Mechanical rubbing fault diagnosis method based on multi-wavelet kernel-support vector regression (SVR)

A technology of support vector regression and fault diagnosis, which is applied in the testing of mechanical parts, the testing of machine/structural parts, and measuring devices, etc. It can solve problems such as inability to know, large amount of calculation, difficulty, etc., and achieve good signal noise reduction effect, The effect of high prediction accuracy and high signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings.

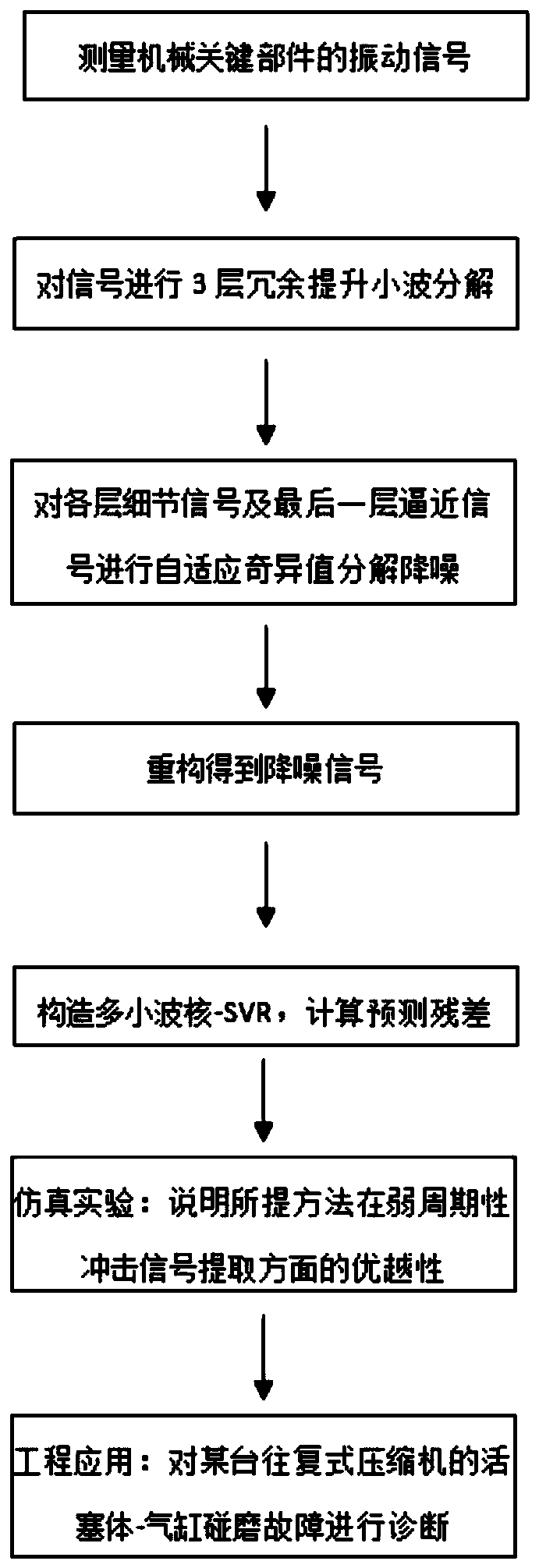

[0068] The present invention is based on the multi-wavelet kernel-support vector regression machine's mechanical grinding fault diagnosis method, refer to figure 1 , including the following steps:

[0069] 1) Obtain vibration signals of key mechanical components. In order to obtain the high-frequency vibration signal generated by mechanical grinding, the sampling frequency is set to 16KHZ, and the sampling length includes at least two vibration cycles.

[0070] 2) Perform 3-layer redundant lifting wavelet decomposition on the signal, perform adaptive singular value decomposition and noise reduction processing on each layer of detail signal and the last layer of approximation signal, and then obtain the final noise-reduced signal through the redundant lifting wavelet reconstruction algorithm. Mechanical vibration signal.

[0071] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com