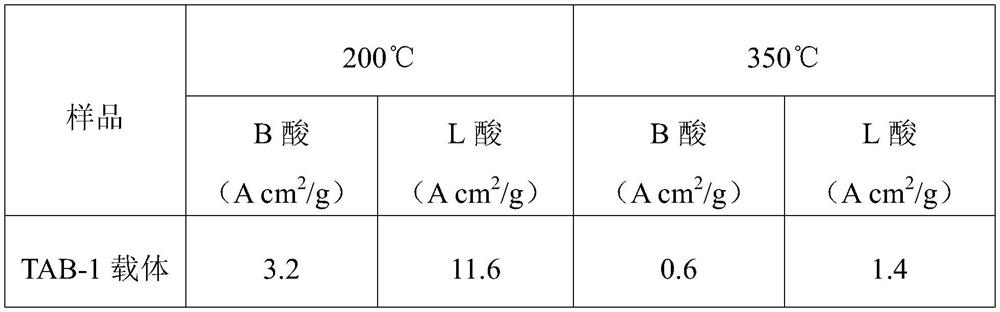

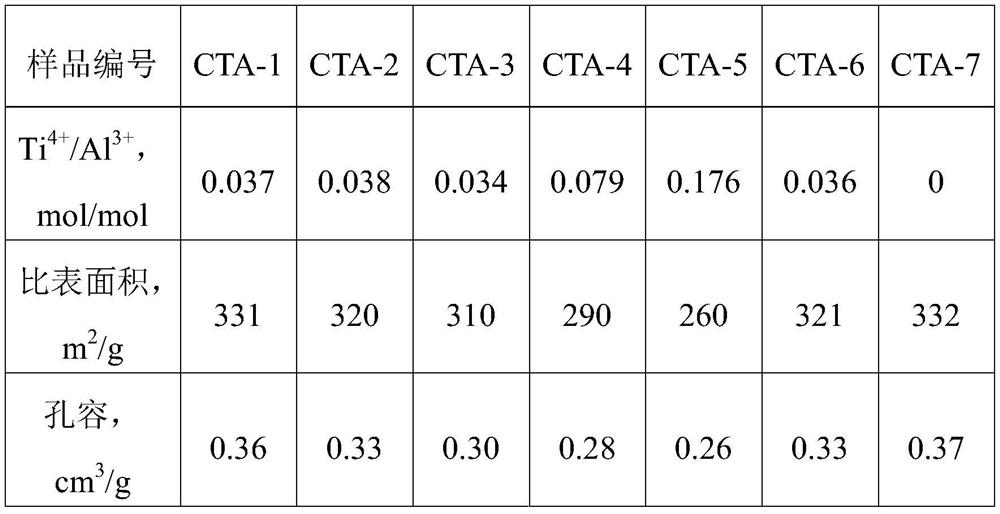

[0033] The invention provides a kind of mesoporous TiO suitable for processing petroleum heavy distillates 2 -Al 2 o 3 , alumina as a carrier material for hydrotreating catalysts, and provide the mesoporous TiO 2 -Al 2 o 3 method of preparation.

[0034] The present invention is characterized in that the mesoporous alumina is synthesized through template agent guidance, and at the same time, titania is introduced into the mesoporous alumina carrier. Mesoporous TiO 2 -Al 2 o 3 Precursors and alumina are used as composite supports. By adjusting the content of each support component, heavy oil hydrotreating catalyst supports with different titanium modifications, different surface areas and suitable acid distribution can be prepared.

[0035] The catalysis provided by the present invention includes an active component and a catalyst carrier, and the active component includes 10% to 40% of a VIB group metal oxide, 1% to 20% of a VIII group metal oxide and / or by weight perc...

Embodiment 1

[0049] Example 1 Template-directed synthesis of mesoporous TiO 2 -Al 2 o 3 TA-1

[0050] (1) 230 gram pseudo-boehmite is joined in 200ml water and stirred and beaten, the nitric acid solution of the 1mol / L of 300ml is added dropwise, obtains the pseudo-boehmite suspension of acidification, the pH of regulating glue solution is 4;

[0051] (2) Add ammonia water to the mixture of step (1) to adjust the pH of the reaction system to be 9, then add 7 g of template agent cetyltrimethylammonium bromide (CTABr), and stir and react in a water bath at 45 ° C for 0.5 h , template agent: A1 3+ The molar ratio is 0.006;

[0052] (3) Add 20 g of ethanol to the mixture obtained in step (2), react for 0.5 h, then add 200 g of butyl titanate, react for 0.5 h, and then transfer to a crystallization tank for aging for 15 h.

[0053] (4) Suction filter the mixture obtained in step (3), and then dry the filter cake at 120°C for 4 hours to obtain mesoporous TiO 2 -Al 2 o 3 Precursor.

Embodiment 2

[0054] Example 2 Template-directed synthesis of mesoporous TiO 2 -Al 2 o 3 TA-2

[0055] (1) 300 grams of pseudo-boehmite are added into 200ml of water and stirred for beating, and the nitric acid solution of 1 mol / L of 300ml is added dropwise to obtain acidified pseudo-boehmite suspension, and the pH of the glue solution is adjusted to be 4 ;

[0056] (2) Add ammonia water to the mixture of step (1) to adjust the pH of the reaction system to be 9, then add 10 g of template agent cetyltrimethylammonium chloride (CTACl), and stir the reaction in a water bath at 40-50°C 0.5h, templating agent: A1 3+ The molar ratio is 0.0067;

[0057] (3) Add 20 g of ethanol to the mixture obtained in step (2), react for 0.5 h, then add 200 g of butyl titanate, react for 0.5 h, and then transfer to a crystallization tank for aging for 15 h.

[0058] (4) Suction filter the mixture obtained in step (3), and then dry the filter cake at 120°C for 4 hours to obtain mesoporous TiO 2 -Al 2 o 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com