Maintenance robot for wind power tower barrel

A technology for wind power towers and robots, which is applied in the field of climbing machinery and equipment, can solve the problems of insufficiency of operation facilities, increase the difficulty of construction operations, and low construction efficiency, and achieve the effects of convenient operation and operation, high construction efficiency, and reduced labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

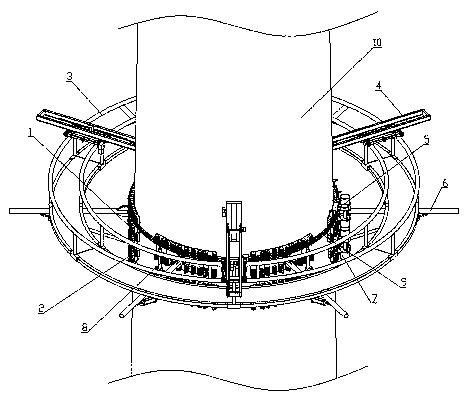

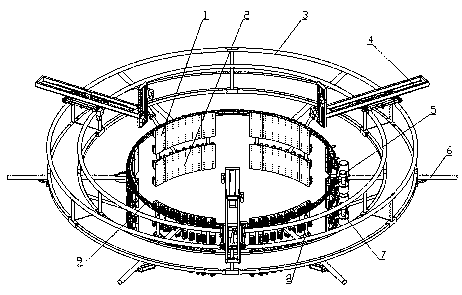

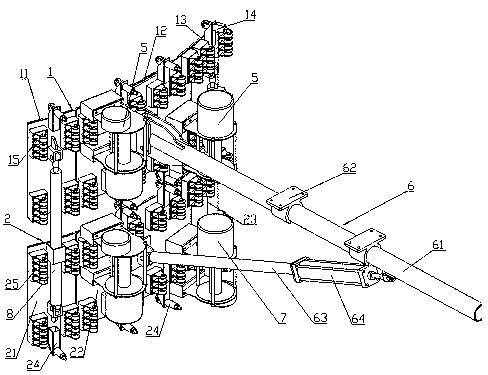

[0047] Such as figure 1 , figure 2 In the shown wind power tower maintenance robot, the climbing robot includes a tower upper ring and a tower lower ring surrounding the wind power tower 10 . The upper ring of the tower tube and the lower ring of the tower tube respectively include six upper tube-holding plates 1 and lower tube-holding plates 2, and the six upper tube-holding plates 1 at the same height surround the tower tube along the same circumferential direction of the fan tower. For the upper ring, six lower tube boards 2 located at another height enclose the lower ring of the tower along the other circumferential direction of the wind turbine tower.

[0048] Two upper hoists 5 are installed on an upper tube-holding plate 1 of the upper ring of the tower tube, and upper steel cable guides 15 are installed on the six upper tube-holding plates 1 that constitute the upper ring of the tower tube. The steel cables 9 corresponding to the winches 5 are wound on the outside o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com