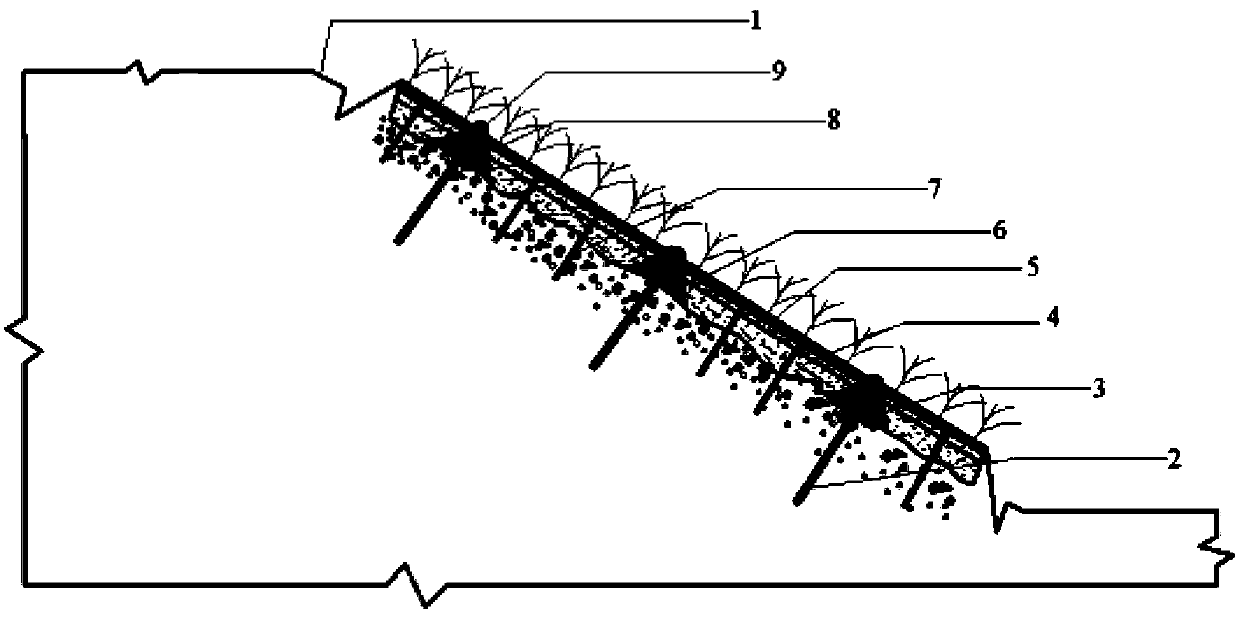

Ecological protection structure of crushed rock side slope dry spray construction frame lattice beams and base material and method

A technology for rock crushing and ecological protection, which is applied in infrastructure engineering, botanical equipment and methods, and excavation. It can solve the problems of complex procedures, long construction periods, multiple sets of mechanical equipment, etc. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A weathered rock slope with an annual rainfall of 600-900 mm in a southern region has a slope of 1:1. It is planned to use the present invention for ecological slope protection.

[0036] The dry-blasting mortar adopts a mixed mortar with a strength grade of M15, and a polycarboxylate high-performance water-reducing agent with a water-reducing rate of 25% is added to the formula.

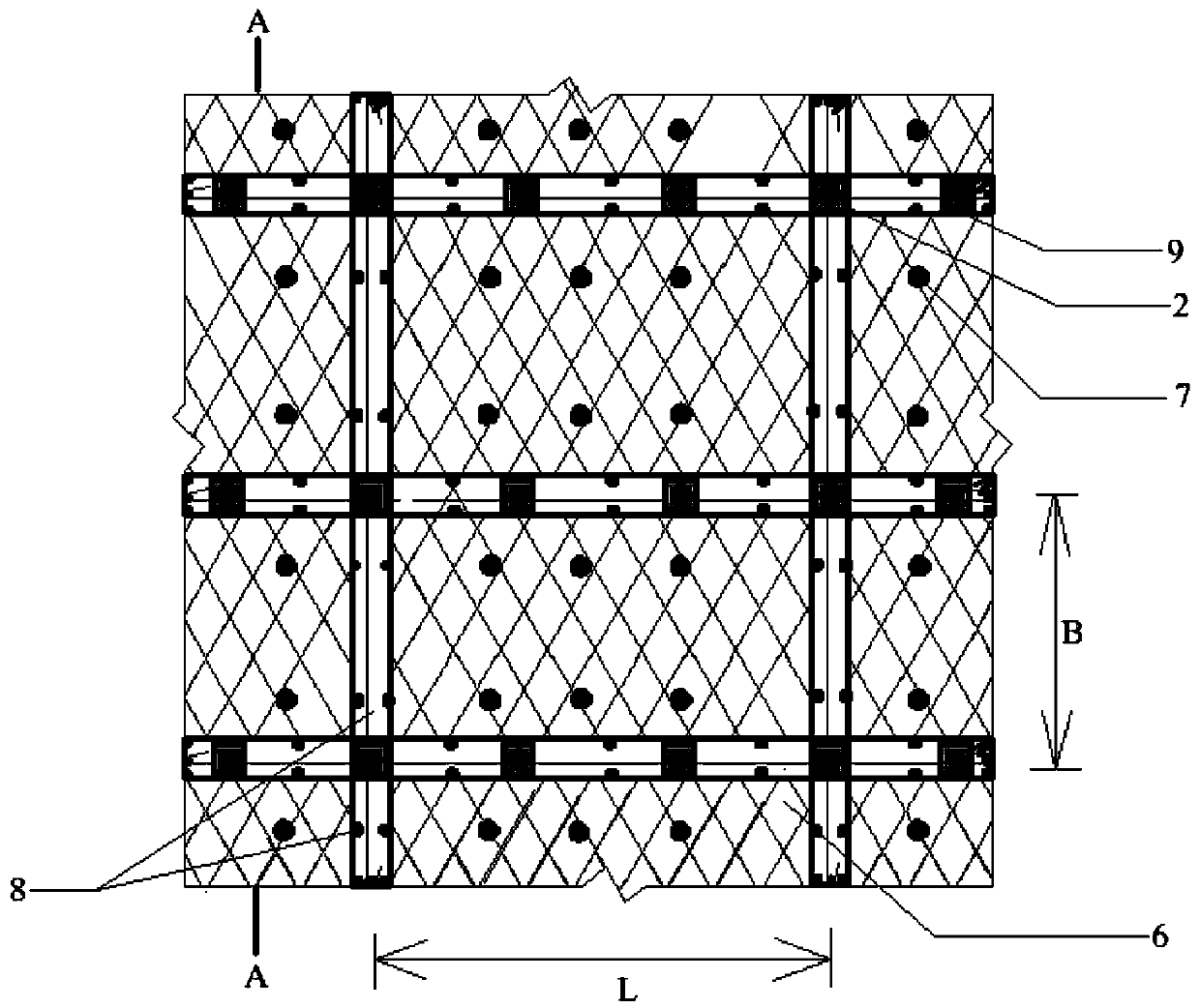

[0037] The sash formed by the sash beams 3 has a length L of 4 m and a width B of 4 m.

[0038] The base layer 4 is composed of loam, cement, organic matter, water retaining agent, and improved vegetation concrete greening additive, wherein the cement is 30 L / m 3 , organic matter 50 L / m 3 , water retaining agent (volume ratio) accounted for 0.08%, improved vegetation concrete greening additive 20L / m 3 .

[0039] The surface layer 5 is composed of loam, soil binder, compound fertilizer and plant seeds, wherein the soil binder (volume ratio) accounts for 0.01%, and the compound fertilizer is ...

Embodiment 2

[0050] For a broken limestone slope with an annual rainfall of 900-1200 mm in a southern region, the slope is 1:0.2, and the invention is proposed to be used for ecological slope protection.

[0051] The dry-blasting mortar adopts a mixed mortar with a strength grade of M15, and a polycarboxylate high-performance water-reducing agent with a water-reducing rate of 25% is added to the formula.

[0052] The sash formed by the sash beams 3 has a length L of 1.5 m and a width B of 1.5 m.

[0053] The base layer 4 is composed of loam, cement, organic matter, water retaining agent, and improved vegetation concrete greening additive, wherein cement 50 L / m 3 , organic matter 80 L / m 3 , water retaining agent (volume ratio) accounted for 0.1%, improved vegetation concrete greening additive 30L / m 3 .

[0054] The surface layer 5 is composed of loam, soil binder, compound fertilizer and plant seeds, wherein the soil binder (volume ratio) accounts for 0.02%, and the compound fertilizer is ...

Embodiment 3

[0065] For a broken shale slope with an annual rainfall of more than 1200 mm in a southern region, the slope is 1:0.5, and the invention is proposed to be used for ecological slope protection.

[0066] The dry-blasting mortar adopts a mixed mortar with a strength grade of M15, and a polycarboxylate high-performance water-reducing agent with a water-reducing rate of 25% is added to the formula.

[0067] The sash formed by the sash beams 3 has a length L of 2.5 m and a width B of 2.5 m.

[0068] The base layer 4 is composed of loam, cement, organic matter, water retaining agent, and improved vegetation concrete greening additive, wherein cement is 40 L / m 3 , organic matter 70 L / m 3 , water retaining agent (volume ratio) accounted for 0.09%, improved vegetation concrete greening additive 26L / m 3 .

[0069] The surface layer 5 is composed of loam, soil binder, compound fertilizer and plant seeds, wherein the soil binder (volume ratio) accounts for 0.015%, and the compound ferti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com