Capacitive sound pressure hydrophone based on MEMS technology and preparation method thereof

A capacitive and hydrophone technology, applied in the field of MEMS, can solve the problems of affecting the sensitivity of the sensor, unfavorable underwater sound pressure measurement, and the resistivity will also change, so as to achieve the effect of improving sensitivity, balancing internal and external pressure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the present invention, the present invention will be further clearly and completely described below in conjunction with reference to the accompanying drawings and in conjunction with embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

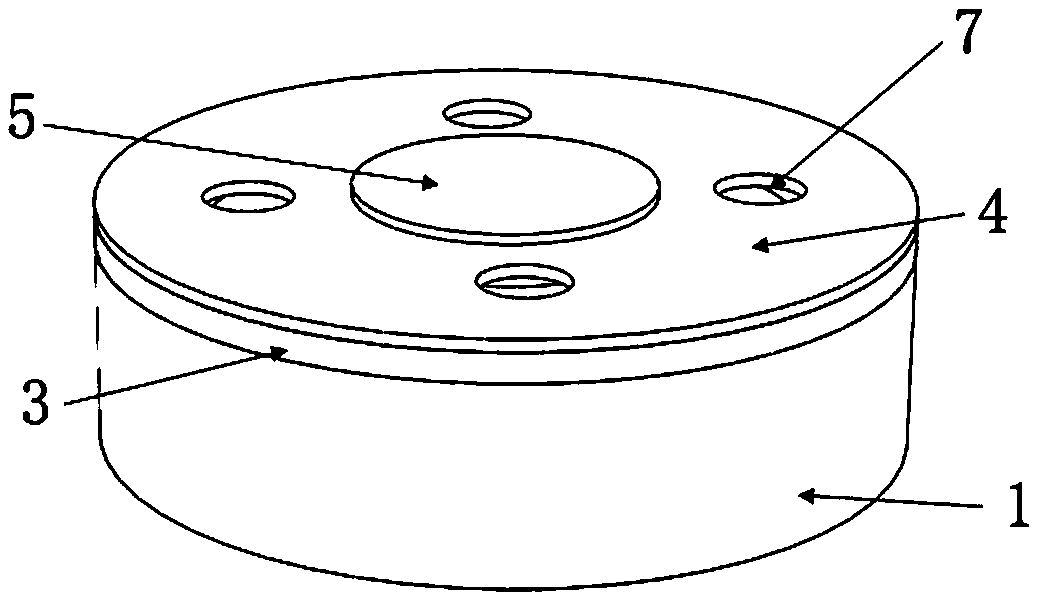

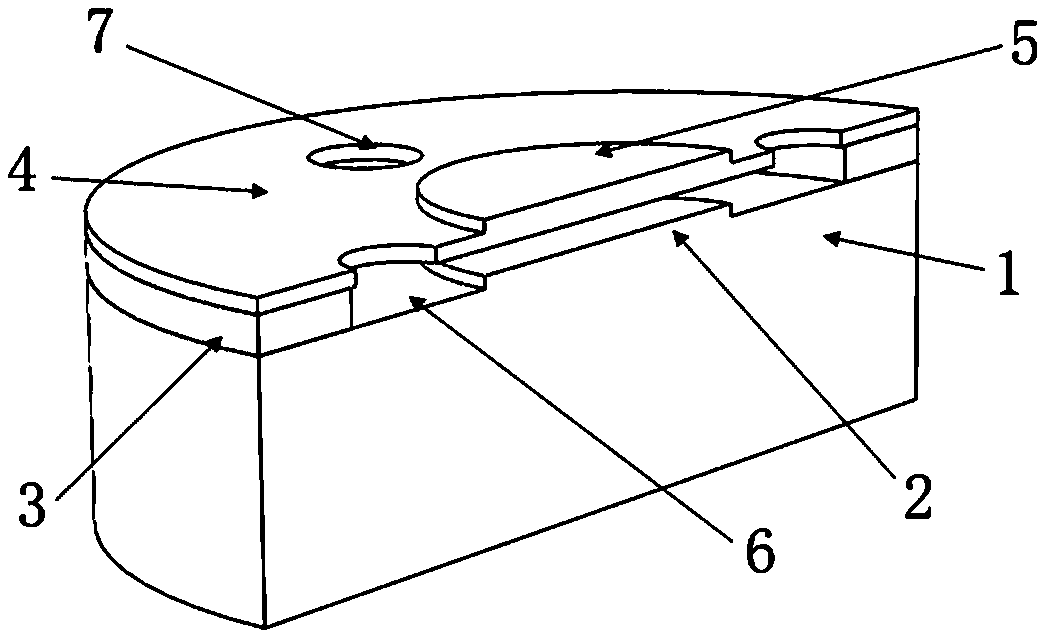

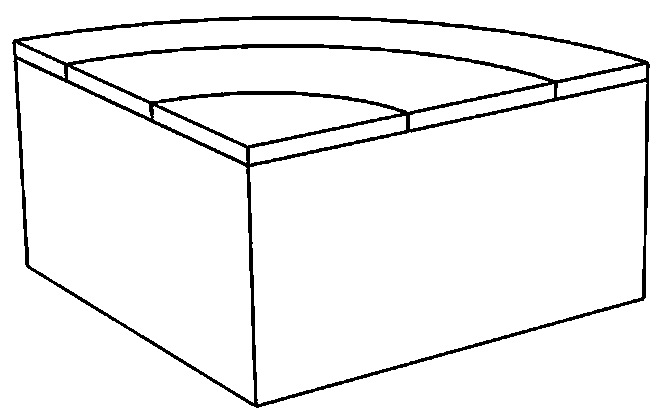

[0031] Such as figure 1 , 2 Shown, a kind of capacitive sound pressure hydrophone based on MEMS technology comprises a glass substrate 1, and the center of the top surface of the glass substrate 1 is provided with a disc-shaped metal aluminum lower electrode 2; the top of the glass substrate 1 Also be provided with annular silicon pillar 3 on the surface, the inner ring of annular silicon pillar 3 is annular and its diameter is twice of the diameter of disc-shaped metal aluminum lower electrode 2, and the height of annular silicon pillar 3 is higher...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com