Loop heat pipe heat radiator with vapor-liquid two-phase flow jetting and pressure boosting device

一种升压装置、环路热管的技术,应用在环路热管散热器,热管散热装置领域,能够解决供液不足、升高工质压力、增加沸腾池液体供给等问题,达到减小影响、简化冷却系统的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

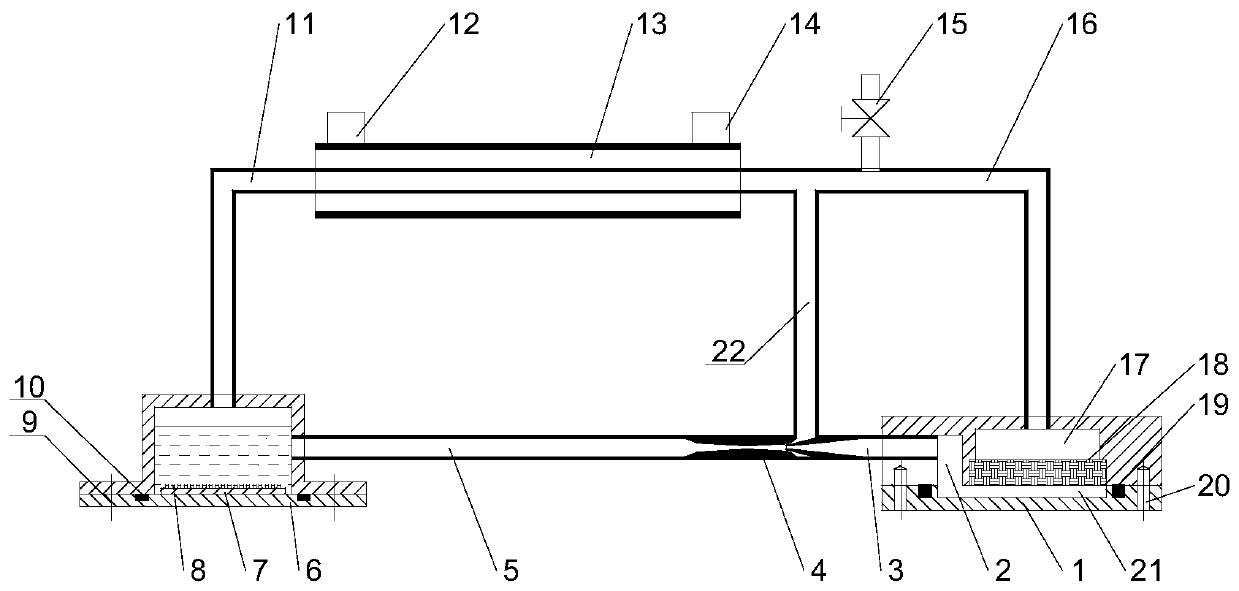

[0028] see figure 1 , the loop heat pipe cooling device with vapor-liquid two-phase flow jet boosting device of the present invention includes evaporator 1 , vapor-liquid two-phase flow jet boosting device 4 , boiling pool 6 and condenser 13 .

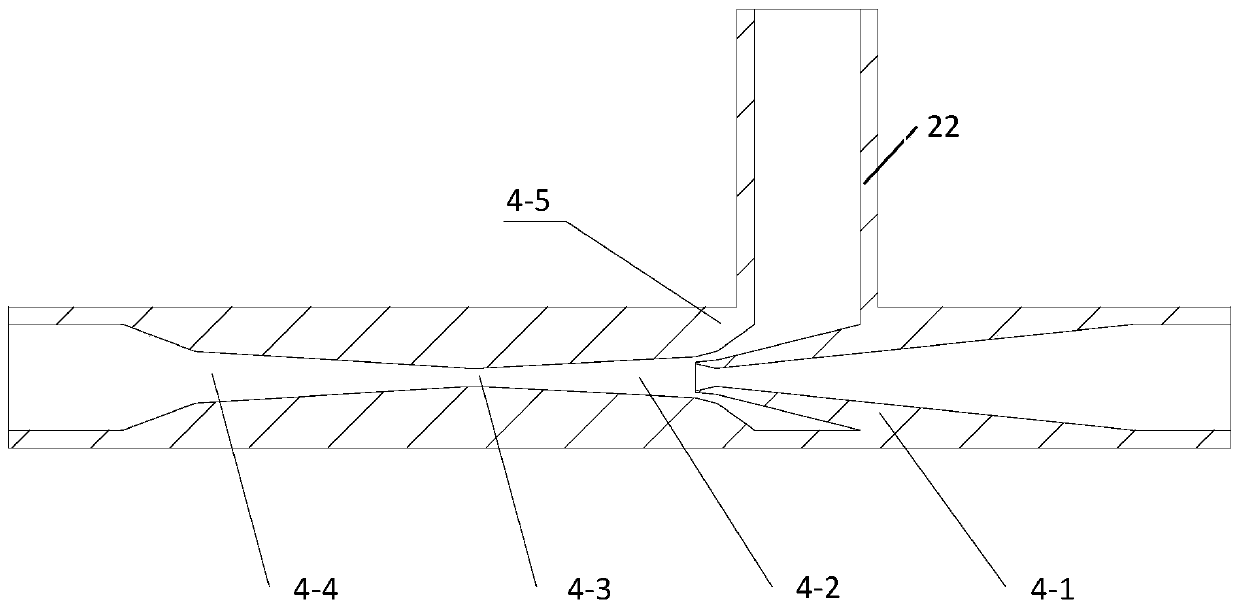

[0029] like figure 2As shown, the vapor-liquid two-phase flow injection booster 4 is composed of a steam nozzle 4-1, a liquid nozzle 4-5, a mixing chamber 4-2, a throat 4-3 and a diffusion section 4-4. One end of the steam nozzle 4-1 extends into the inside of the liquid nozzle 4-5, the inlet of the mixing chamber 4-2 communicates with the steam nozzle 4-1 and the liquid nozzle 4-5, and the liquid nozzle 4-5 connected to the condenser outlet Arranged on the periphery of the steam nozzle 4-1, a communicating throat 4-3 and a diffuser section 4-4 are sequentially arranged at the outlet of the mixing chamber 4-2. The steam noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com