Hydrostatic hydraulic flushing and suction sinking well construction method

A construction method and hydraulic flushing technology, applied in caissons, infrastructure engineering, construction, etc., to achieve the effects of improving construction quality, saving construction resources, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

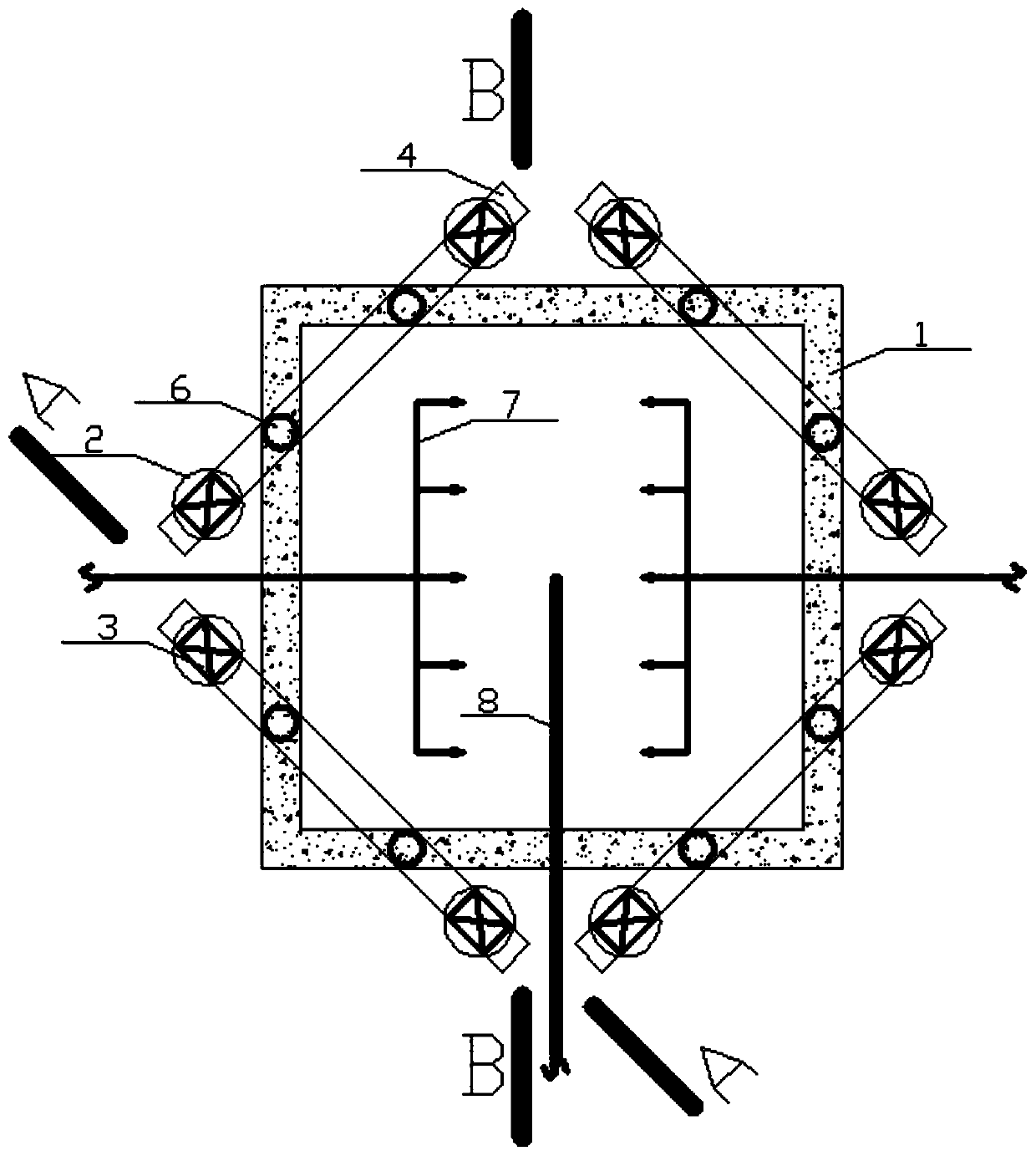

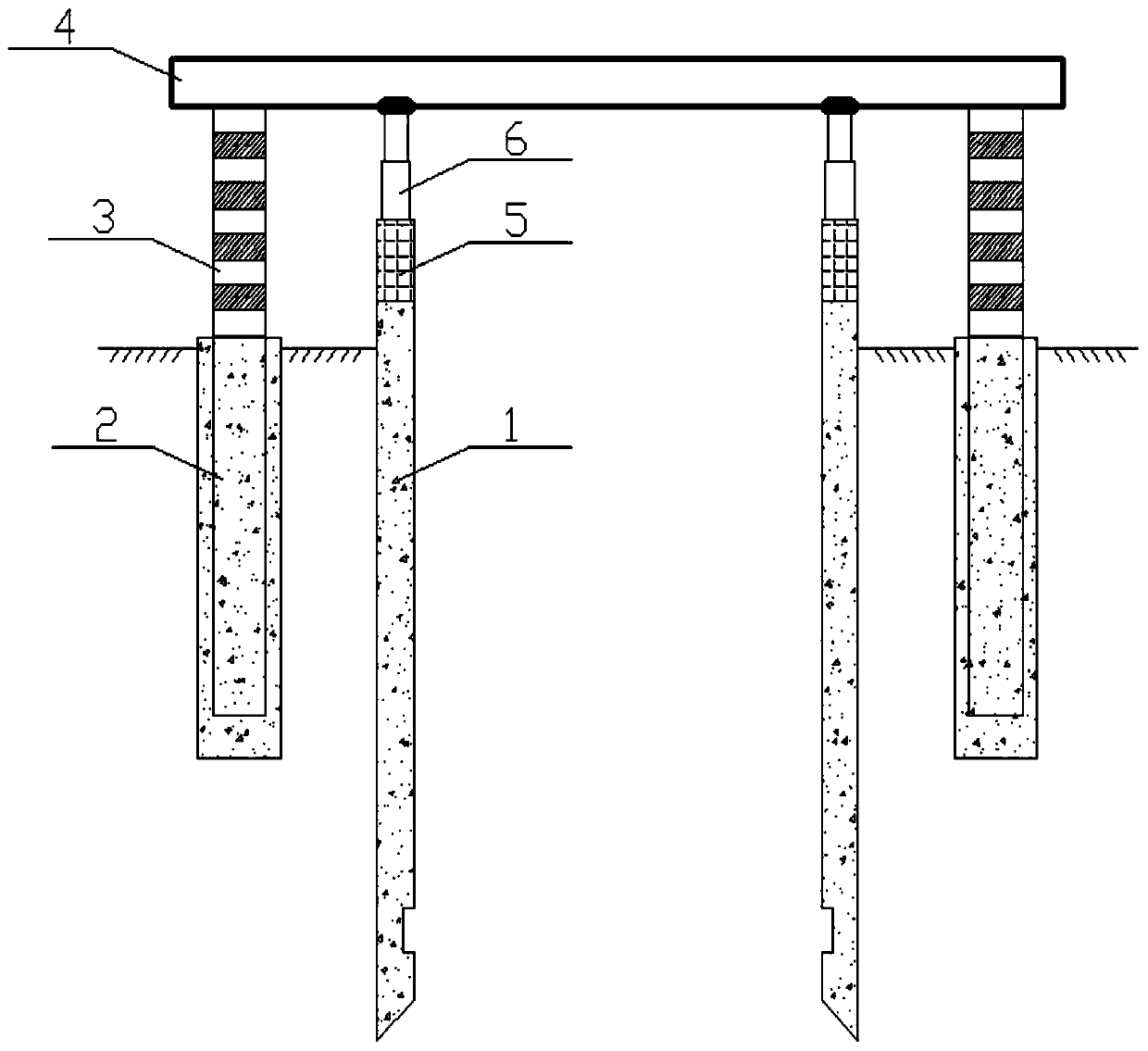

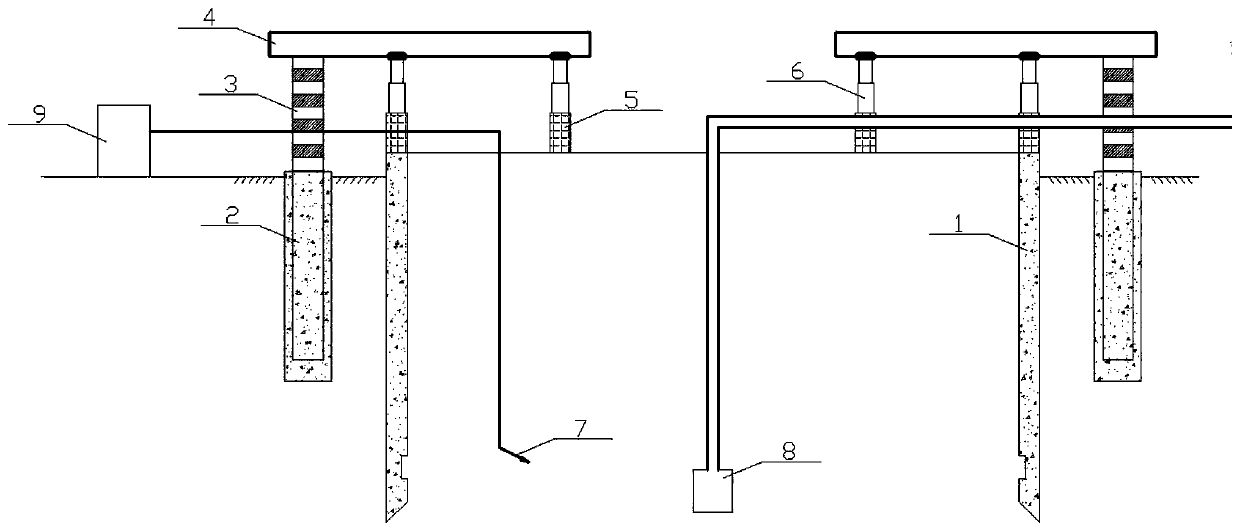

[0022] Such as figure 1 , figure 2 , image 3 Shown, a kind of static pressure hydraulic suction caisson construction method, the steps are as follows:

[0023] 1) Before the prefabrication of the well body 1, construct the cast-in-place piles 2 symmetrically on the outside of the four corners of the well body 1, control the elevation of the pile top to 0.5 meters above the ground, and insert the steel lattice columns 3, wherein the steel lattice columns 3 are inserted into the cast-in-place piles 2 3 meters, exposed 2 meters.

[0024] 2) Install a shaped steel beam 4 at the end of the steel lattice column 3 at the same angle of the shaft 1, and weld the shaped steel beam 4 and the steel lattice column 3 firmly. Such as figure 1 As shown, the four corners of the well body 1 are provided with shaped steel beams 4, and the shaped steel beams 4 on the two opposite corners of the well body 1 are parallel to each other, which are used to maintain the stability of the entire we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com