Wear-resistant composite steel plate and manufacturing method thereof

A composite steel plate and manufacturing method technology, applied in the direction of chemical instruments and methods, laminated, layered products, etc., can solve the problems of grate seam sticking, dead mill output, easy cracking, poor quality of ingots, etc., to avoid toughness The effect of low density, reduced material consumption, and reduced material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

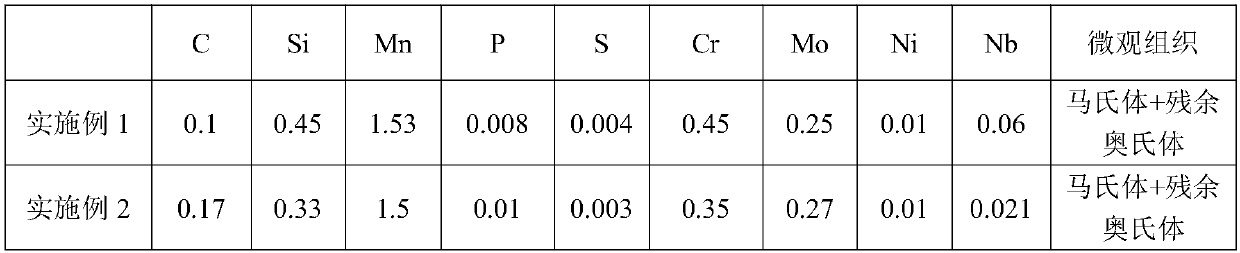

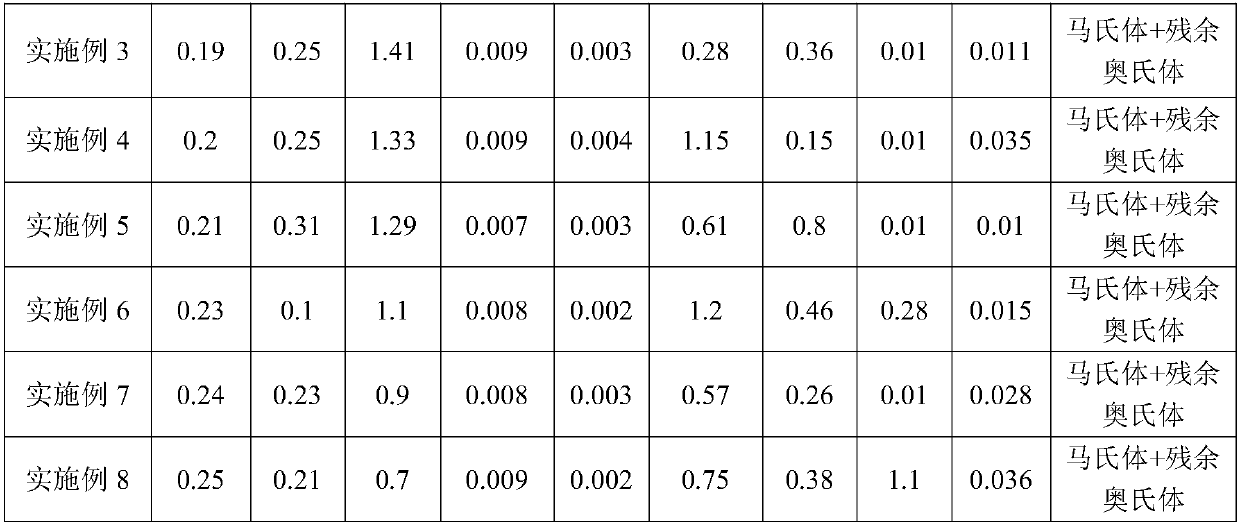

[0068] Table 1-1 and Table 1-2 list the mass percentage distribution ratio of each chemical element in the carbon steel layer of the wear-resistant composite steel plate of Examples 1-8.

[0069] Table 1-1. (wt%, the balance is Fe and other impurity elements except S, P, N, H and O)

[0070]

[0071]

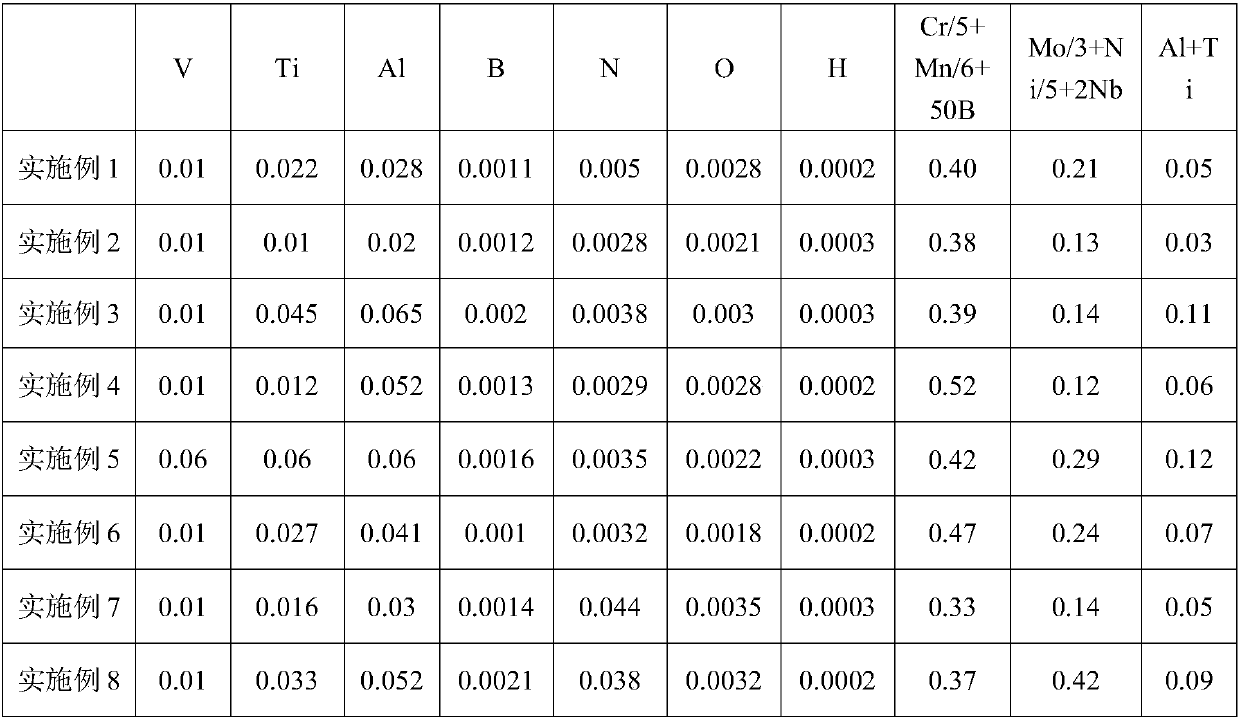

[0072] Table 1-2. (wt%, the balance is Fe and other impurity elements except S, P, N, H and O)

[0073]

[0074] Table 2 lists the mass percentage distribution of each chemical element in the high manganese steel layer of the wear-resistant composite steel plate of Examples 1-8.

[0075] Table 2. (wt%, the balance is Fe and other impurity elements except S and P)

[0076]

[0077]

[0078] The wear-resistant composite steel plate of embodiment 1-8 adopts following steps to make:

[0079] (1) Smelting according to Table 1-1, Table 1-2 and Table 2 to obtain carbon steel layer slabs and high manganese steel layer slabs;

[0080] (2) Blank assembly;

[0081] (3) H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com