Power battery liquid cooling device and working method thereof

A power battery and liquid cooling technology, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of low thermal conductivity, heat dissipation, and large heat capacity of phase change materials, etc. Small energy consumption, the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

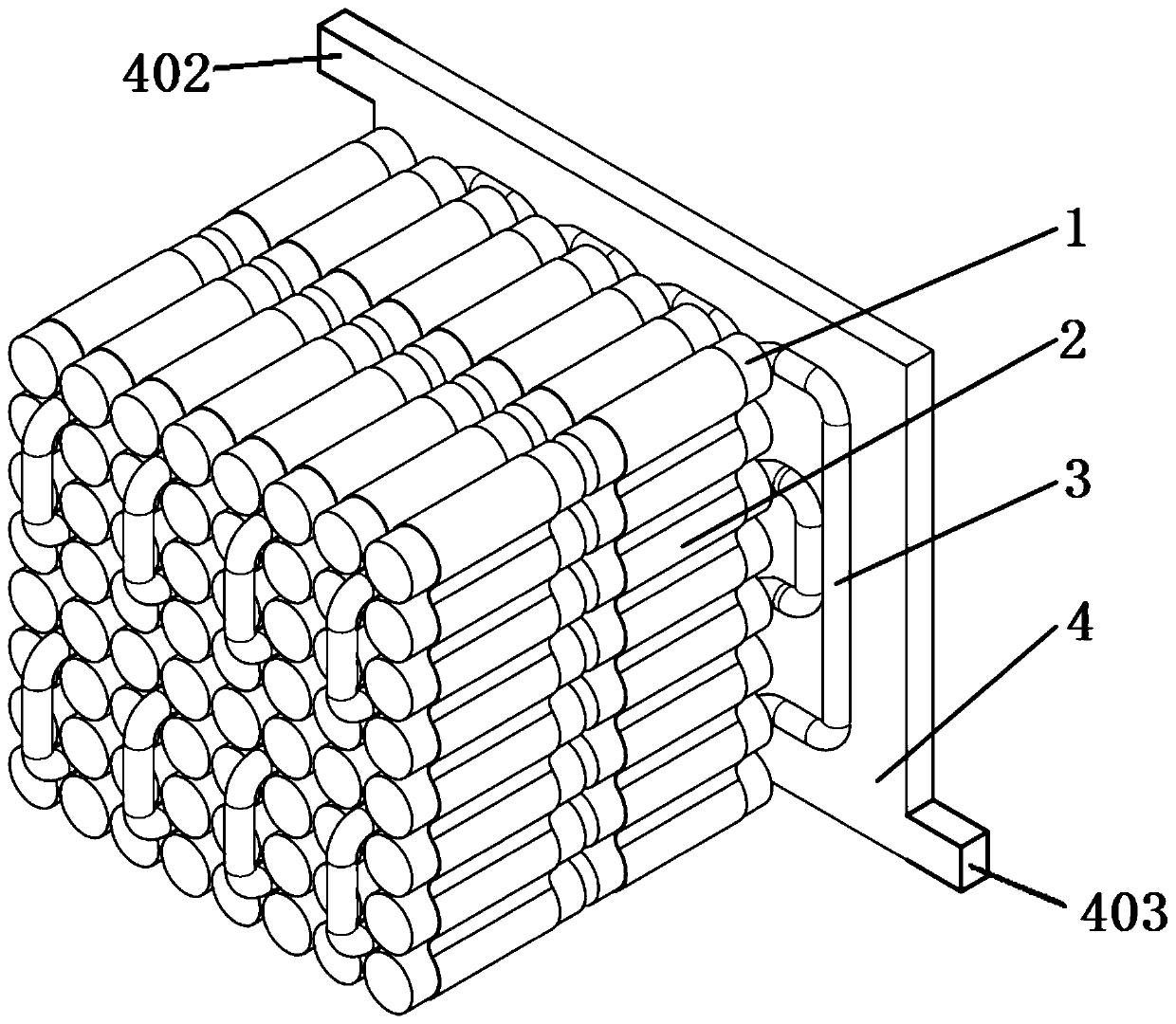

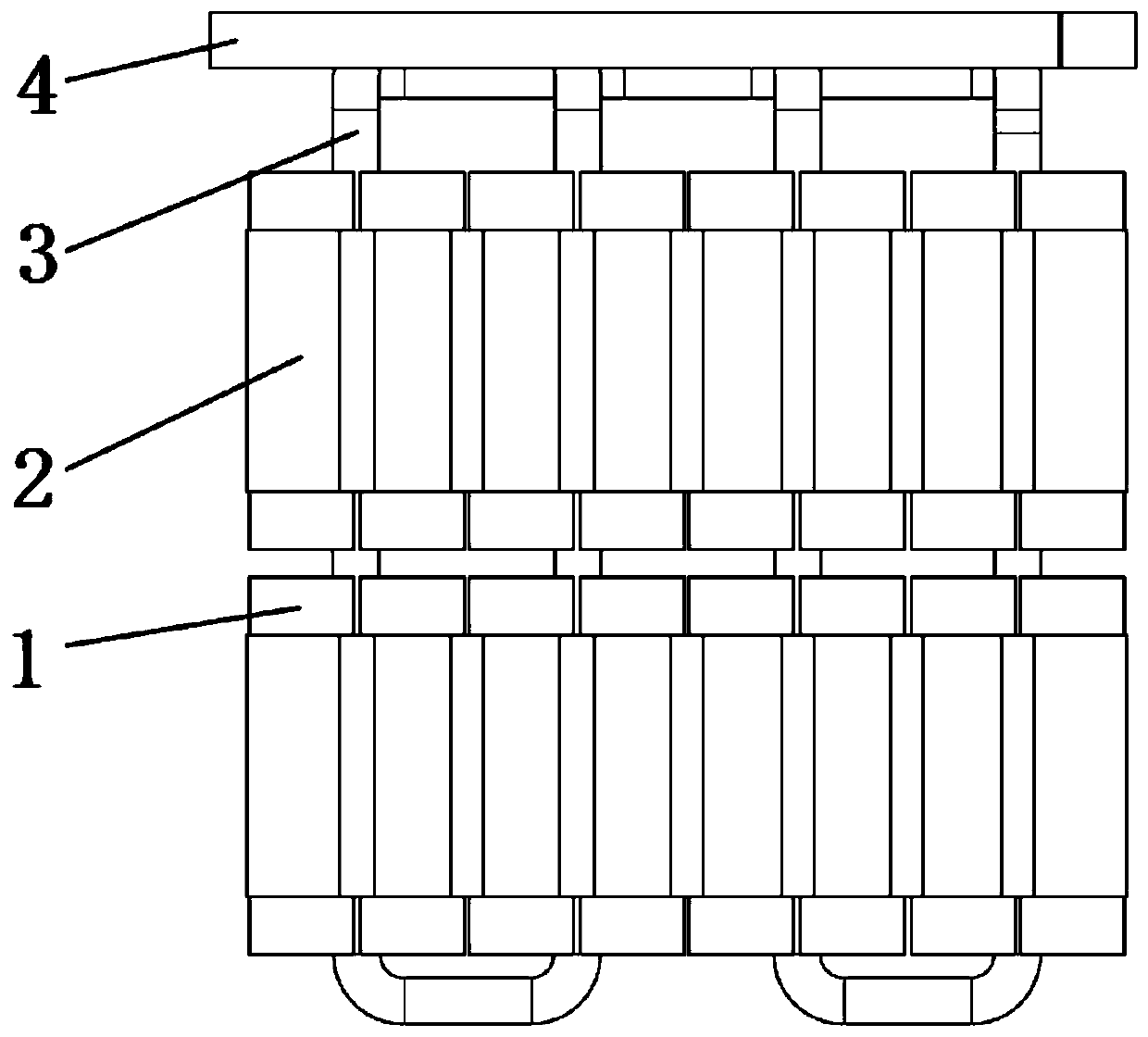

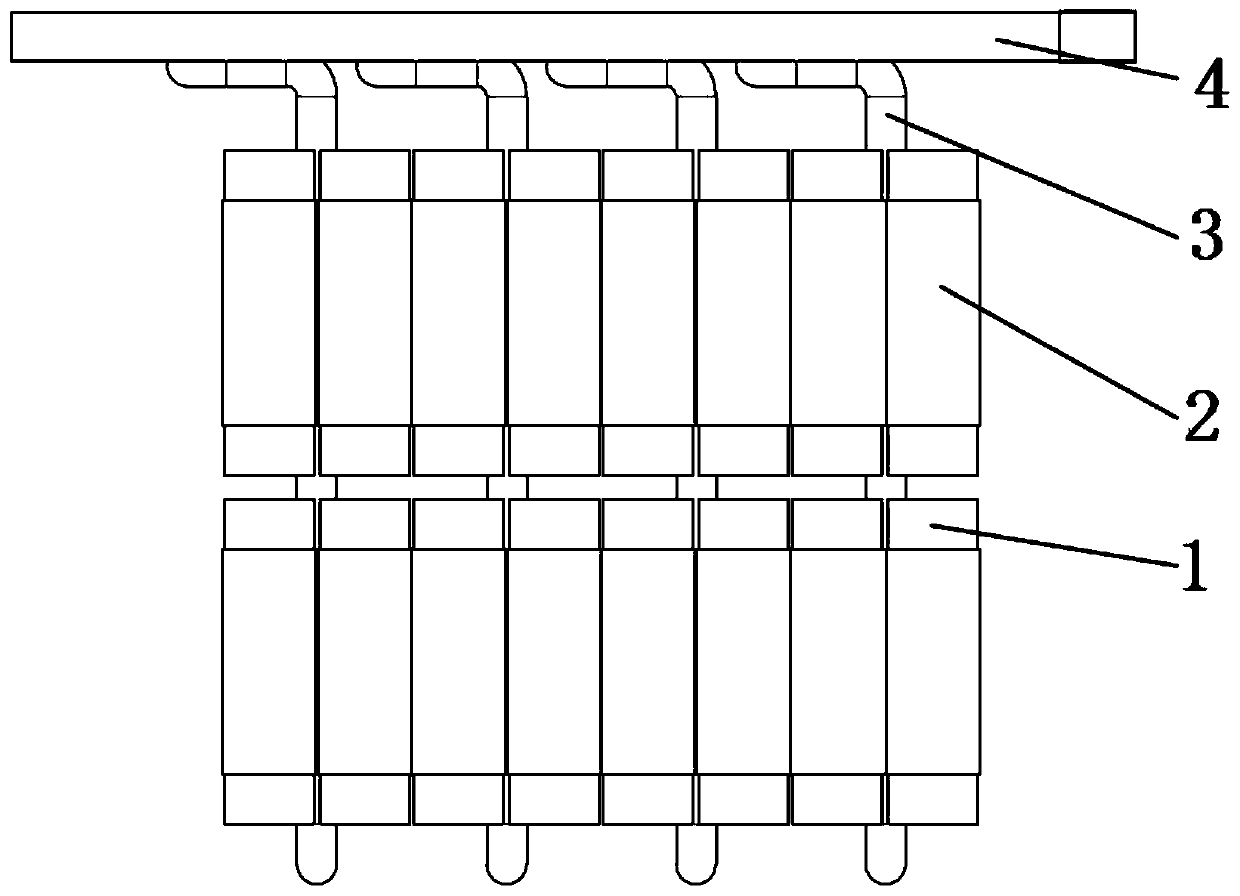

[0034] Such as Figure 1-Figure 3 A power battery liquid cooling device is shown, including a battery pack 1, a battery sleeve 2, a pulsating heat pipe 3 and a cooling channel 4 with cooling liquid inside; the battery pack 1 is arranged in the battery sleeve 2, and the pulsating heat pipe The evaporating section 301 of 3 is connected to the outer wall of the battery sleeve 2 , and the condensing section 302 of the pulsating heat pipe 3 is connected to the cooling channel 4 . The heat generated by the battery pack 1 is transferred to the cooling channel 4 through the battery sleeve 2 and the pulsating heat pipe 3 . The cooling channel 4 is only located on one side of the battery pack 1, and its design is reasonable and its structure is simple, which is beneficial to reduce energy consumption and make the structure of the liquid cooling device more compact. Among them, the pulsating heat pipe 3 is a serpentine capillary pipeline filled with working fluid inside, and the working...

Embodiment 2

[0043] Such as Figure 10 As shown, the length of the battery sleeve 2 that is farther away from the cooling channel 4 (or the condensation section 302 of the pulsating heat pipe 3 ) wrapping the battery pack 1 increases with the distance from the cooling channel 4 . Compared with the single battery 101 closer to the cooling channel 4, the thermal resistance between the single battery 101 farther from the cooling channel 4 and the cooling channel 4 is greater. By increasing the length of the battery sleeve 2 there, Increase the contact area between the battery sleeve 2 and the single battery 101 to reduce thermal resistance; this setting can further improve the overall temperature uniformity of the battery pack 1, and set battery sleeves of different lengths for the single battery 101 in different positions Cartridge 2 for better cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com