Cigarette perforated tipping paper hole detector

A tipping paper and detector technology, which is applied in the direction of using optical devices, instruments, measuring devices, etc., can solve the problem of inability to non-destructively measure the hole size of punched cigarettes in online tipping paper, and achieve simple structure, good reproducibility, Easy to maintain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

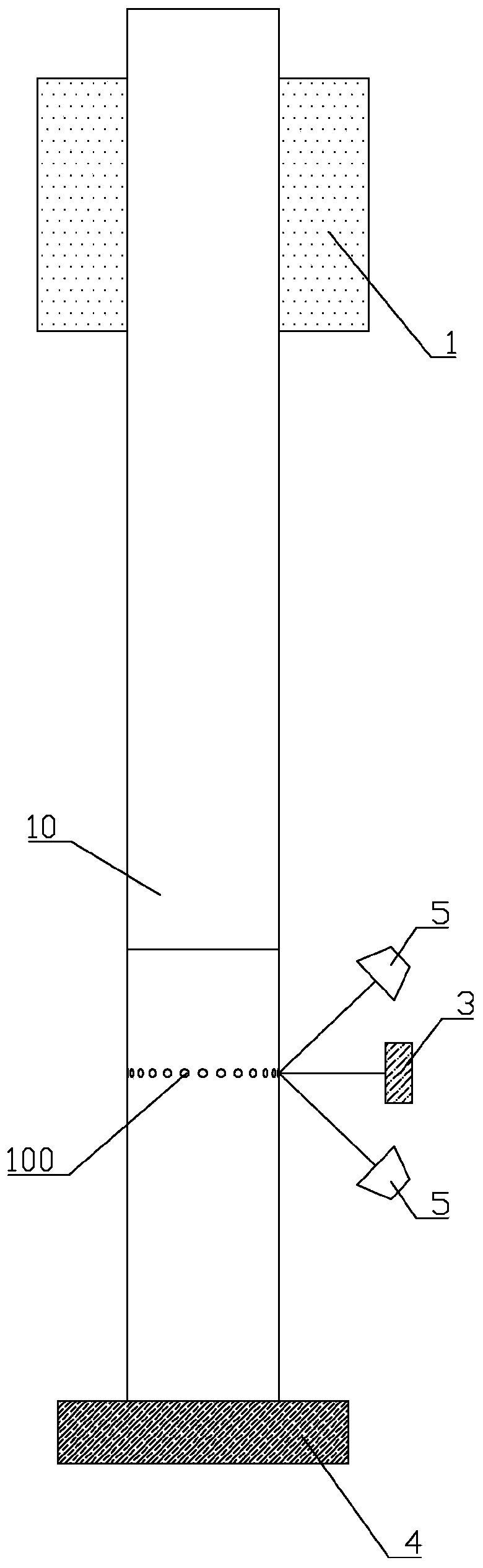

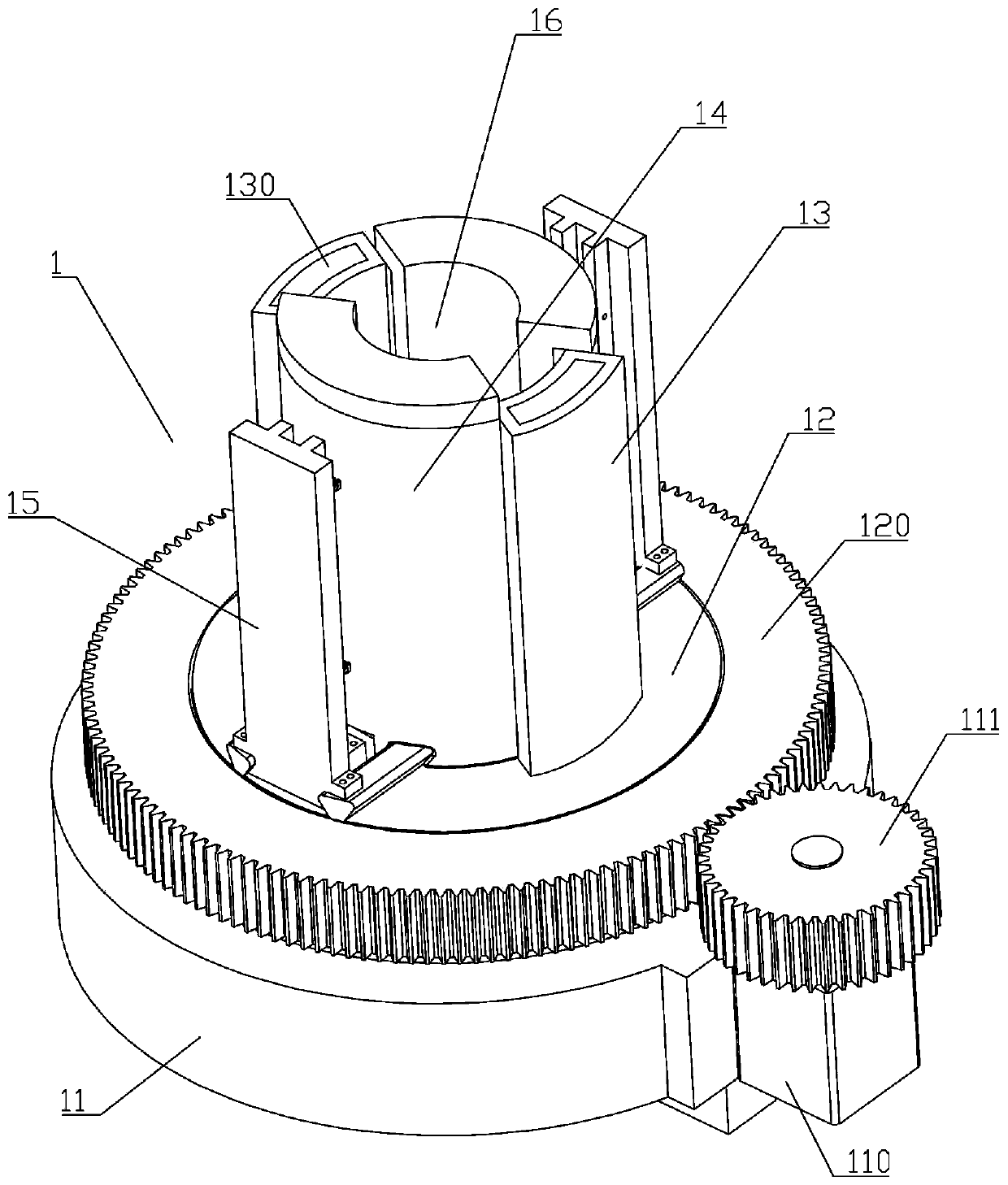

[0041] Such as figure 1 with Figure 3-Figure 8 As shown, a hole detector for perforated tipping paper for cigarettes in this embodiment includes a detection system and a data processing system.

[0042] The cigarette 10 is clamped and fixed by the rotating holder 1. The detection system is used to detect and obtain the image information of the hole 100 on the tipping paper of the complete cigarette 10. The image of the hole 100 here is the image formed by the rotation of the complete cigarette 10 in one circle. , The hole image includes intuitive information such as the number of holes, the number of rows of holes, the width of the holes, the shape of the holes, etc., and the cigarette is rotated by the rotating holder to collect the hole information comprehensively.

[0043] The detection system includes a rotating holder 1 , an imaging mechanism 3 , a movable chassis 4 and a light source 5 .

[0044] Wherein, the rotating holder 1 is used to clamp and fix the cigarette 10...

Embodiment 2

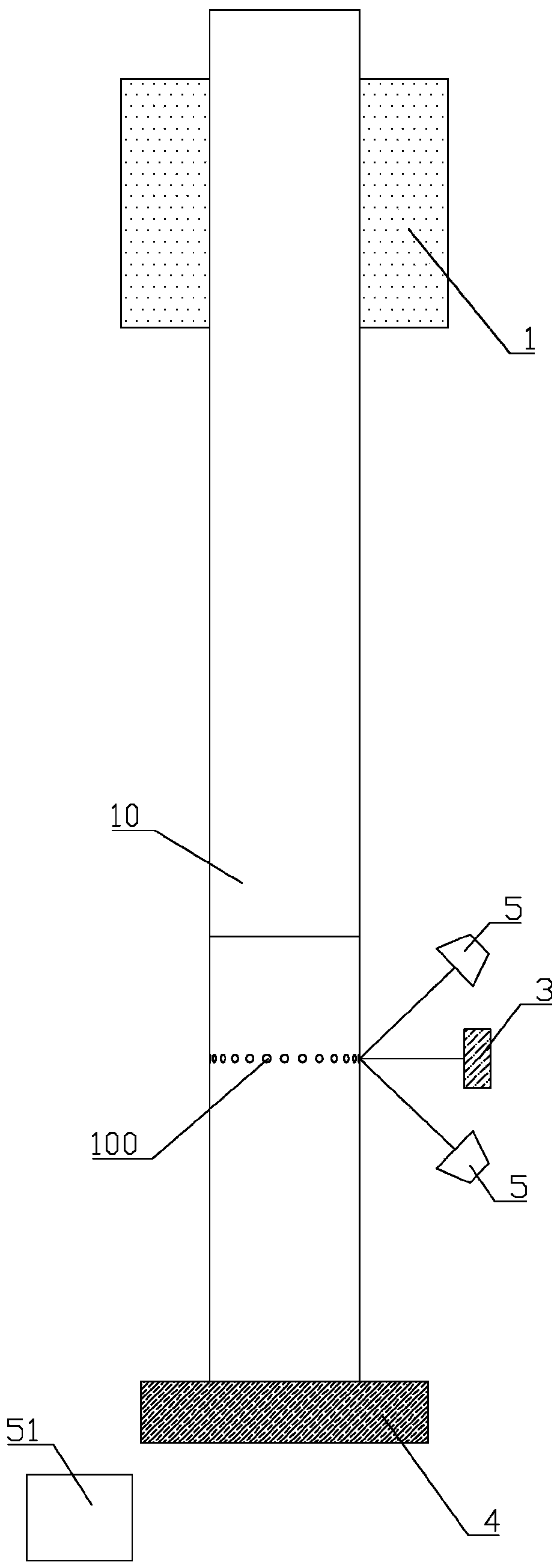

[0059] The differences between this embodiment and Embodiment 1 are:

[0060] Such as figure 2 As shown, the motion track of the movable chassis 4 is to move up and down, and a lateral push mechanism 51 is also provided at the bottom of the movable chassis 4 sides, and the lateral push mechanism 51 can adopt a cylinder to push horizontally, which has a simple structure and is easy to operate.

[0061] With such a structural design, after rotating the holder 1 to loosen the cigarette holder 10, the movable chassis 4 does not move to one side, but moves downward, so that the cigarette holder 10 can be dropped from the movable chassis 4 for reuse. The lateral pushing mechanism 51 pushes away the cigarettes falling from the rotary holder 1, and then the movable chassis 4 is reset, so that the next round of cigarettes 10 detection can be carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com