Method for increasing glycosaminoglycan stability of bioprosthetic heart valve

A valve glycosamine and stability technology, applied in the field of biomedical materials and medical devices, can solve the problems of ineffectiveness and low efficiency, and achieve the effects of prolonging service life, improving stability and improving anti-calcification performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

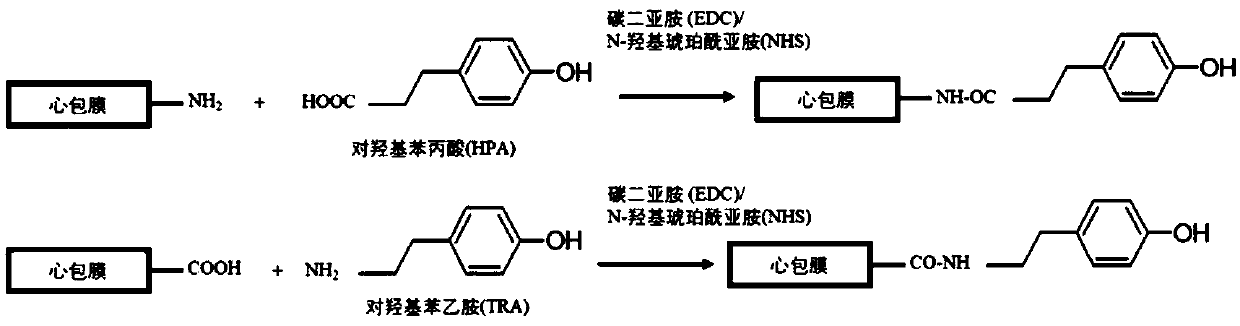

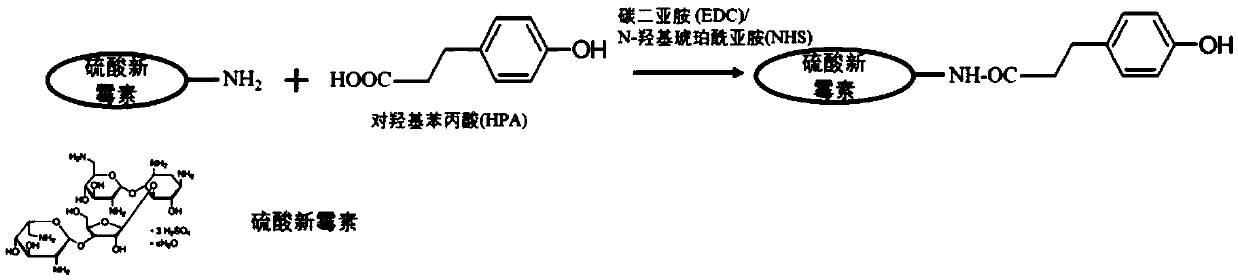

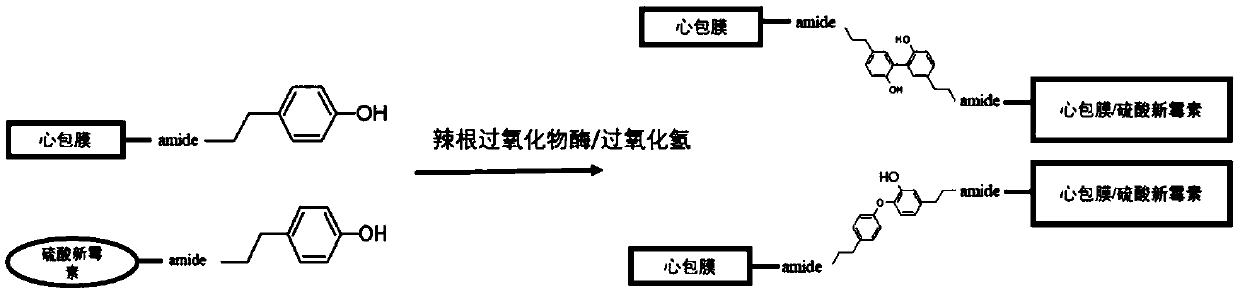

Embodiment 1

[0023] In this embodiment, the freshly collected porcine pericardium was washed with distilled water for 2 hours at 4°C and 100 RPM with shaking. Then soak in 50mM p-hydroxyphenylpropionic acid and 0.2M p-hydroxyphenylethylamine aqueous solution for 4 hours at room temperature. Then soak in 20 mM carbodiimide and 10 mM N-hydroxysuccinimide for 24 hours at room temperature. Simultaneously, p-hydroxyphenylpropionic acid-modified neomycin sulfate was prepared. Add p-hydroxyphenylpropionic acid and neomycin sulfate in an equimolar ratio, add 20mM carbodiimide and 10mM N-hydroxysuccinimide to react at room temperature for 24 hours, then add ethanol to precipitate and dialyze to clean, and prepare hydroxyphenylpropanoid Acid-modified neomycin sulfate. Add 0.4mM p-hydroxyphenylpropionic acid-modified neomycin sulfate to the above-mentioned hydroxyphenylpropionic acid and p-hydroxyphenylethylamine-modified pericardium, and then use 1% horseradish peroxidase and 1% hydrogen peroxide ...

Embodiment 2

[0025] In this embodiment, the freshly collected porcine pericardium was washed with distilled water for 2 hours at 4°C and 100 RPM with shaking. Then soak in 50mM p-hydroxyphenylpropionic acid and 0.2M p-hydroxyphenylethylamine aqueous solution for 4 hours at room temperature. Then soak in 20 mM carbodiimide and 10 mM N-hydroxysuccinimide for 24 hours at room temperature. Simultaneously, p-hydroxyphenylpropionic acid-modified neomycin sulfate was prepared. Add p-hydroxyphenylpropionic acid and neomycin sulfate in an equimolar ratio, add 20mM carbodiimide and 10mM N-hydroxysuccinimide to react at room temperature for 24 hours, then add ethanol to precipitate and dialyze to clean, and prepare hydroxyphenylpropanoid Acid-modified neomycin sulfate. Add 2 mM p-hydroxyphenylpropionic acid-modified neomycin sulfate to the above-mentioned hydroxyphenylpropionic acid and p-hydroxyphenylethylamine-modified pericardium, and then use 1% horseradish peroxidase and 1% hydrogen peroxide a...

Embodiment 3

[0027] In this embodiment, the freshly collected porcine pericardium was washed with distilled water for 2 hours at 4°C and 100 RPM with shaking. Then soak in 50mM p-hydroxyphenylpropionic acid and 0.2M p-hydroxyphenylethylamine aqueous solution for 4 hours at room temperature. Then soak in 20 mM carbodiimide and 10 mM N-hydroxysuccinimide for 24 hours at room temperature. Simultaneously, p-hydroxyphenylpropionic acid-modified neomycin sulfate was prepared. Add p-hydroxyphenylpropionic acid and neomycin sulfate in an equimolar ratio, add 20mM carbodiimide and 10mM N-hydroxysuccinimide and react at room temperature for 24 hours, then add ethanol to precipitate and dialyze to clean, and prepare hydroxyphenylpropanoid Acid-modified neomycin sulfate. Add 10 mM p-hydroxyphenylpropionic acid-modified neomycin sulfate to the above-mentioned hydroxyphenylpropionic acid and p-hydroxyphenylethylamine-modified pericardium, and then use 1% horseradish peroxidase and 1% hydrogen peroxide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com