Light rail lifting cabin for wind power generation tower barrel

A tower tube and light rail technology, which is applied in the field of light rail lift cabins, can solve problems such as low work efficiency, high work intensity, and uncoordinated development of the times, and achieve the effects of simple structure, low manufacturing cost, and easy access to and from the work room

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

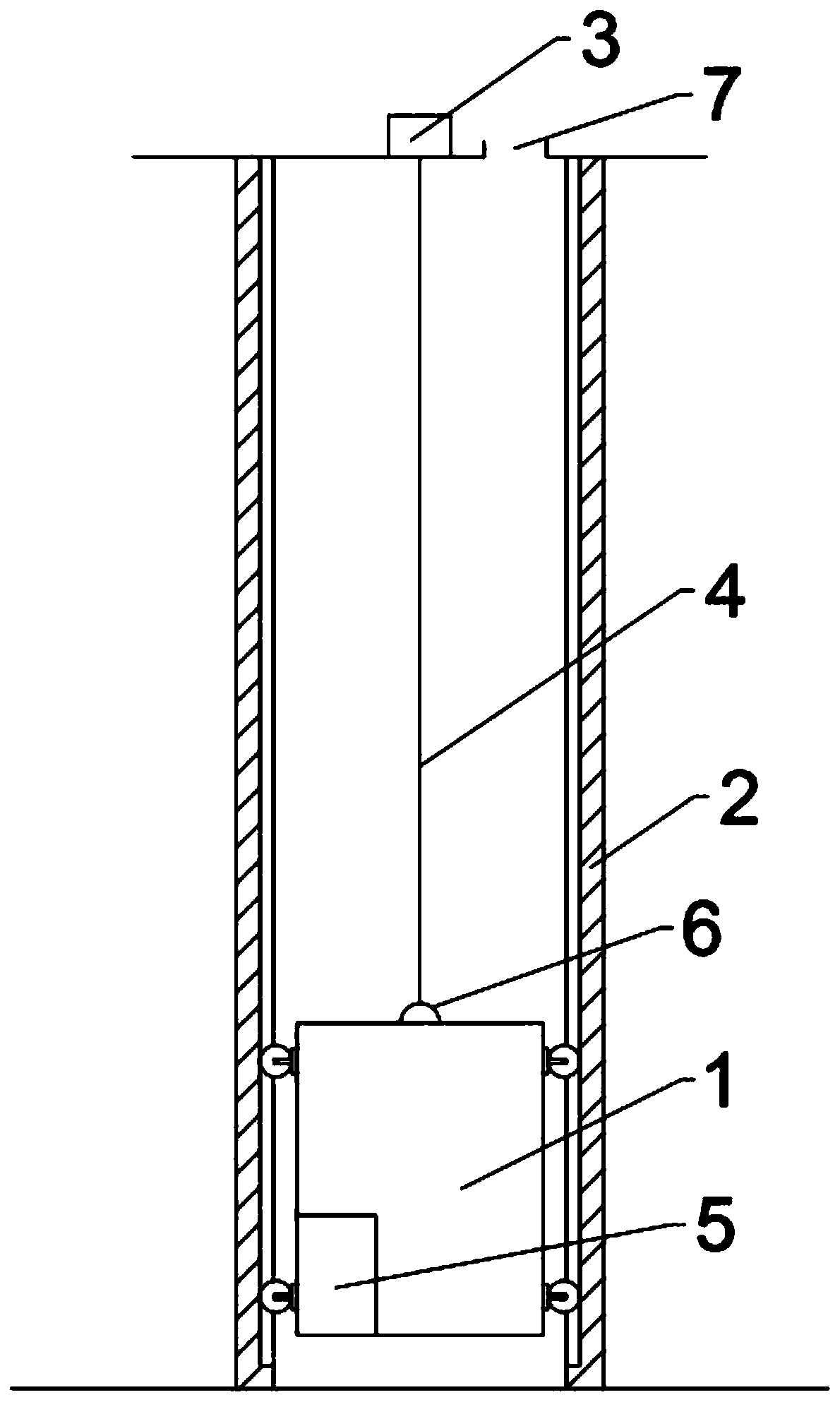

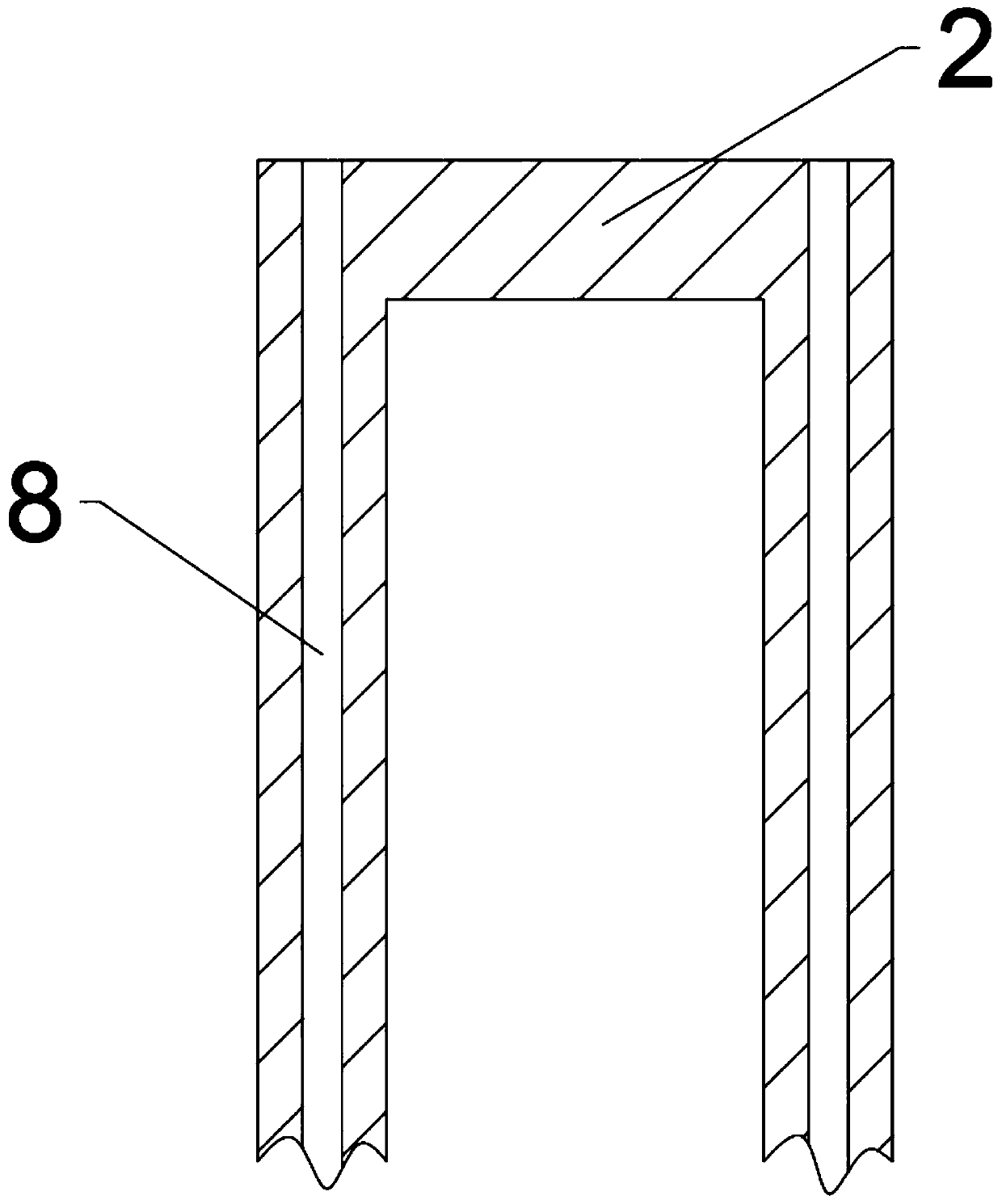

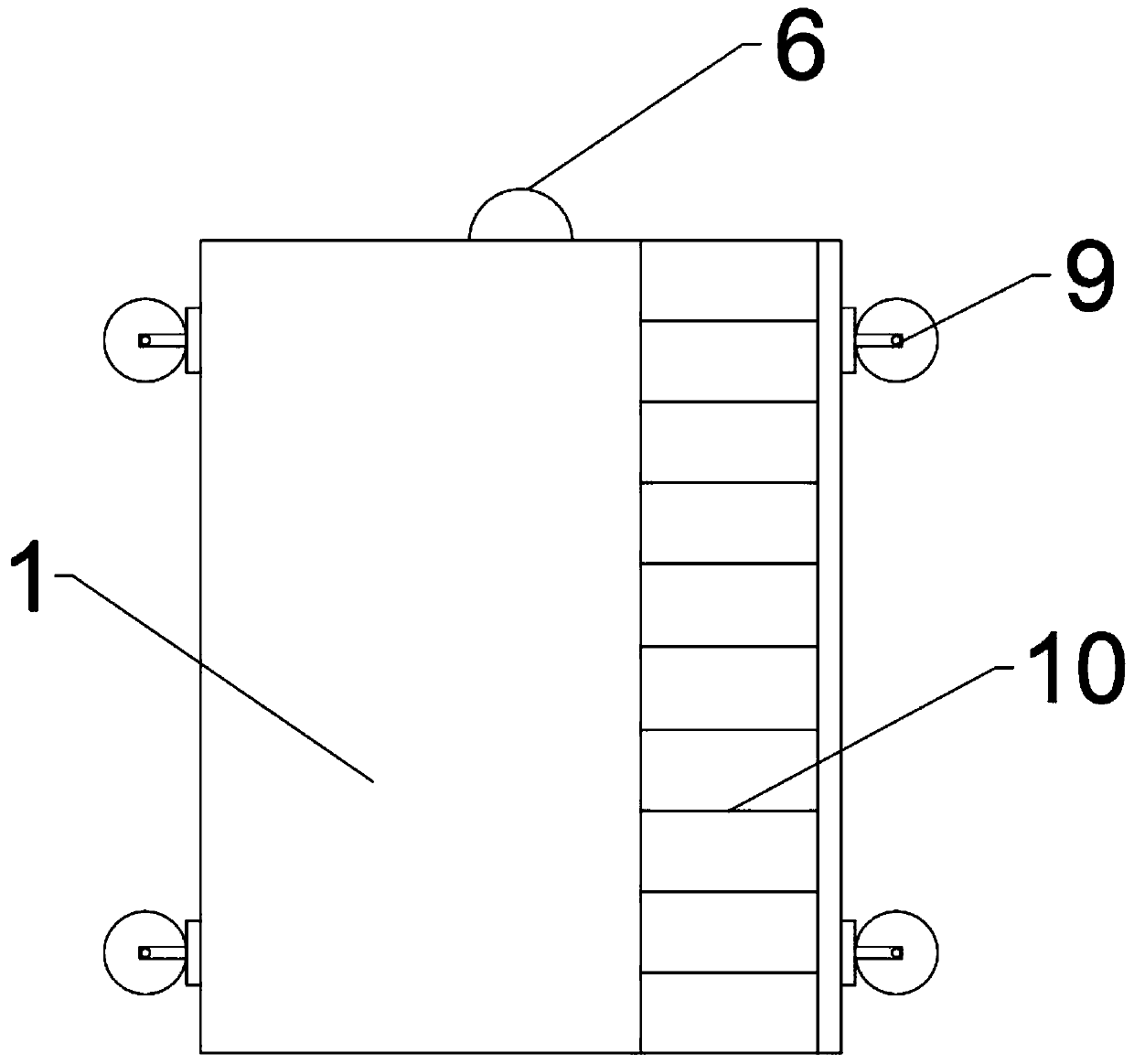

[0024] Refer to attached Figure 1-2 , this embodiment provides a light rail lift cabin for a wind power generation tower, the light rail lift cabin is installed in the wind power generation tower, and can directly lead to the workshop at the top of the tower; specifically, the light rail lift cabin includes a manned Cabin 1, the above-mentioned manned cabin 1 is arranged in the tower, and the top of the above-mentioned manned cabin 1 is fixed with a suspension ring 6, and the above-mentioned suspension ring 6 is tied with a steel strand 4, and the above-mentioned steel strand 4 and the electric winch 3 Connected, the above-mentioned electric winch 3 is installed on the top of the tower.

[0025] Wherein, the electric winch 3 can select the common deceleration electric winch in the prior art for use, also can select the electric winch of the prior art for use; By driving the electric winch 3, the steel strand 4 can be retracted, thereby can drive the manned cabin 1. Rising or...

Embodiment 2

[0030] Refer to attached figure 1 and 3 , in order to facilitate the staff in the manned cabin 1 to smoothly enter the workroom at the top of the tower, this embodiment is improved on the basis of embodiment 1. Specifically, the above-mentioned manned cabin 1 is equipped with a ladder 10, The top of the above-mentioned manned cabin 1 is provided with a through hole, which is connected with the ladder 10, and the above-mentioned ladder 10 is used for the staff to enter and exit the work room on the top of the tower tube; the bottom of the above-mentioned work room is provided with an entrance 7 corresponding to the ladder 10 . When the manned cabin 1 rises to the top, the staff can climb into the workroom at the top of the tower through the ladder 10 in the manned cabin 1 and the entrance 7 at the bottom of the workroom.

[0031] The light rail lift compartment provided by the present invention, when in use, the staff can enter the manned compartment 1 through the manned comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com