Preparation method of MnZn ferrite material with ultralow high-temperature power loss

A ferrite material, power loss technology, applied in the field of crushing and sintering process, can solve the problem of high power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

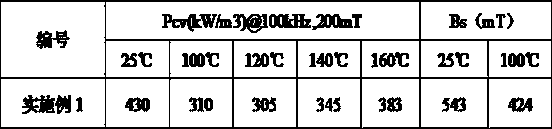

Embodiment 1

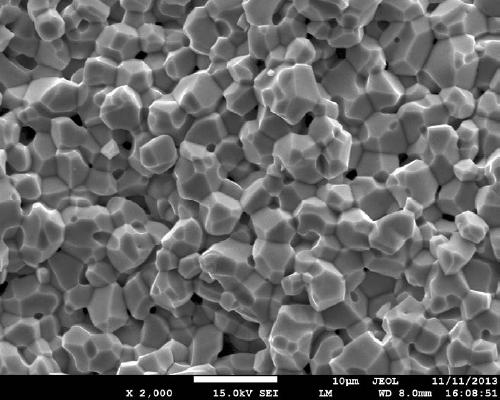

[0030] Utilize the method provided by the present invention to prepare ultra-low high temperature power loss MnZn ferrite ring magnetic core, the preparation steps are as follows:

[0031] (1) with high purity Fe 2 o 3 , MnCO 3 and ZnO as raw materials, according to Fe2O3 is 53.10mol%, ZnO is 9.40mol%, and MnO is the balance; according to the total weight of the main component, the content of each component of the additive auxiliary component is: CaCO 3 0.05%, Nb 2 o 5 0.03%, Co 2 o 3 0.4%, ZrO 2 0.02%, KHCO 3The metering of the component raw materials is carried out at 0.010%. First to Fe 2 o 3 , MnCO 3 Raw materials such as ZnO and ZnO are firstly ground separately until the average particle size reaches 0.8-1.2 μm, and then a uniform mixed powder is obtained through a 0.5-hour ball milling process. Furthermore, the mixed powder was pressed into a block at 50 MPa, and pre-calcined in the air, the pre-calcination temperature was 850°C, and the synthesis time was 2...

Embodiment 2

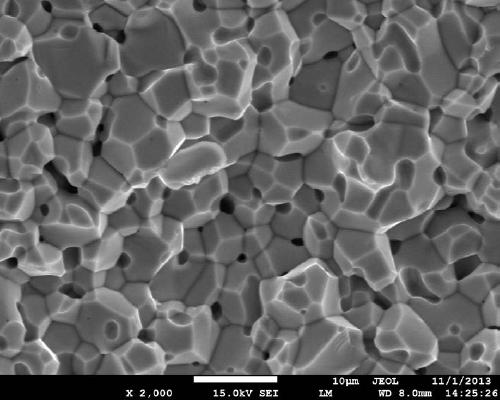

[0043] Utilize the method provided by the present invention to prepare ultra-low high temperature power loss MnZn ferrite ring magnetic core, the preparation steps are as follows:

[0044] (1) with high purity Fe 2 o 3 , MnCO 3 and ZnO as raw material, according to Fe 2 o 3 is 53.10mol%, ZnO is 9.40mol%, and MnO is the balance; based on the total weight of the main component, the content of each component of the additive and auxiliary components is: CaCO 3 0.05%, Nb 2 o 5 0.03%, Co 2 o 3 0.4%, ZrO 2 0.02%, KHCO 3 The metering of the component raw materials takes place at 0%. First to Fe 2 o 3 , MnCO 3 Raw materials such as ZnO and ZnO are firstly ground separately until the average particle size reaches 0.8-1.2 μm, and then a uniform mixed powder is obtained through a 0.5-hour ball milling process. Furthermore, the mixed powder was pressed into a block at 50 MPa, and pre-calcined in the air, the pre-calcination temperature was 850°C, and the synthesis time was 2....

Embodiment 3

[0056] Utilize the method provided by the present invention to prepare ultra-low high temperature power loss MnZn ferrite ring magnetic core, the preparation steps are as follows:

[0057] (1) with high purity Fe 2 o 3 , MnCO 3 and ZnO as raw material, according to Fe 2 o 3 is 53.30mol%, ZnO is 9.20mol%, and MnO is the balance; based on the total weight of the main component, the content of each component of the additive and auxiliary components is: CaCO 3 0.05%, Nb 2 o 5 0.03%, Co 2 o 3 0.4%, ZrO 2 0.02%, KHCO 3 The metering of the component raw materials is carried out at 0.010%. First to Fe 2 o 3 , MnCO 3 Raw materials such as ZnO and ZnO are firstly ground separately until the average particle size reaches 0.8-1.2 μm, and then a uniform mixed powder is obtained through a 0.5-hour ball milling process. Furthermore, the mixed powder was pressed into a block at 50 MPa, and pre-calcined in the air, the pre-calcination temperature was 850°C, and the synthesis time...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com