Semiconductor structures and methods of forming them

A semiconductor and bonding technology, used in semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as poor transistor performance, achieve good interface state, improve service life, and reduce instability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] As mentioned in the background, the performance of the P-type FinFET is poor.

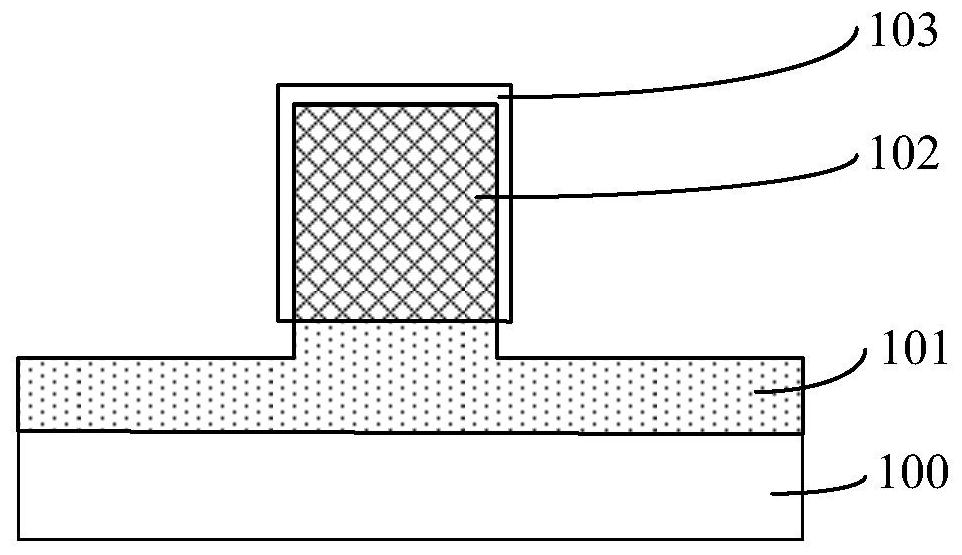

[0033] figure 1 It is a schematic diagram of the structure of a P-type fin field effect transistor.

[0034] Please refer to figure 1 , a substrate 100, the substrate 100 has an insulating layer 101 thereon, and the insulating layer 101 has a fin 102 thereon; an interface layer 103 covering the sidewall and top surface of the fin 102.

[0035] In the above P-type FinFET structure, in order to improve the carrier mobility in the channel region of the P-type FinFET, silicon germanium is used as the material of the fin portion 102 . The carrier mobility is closely related to the concentration of germanium atoms. Specifically, when the atomic percentage concentration of the germanium atoms is less than 25%, the carrier mobility is low, which is not conducive to improving the electrical performance of the P-type fin field effect transistor; on the contrary, when the atomic percentage concentra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com