Method and device for quasi-distributed multi-parameter measurement of fiber bragg grating F-P cavity array

A fiber grating and quasi-distributed technology, which is applied in the field of quasi-distributed multi-parameter measurement of fiber grating F-P cavity arrays, can solve problems such as difficult large-scale preparation, complex sensor structure, and difficulty in forming sensor arrays.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

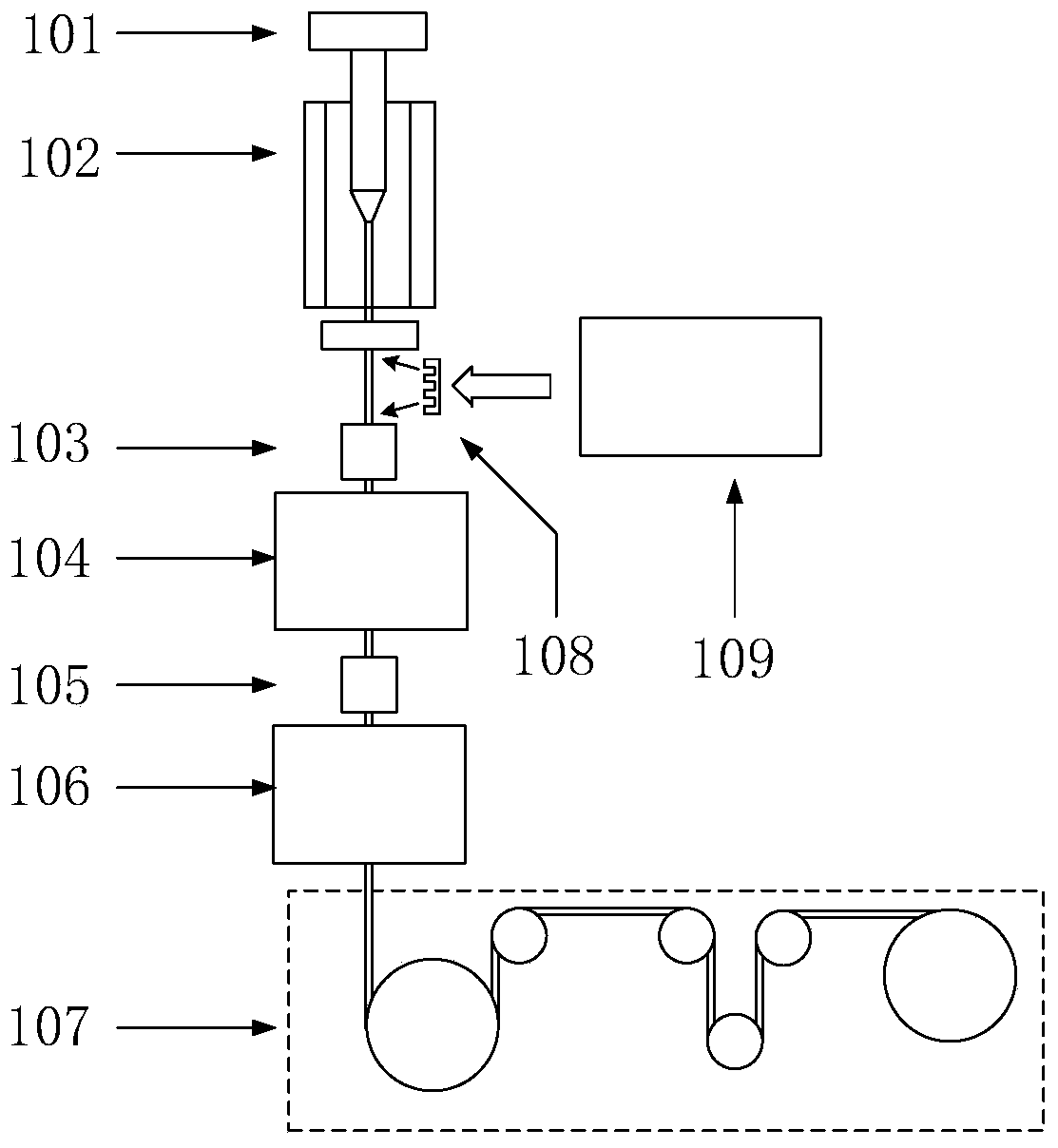

[0034] In the embodiment of the present invention, such as figure 1As shown, the preform is drawn into an optical fiber through a graphite furnace. Before the optical fiber is coated with a coating, a fiber grating F-P cavity is written in the fiber core by a phase mask method. The fiber grating F-P cavity emits two laser pulses continuously by controlling the laser 109 . The laser pulse trigger time interval controls the fiber grating F-P cavity. The F-P cavity interval of the fiber grating is related to the rotation distance of the optical fiber through the active pulley. The laser pulse passes through the phase mask 108 to form interference fringes in the fiber core, thereby writing the grating. After the fiber grating F-P cavity is written, the fiber coating device 103 starts according to the distance the fiber passes through the driving pulley. According to the start-up time of the optical fiber coating device, the coating length and thickness of the special coating m...

Embodiment 2

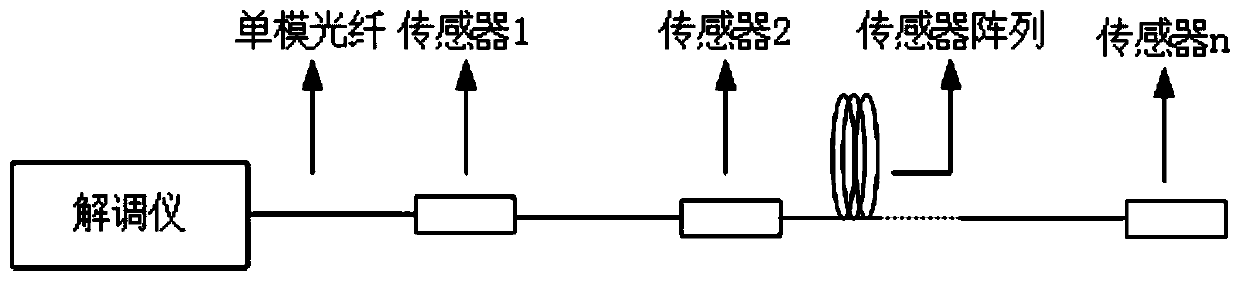

[0043] In this embodiment, the light source, circulator, fiber grating F-P cavity sensor array, and demodulator in the device for quasi-distributed multi-parameter measurement of the fiber grating F-P cavity array are connected in sequence, and the light emitted from the light source is incident on the fiber grating through the circulator In the F-P cavity sensor array, it is reflected back to the circulator, and finally enters the demodulator; two fiber gratings form a Fabry-Perot interferometer, and the surface of the grating is coated with different coating materials. Make the sensor form F-P cavity interference peak and grating reflection peak under the action to be measured. Under the change of external parameters, different regions of the fiber grating F-P cavity have different resonance peaks. According to the movement of the resonant peak wavelength, the change of the external environment parameter is measured.

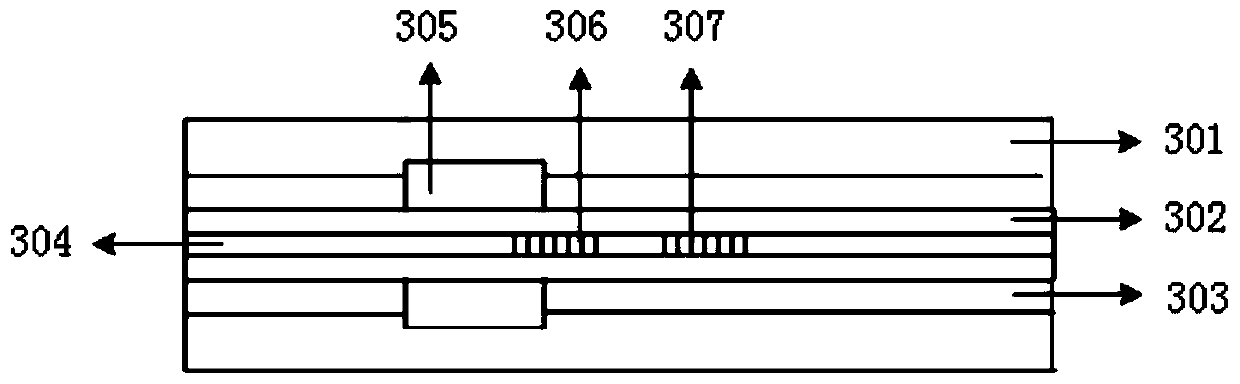

[0044] Such as Figure 4 As shown, the surface of the ...

Embodiment 3

[0050] A method for quasi-distributed multi-parameter measurement of a fiber grating F-P cavity array is provided, which is characterized in that the method includes the following steps, step 1, coating different coating materials on the surface of the grating; The fiber grating F-P cavity sensor array and the demodulator are connected in sequence, and the light emitted from the broadband light source enters the fiber grating F-P cavity sensor array through the circulator, and then reflects back to the circulator; step 3, finally enters the demodulator; using two A fiber grating constitutes a Fabry-Perot interferometer (Fabry-Perot interferometer). The fiber grating F-P cavity sensor forms an F-P cavity interference peak and a grating reflection peak under the action of the parameters to be measured. When the parameters to be measured change, according to the resonant peak wavelength Change the difference of the value, combine with the sensitivity matrix equation, and measure a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com