Leaf beet plant factory cultivation method

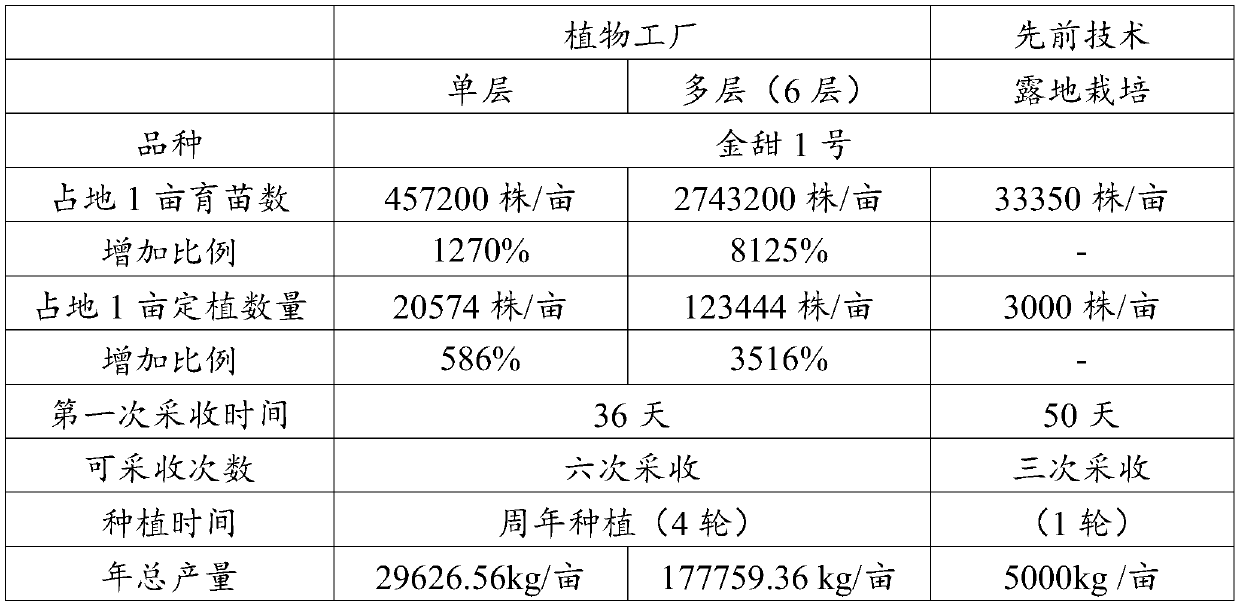

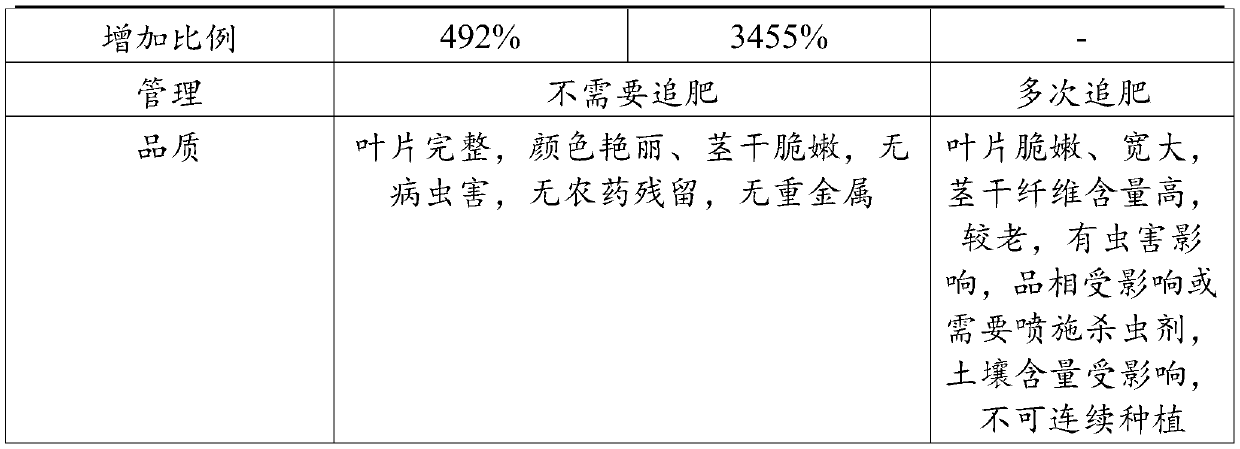

A cultivation method and technology of leaf beet, which is applied in the field of plant factory cultivation of leaf beet, can solve the problems of shortening harvest time, low germination rate, and irregular germination, so as to shorten harvest time, save germination, and reduce seed production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A plant factory cultivation method for leaf sugar beets, comprising the cultivation by adopting Zhongke M-series plant factory multi-layer planting modules, the specific steps are as follows:

[0037] (1) Seed treatment and germination: Soak the leaves of Jintian No. 1 sugar beet seeds in clean water for 12 hours, take out the sunken seeds and put them in a refrigerator at 5°C for 5 days at low temperature, then take out the petri dish and place it at a temperature of 18°C. Germination is carried out in a germination box with a relative humidity of 90%, and water is replenished in a timely manner every day until the seeds begin to whiten before sowing;

[0038] (2) Sowing: Fully moisten the rock wool, place it in the sowing tray, and then sow the white seeds downward in the rock wool, with a seeding density of 1200 plants / m 2 To improve the uprightness of the plant, the seeding tray was then placed in a germination box with a temperature of 18°C and a relative humidit...

Embodiment 2

[0044] A plant factory cultivation method for leaf sugar beets, comprising the cultivation by using Zhongke M-series plant factory single-layer planting modules, the specific steps are as follows:

[0045] (1) Seed treatment and germination: Put the leaves of Jintian No. 1 sugar beet seeds into clear water to soak for 12 hours, take out the sunken seeds and put them in H2O with a concentration of 15%. 2 o 2 Soak in the water for 30 minutes, the H 2 o 2 Rinse the seeds 6 times with clean water to remove H 2 o 2 residual; there will be no H 2 o 2 The remaining seeds are placed in a single layer in a petri dish covered with a layer of filter paper and covered with plastic wrap, and a few small holes are made on the plastic wrap for ventilation, and the petri dish is placed in a germination box with a temperature of 18°C and a relative humidity of 90% for germination , add water in a timely manner every day until the seeds start to blanch before sowing;

[0046] (2) Sowin...

Embodiment 3

[0052] A plant factory cultivation method for leaf sugar beets, comprising the cultivation by adopting Zhongke M-series plant factory multi-layer planting modules, the specific steps are as follows:

[0053] (1) Seed treatment and germination: Soak the leaves of Jintian No. 1 sugar beet seeds in clean water for 12 hours, take out the sunken seeds and put them in a refrigerator at 5°C for 5 days at low temperature, then take out the petri dish and place it at a temperature of 18°C. Germination is carried out in a germination box with a relative humidity of 90%, and water is replenished in a timely manner every day until the seeds begin to whiten before sowing;

[0054] (2) Sowing: Fully moisten the rock wool, place it in the sowing tray, and then sow the white seeds downward in the rock wool, with a seeding density of 1200 plants / m 2 , gently press down, and the surface of the seeds can expose the rock wool to improve the uprightness of the plants, and then place the seeding tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com