Rotary engine

A kind of engine, rotary technology, applied in the direction of combustion engine, machine/engine, internal combustion piston engine, etc., can solve the problems of complex structure, loss of heat energy, inability to create basic adjustment parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

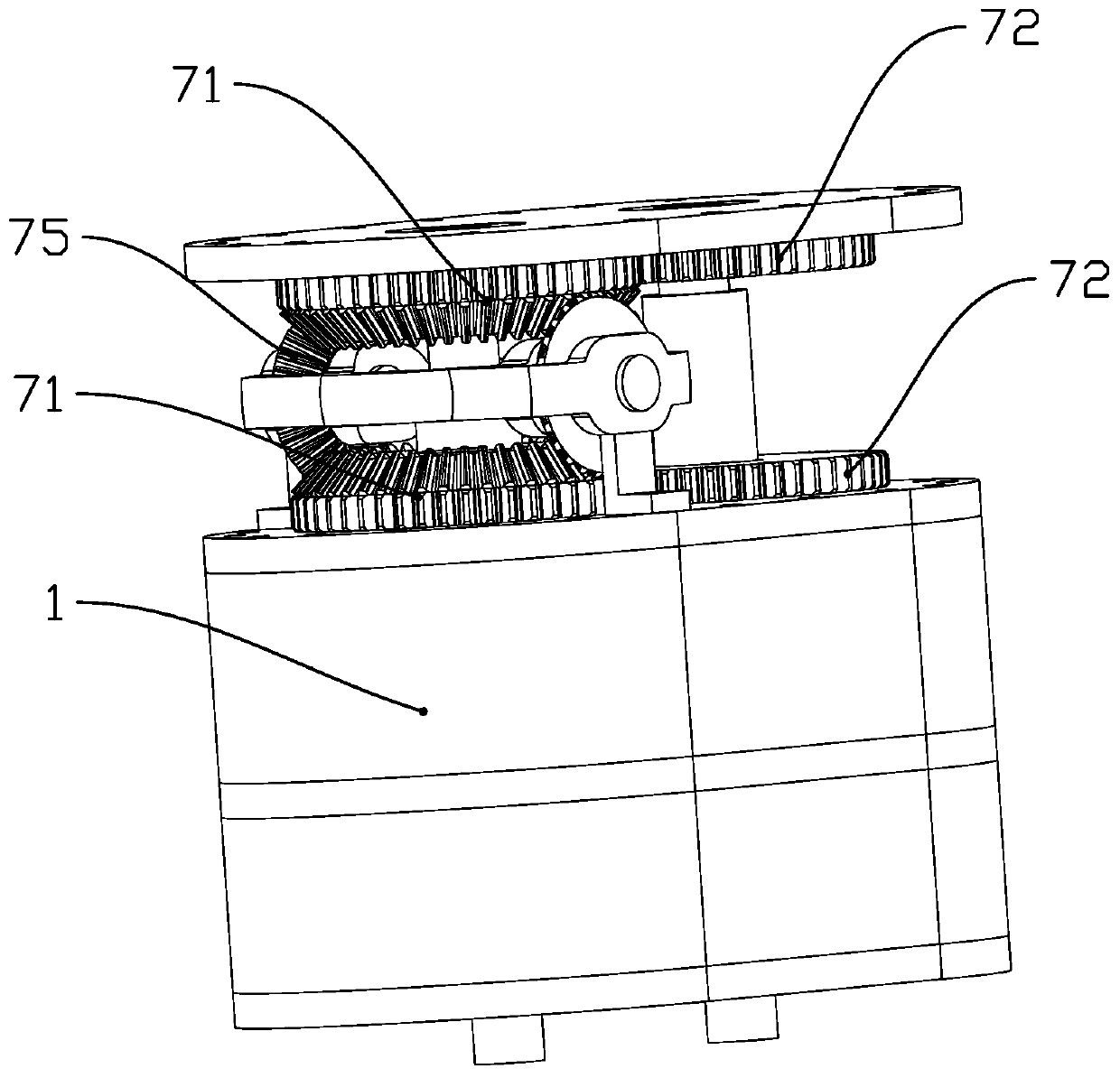

Image

Examples

Embodiment 1

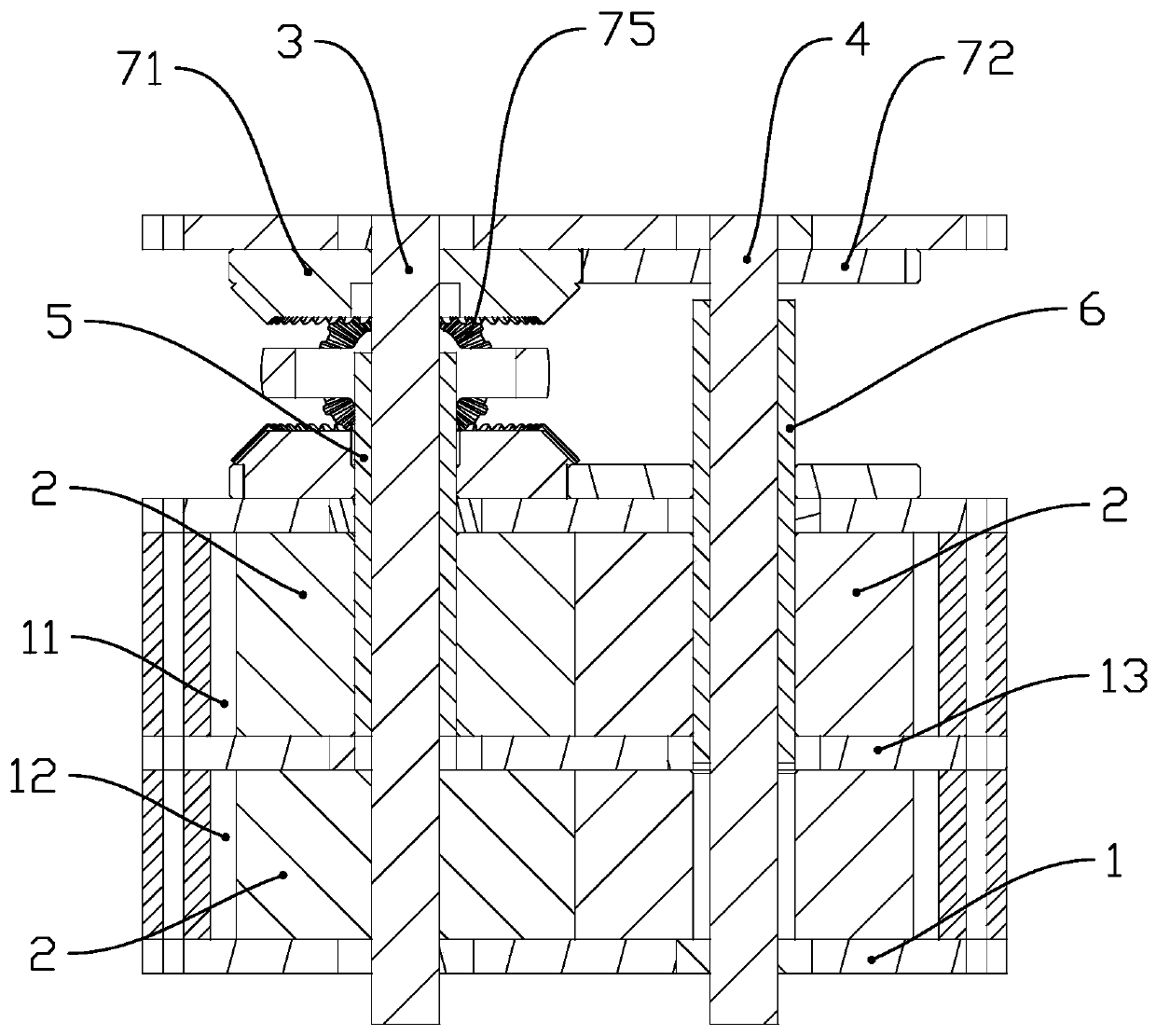

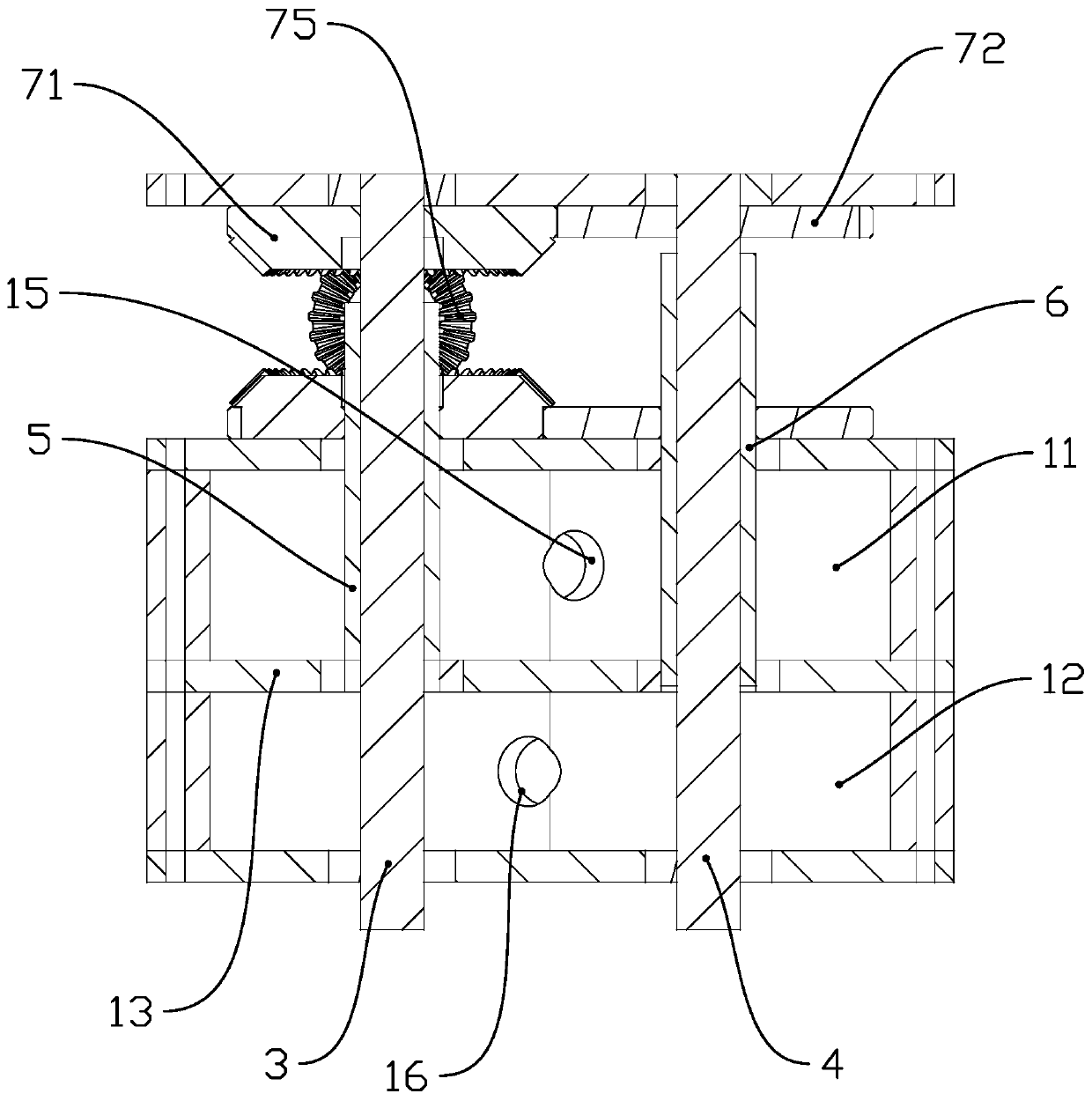

[0056] Each piston 2 is provided with a pair of adjacently arranged grooves 21 and projections 22, an air inlet 15 is provided on the side wall away from the through hole 14 in the upper rotary chamber 11, and an air inlet 15 is provided on the side wall far away from the through hole 14 in the upper rotary chamber 12, and the inner wall of the lower rotary chamber 12 is close to the through hole 14. The side wall of the main body 1 is provided with an oil supply device 17 and an ignition device 18; the side wall of the main body 1 is provided with an oil supply hole 17 connected with the oil supply device and an electrode hole 18 connected with the ignition device, and the electrode hole 18 is connected with the lower rotating chamber. 12 communicates, and the oil supply pipe connecting the oil supply hole 17 and the side wall of the through hole 14 is provided on the partition plate 13; Chamfering, the inner edge of the through hole 14 coincides with the lower edge of the cha...

Embodiment 2

[0058] Each piston 2 is provided with two pairs of grooves 21 and projections 22 at intervals of 180 degrees. When the projection 22 at the front end of the rotation direction in the lower rotating chamber 12 is about to break away from the side wall of the lower rotating chamber 12, the other piston 2 On the dividing plate 13 of the groove 21 matched with the protrusion 22, a through hole 14 connecting the upper rotating chamber 11 and the lower rotating chamber 12 is provided. The two through holes 14 are centrally symmetrical about the dividing plate 13, and the upper rotating chamber 11 and the left and right sides of the lower rotating chamber 12 are all symmetrically provided with an air inlet 15 and an exhaust port 16, and each exhaust port 16 is located on the front side of the corresponding piston 2 in the direction of rotation, and each air inlet 15 are all arranged on the rear side of the corresponding piston 2 in the direction of rotation. The side wall of the main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com