Castor oil-based double-crosslinkable reactive resin monomer and preparation method thereof

A castor oil-based, active resin technology, applied in the field of unsaturated resins, can solve the problems of high content of toxic components, complex formula, high volatility, etc., and achieve the effects of improving comprehensive performance, simple product preparation process, and environmental protection in the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

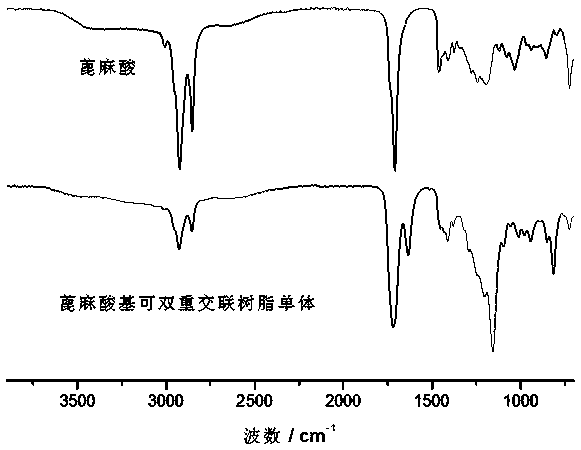

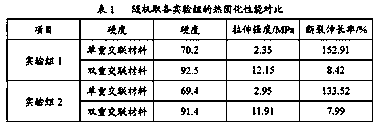

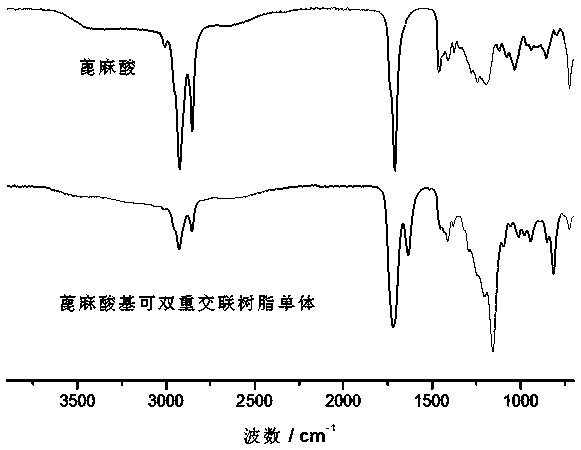

[0020] Add ricinoleic acid to the reaction vessel, then add epichlorohydrin in the ratio of ricinoleic acid to epichlorohydrin molar ratio of 1:6, and then add 0.5% of the total mass of the reaction raw materials benzyl triethyl chloride Ammonium, react at 115°C for 2h; lower the temperature to 60°C, add calcium oxide and sodium hydroxide equal to the carboxyl group, and stir for 3h at 60°C; finally, filter by suction and remove excess epichlorohydrin by rotary evaporation. Castor oil-based intermediate active monomer A; the prepared castor oil-based intermediate active monomer A and 0.5% of the total mass of the reactant N,N dimethylbenzylamine are added to the reactor, and the temperature is raised to 60°C, Then acrylic acid was added dropwise to it, and the molar ratio of the acrylic acid to the castor oil-based intermediate active monomer A was 1:1. After the addition, the reaction was performed at 115°C for 2.5 hours to obtain the castor oil-based intermediate active monome...

Embodiment 2

[0022] Add ricinoleic acid to the reaction vessel, then add epichlorohydrin in a ratio of 1:9 molar ratio of ricinoleic acid to epichlorohydrin, and then add 1.5% tetraethylammonium bromide of the total mass of the above reaction raw materials, React at 120°C for 2h; cool down to 60°C, add calcium oxide and sodium hydroxide equal to the carboxyl group, and stir for 3h at 60°C; finally, filter by suction and remove excess epichlorohydrin by rotary evaporation to obtain castor oil The intermediate active monomer A based on castor oil; the castor oil-based intermediate active monomer A and 1.5% of the total mass of the reactant are added to the reactor, the temperature is raised to 80 ℃, and then 2 -Ethyl acrylic acid, the molar ratio of the 2-ethyl acrylic acid to the castor oil-based intermediate active monomer A is 1:1, after the dropping is completed, react at 120°C for 1.5 hours to obtain the castor oil-based intermediate active monomer B ; Then the prepared castor oil-based ...

Embodiment 3

[0024] Add ricinoleic acid to the reaction vessel, then add epichlorohydrin in a ratio of 1:7 molar ratio of ricinoleic acid to epichlorohydrin, and then add 1.0% tetramethylammonium bromide of the total mass of the above reaction raw materials, React at 117.5°C for 2h; lower the temperature to 60°C, add calcium oxide and sodium hydroxide equal to the carboxyl group, and stir for 3h at 60°C; finally, after suction filtration, the excess epichlorohydrin is removed by rotary evaporation to obtain castor oil Add the prepared castor oil-based intermediate active monomer A and N,N dimethylbenzylamine accounting for 1.0% of the total mass of the reactants into the reactor, heat up to 70 ℃, and then The methacrylic acid was added dropwise, and the molar ratio of the methacrylic acid to the castor oil-based intermediate active monomer A was 1:1. After the dropping was completed, the reaction was performed at 118°C for 2.0 hours to obtain the castor oil-based intermediate active monomer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com