Disc bracket assembly of multi-function disc separator with multi-flow channels

A disc separator and bracket component technology, which is applied in the field of disc bracket components of multifunctional disc separators, can solve the problems of closed cross-section, easy blockage of flow channels, narrow use range, etc., and achieve the goal of preventing holes Blockage, easy to clean up silt, easy to process and manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, the present invention will be further described:

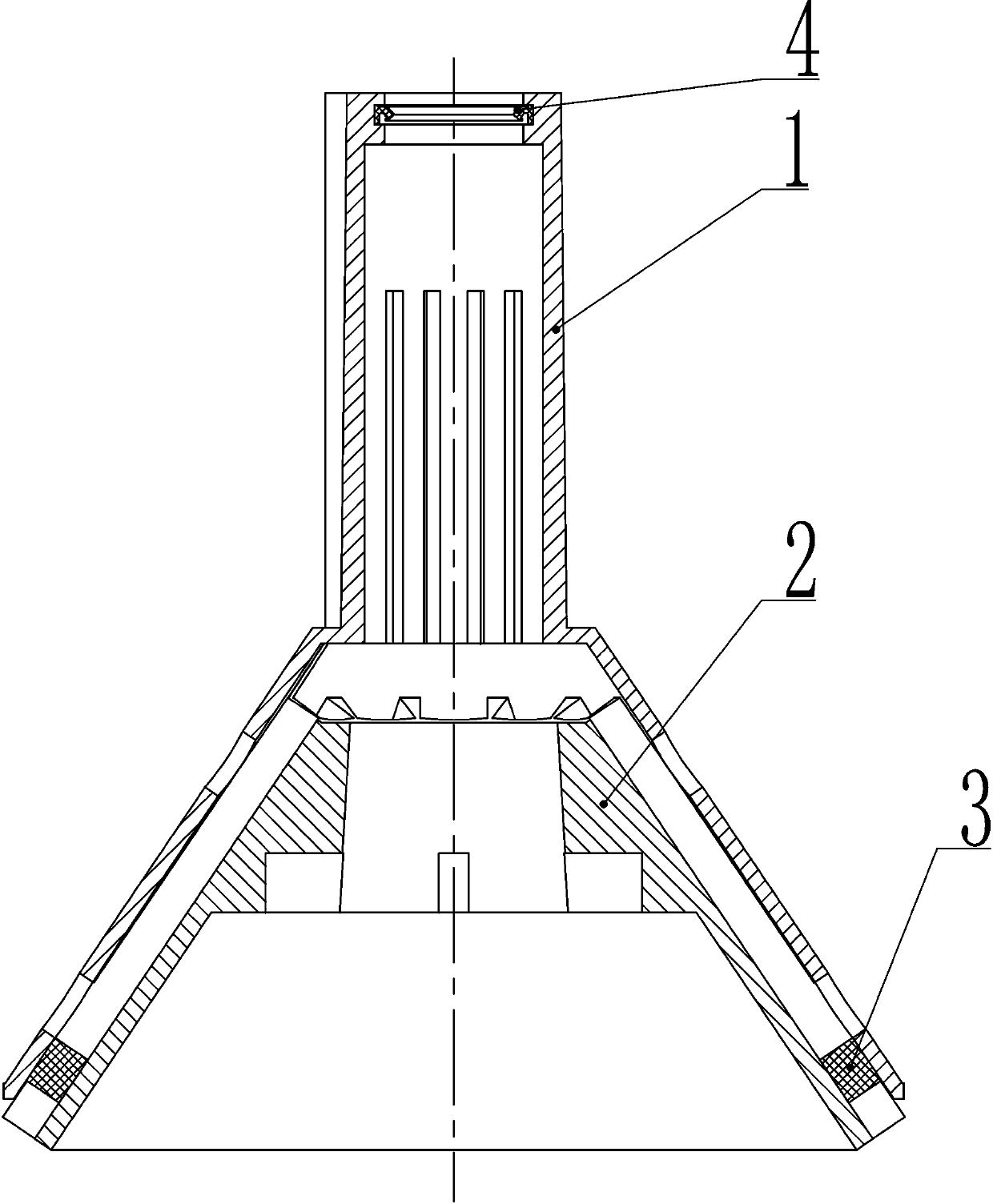

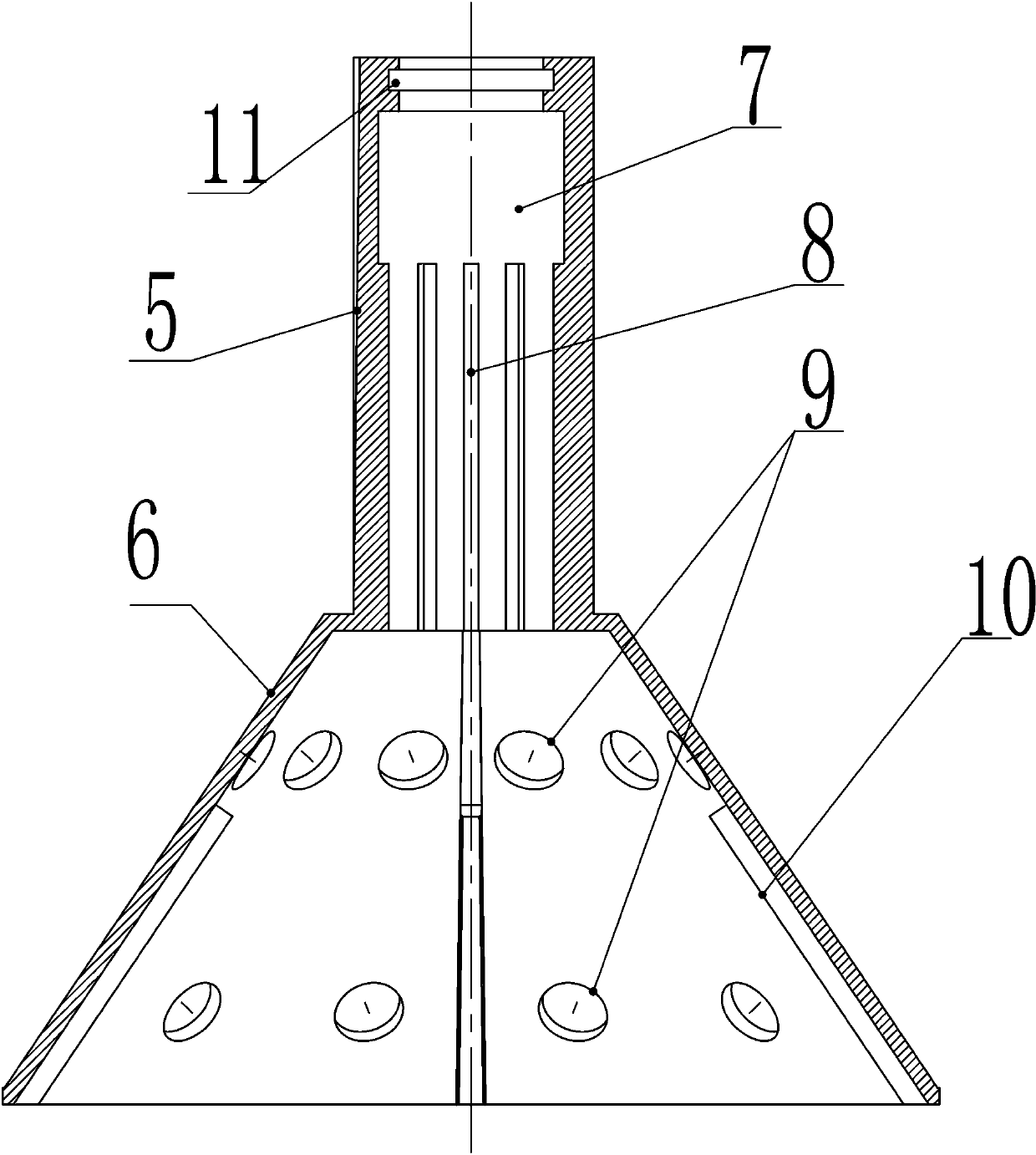

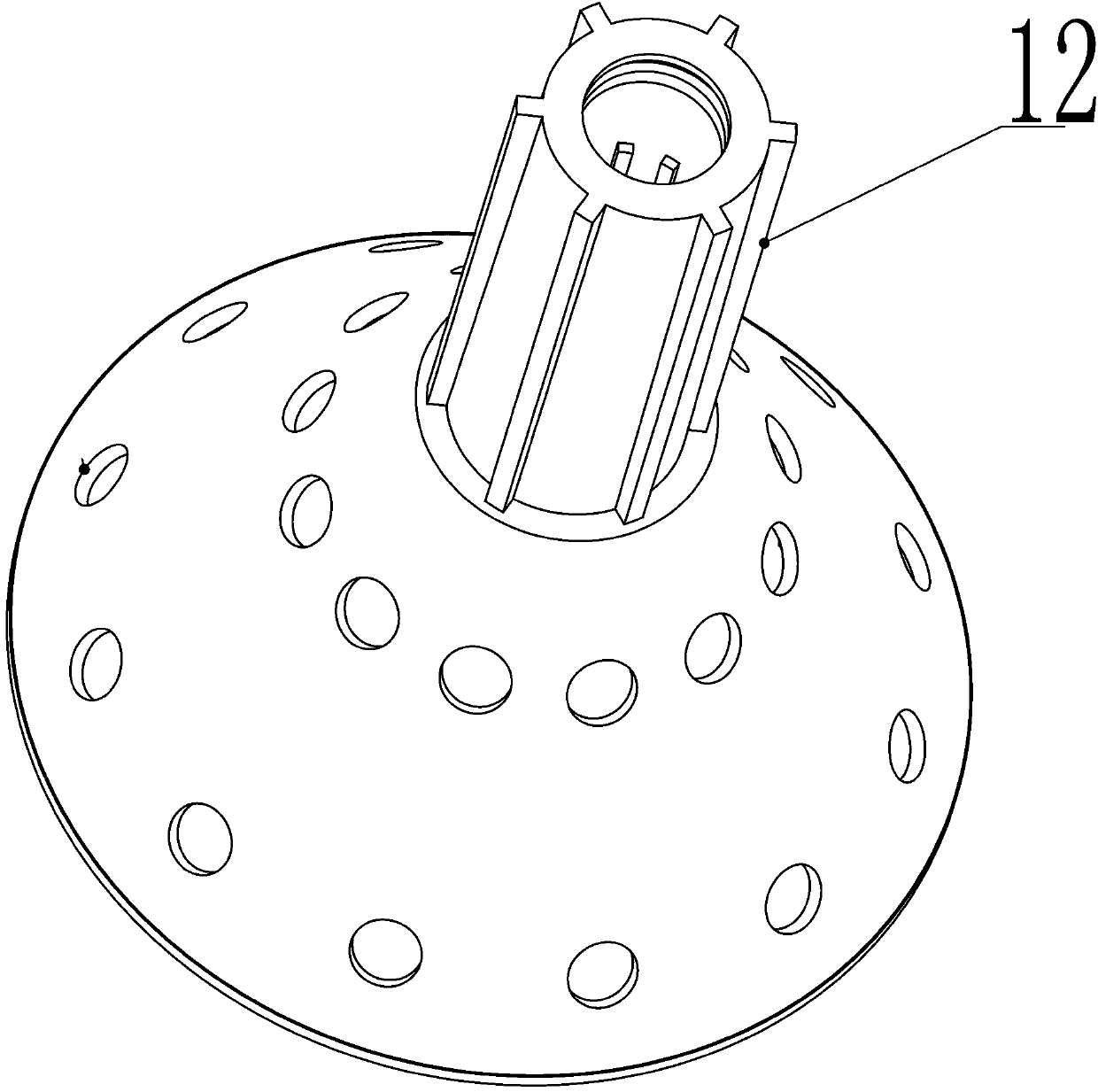

[0033] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, a disc bracket assembly of a multi-channel multi-functional disc separator includes a disc bracket 1, a disc bracket base 2, a plug 3 and a sealing ring 4, and the disc bracket 1 It includes an integrated upper column portion 5 and a lower cone portion 6, the outer peripheral surface of the upper column portion 5 is a cylindrical surface or a small tapered conical surface with an upper diameter smaller than the lower diameter, and an outer rib 12 protrudes from the outer peripheral surface of the upper column portion 5. For clamping the disc, a round through hole is opened on the top of the upper column part 5, and an annular sealing ring groove 11 is arranged on the inner wall of the round through hole. The upper end is used to insert the feed pipe 22, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com