Resistive flexible strain sensor based on drying-mediated self-assembly, and preparation method of resistive flexible strain sensor

A strain sensor, resistive technology, applied in the field of flexible sensors, resistive flexible strain sensors and their preparation, can solve the problems of difficult processing, high technical requirements, long preparation cycle of flexible strain sensors, etc., and achieve simple and environmentally friendly preparation process, application The effect of broad prospects and shortening the preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

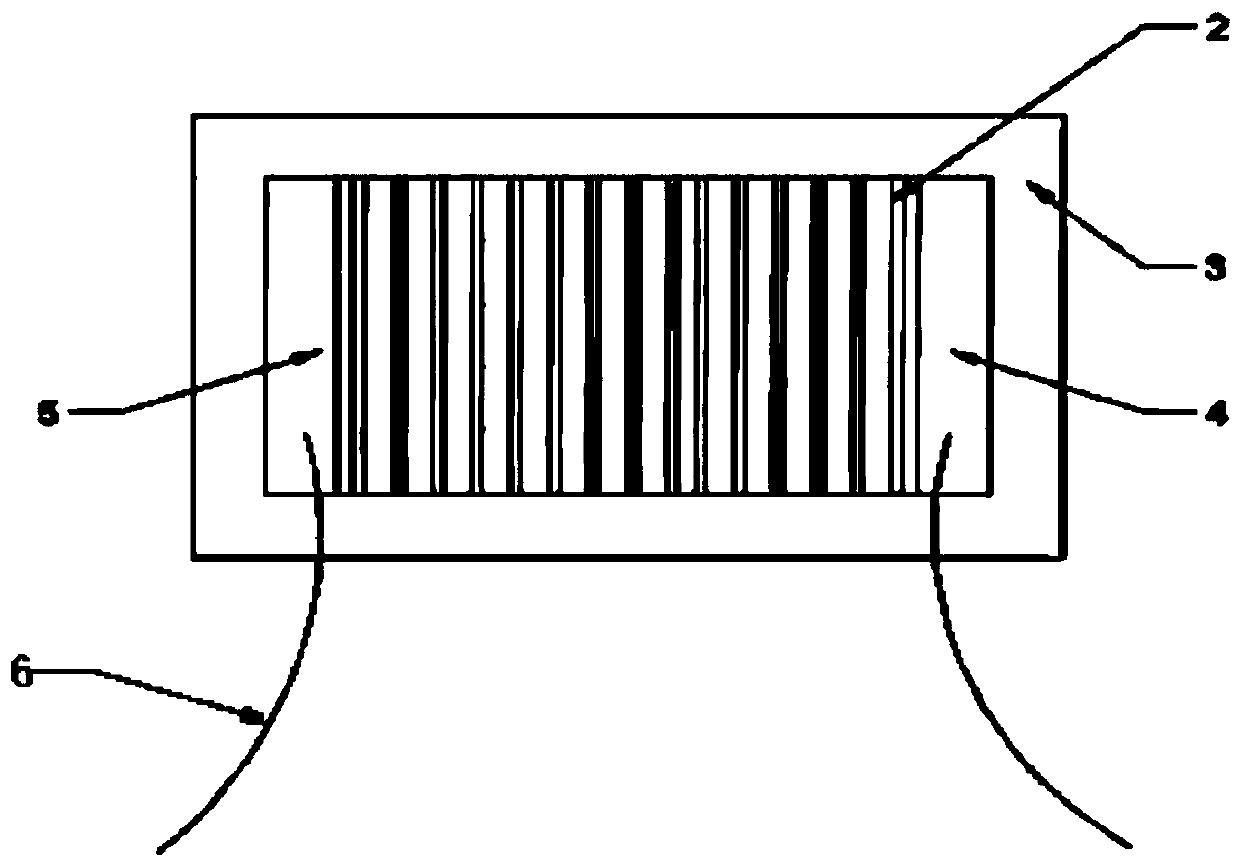

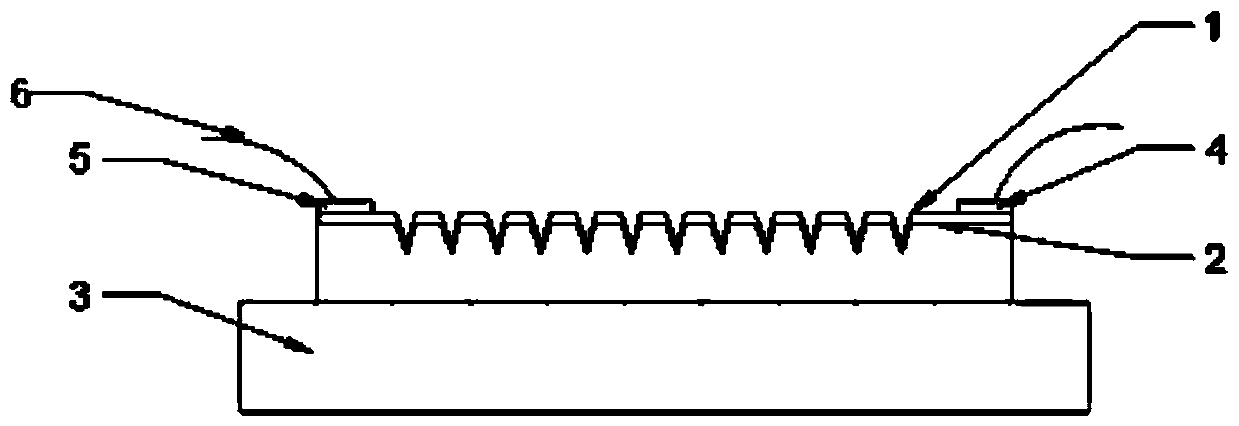

[0060] A flexible strain sensor based on desiccation-mediated self-assembly, such as figure 1 , 2 As shown, it includes, arranged in order from top to bottom: a conductive layer 1 , a sensitive layer 2 and a flexible substrate 3 .

[0061] The conductive layer 1 is sputter-coated on the upper surface of the sensitive layer 2 . In the natural state, the structural parameters of the cracks on the surface of the conductive layer are basically the same as those of the sensitive layer.

[0062] Two electrodes (the first electrode 4 and the second electrode 5 ) are arranged on the conductive layer 1 , and an enameled wire 6 is respectively led out from the two electrodes for collecting electric signals.

[0063] The two electrodes do not touch each other. Preferably, the first electrode 4 is located at one end of the strain sensor, and the second electrode 5 is located at the other end of the strain sensor, so as to maximize the crack working area between the two electrodes.

[...

Embodiment 2

[0071] This embodiment provides a method for preparing a resistive flexible strain sensor based on drying-mediated self-assembly. Specifically, the method includes the following steps:

[0072] S1. Prepare an aqueous dispersion of acrylic resin colloid.

[0073] In this example, the parallel crack arrays were prepared by utilizing the film thickness gradient formed by the colloidal dispersion under the action of gravity flow, using the instrument-free scalable technique.

[0074] Specifically, step S1 includes:

[0075] S101, adding an aqueous acrylic resin with a particle diameter of 40-80 nm to deionized water to obtain an aqueous acrylic resin dispersion with a concentration of 0.3 g / mL.

[0076] S102, ultrasonically vibrate the prepared aqueous acrylic resin dispersion for 30 minutes, and then filter to obtain a filtrate.

[0077] S103. Store the filtered filtrate in a sealed bottle, and let it stand overnight to obtain an acrylic resin colloidal dispersion.

[0078] S2...

Embodiment 3

[0093] This embodiment also provides another method for preparing a resistive flexible strain sensor based on drying-mediated self-assembly. Specifically, the method includes the following steps:

[0094] S1. Preparation of polystyrene colloid.

[0095] In this example, the parallel crack arrays were prepared by utilizing the film thickness gradient formed by the colloidal dispersion under the action of gravity flow, using the instrument-free scalable technique.

[0096] Specifically, step S1 includes:

[0097] S101. Add polystyrene latex particles with a particle diameter of 50 nm to deionized water to obtain an aqueous dispersion of polystyrene colloidal particles with a concentration of 0.1 g / mL.

[0098] S102, ultrasonically vibrate the prepared aqueous dispersion of polystyrene colloidal particles for 30 minutes, and then filter to obtain a filtrate.

[0099] S103. Store the filtered filtrate in a sealed bottle, and let it stand overnight to obtain a polystyrene colloid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com