Quantitative cement mortar paste mixer for building

A technology for slurry mixer and construction, which is applied to cement mixing devices, clay preparation devices, chemical instruments and methods, etc., can solve problems such as waste, lack of control of mixing speed, and inability to carry out quantitative cement mixing, etc., so as to improve work efficiency. Efficiency, the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

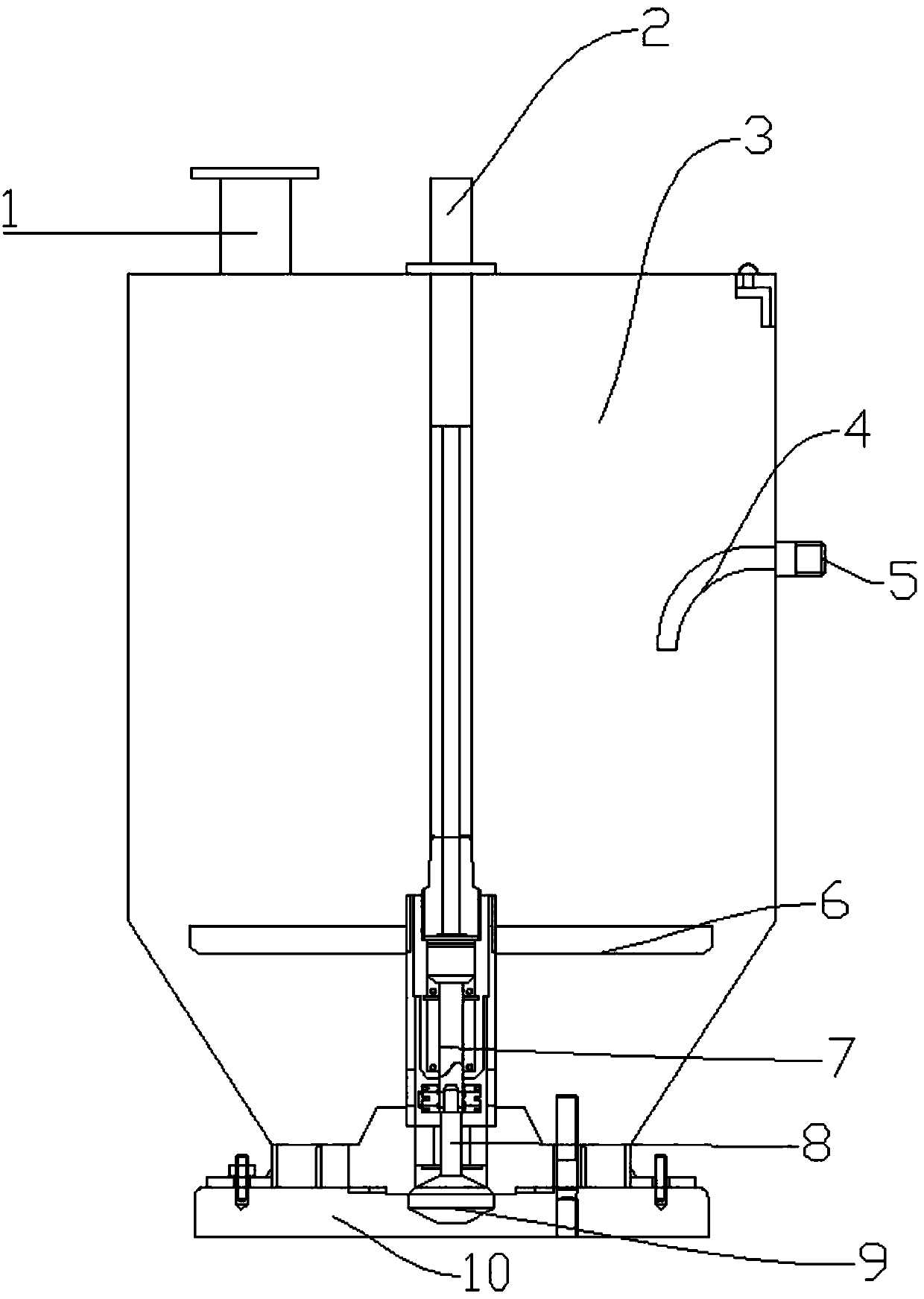

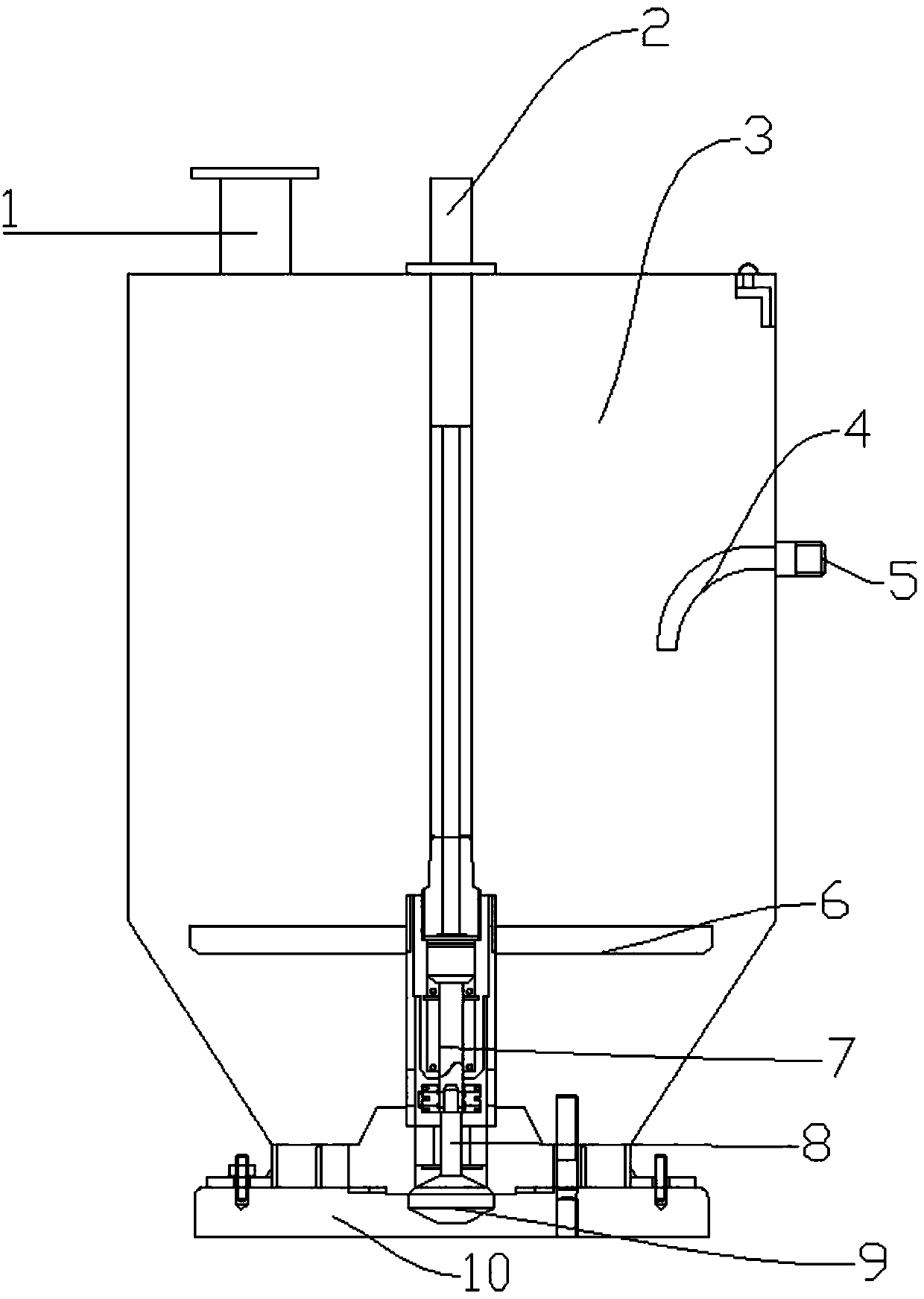

[0015] Such as figure 1 As shown, a quantitative cement slurry mixer for construction includes a cement raw material injection pipe 1, a water level gauge 4, a worm 7 and a fixed base 10. The cement raw material injection pipe 1 is installed on the top of the mixing chamber 3, and the end of the water level gauge 4 is set There is a water level indicator 5, the top of the worm 7 is connected with the water injection pipe 2, two slurry mixing rods 6 are installed on the water injection pipe 2, a motor 8 is installed under the worm 7, and a speed controller is installed between the fixed base 10 and the motor 8 9.

[0016] In the above structure, the rotational speed of the rotational speed controller 9 is set according to the requirements, the raw materials to be mixed are injected into the mixing chamber 3 from the cement raw material injection pipe 1, and water is injecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com