White light LED excited by ultraviolet and preparation method thereof

An LED chip, white light technology, applied in the field of white light LED, can solve the problems of enhanced full emission effect at the interface, easy aging and yellowing, and large difference in refractive index between air and glass interface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

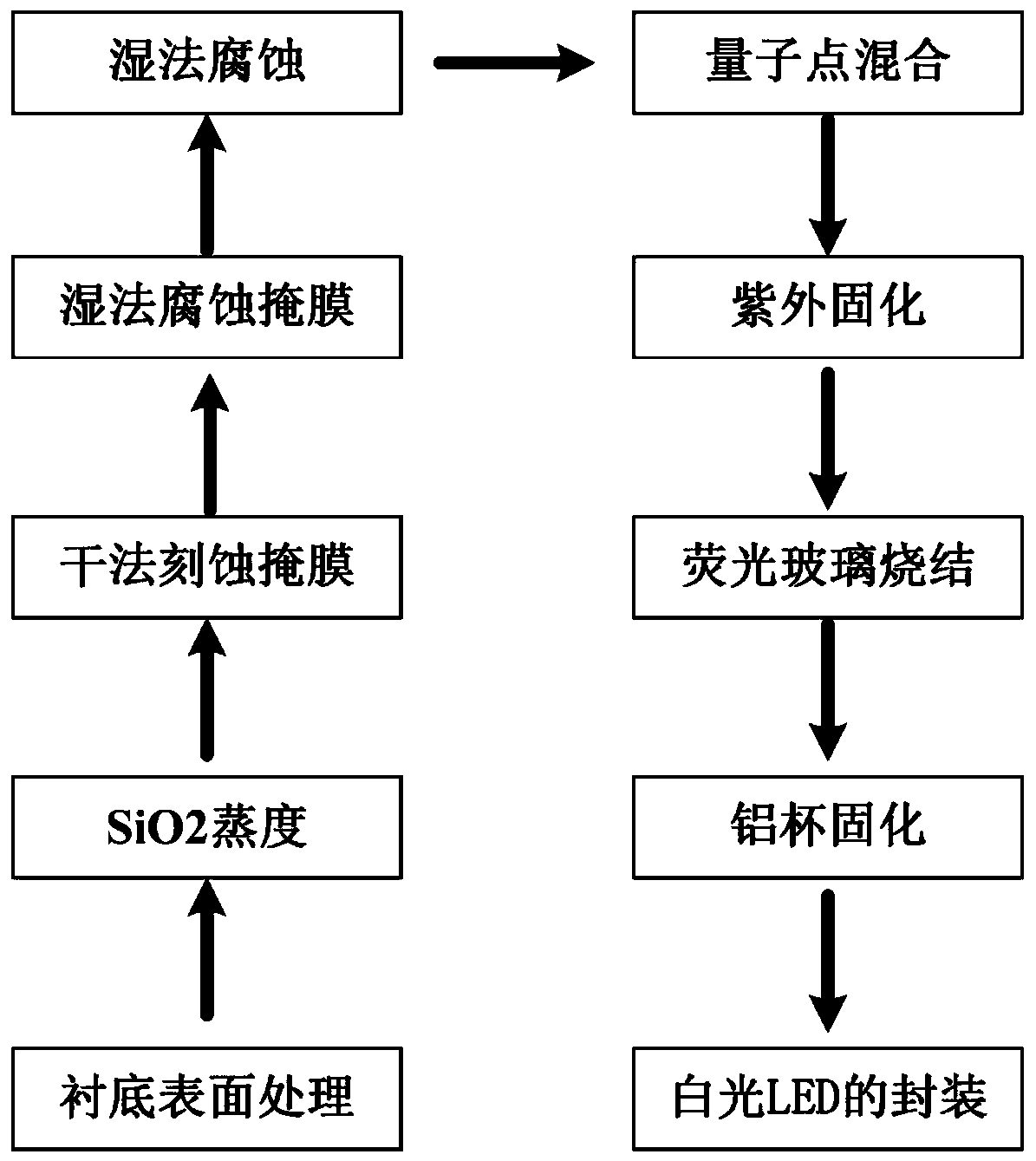

[0008] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

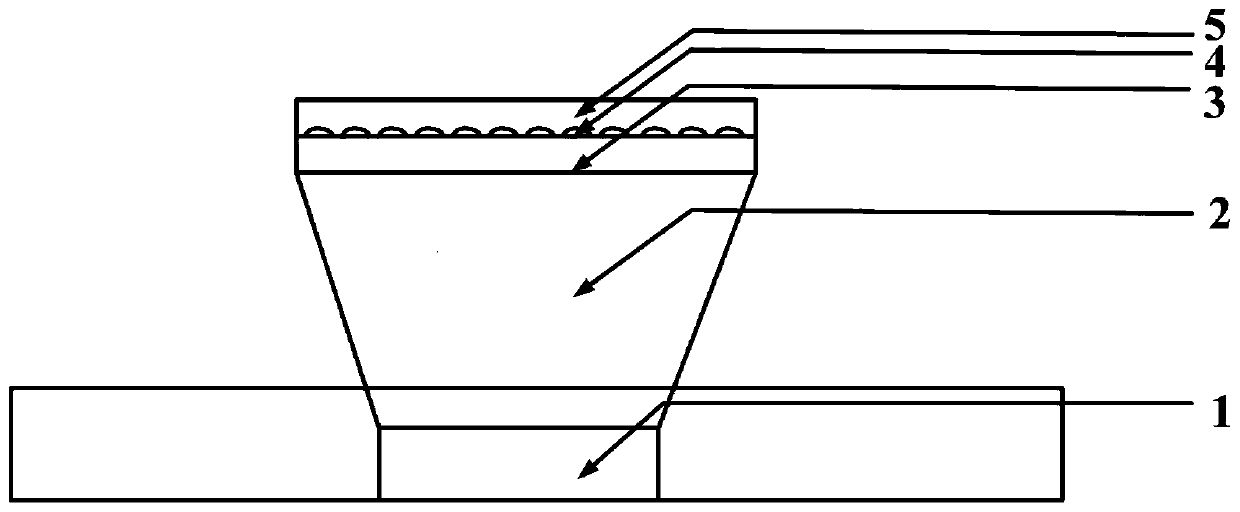

[0009] Such as figure 1 As shown, the present invention provides a white light LED that adopts ultraviolet excitation, including an ultraviolet LED chip 1, a green fluorescent glass 3, and a nano-patterned substrate coated with red quantum dots arranged in sequence, and the green fluorescent glass is arranged on the Above the light-emitting surface of the ultraviolet LED chip, the nano-patterned substrate coated with red quantum dots is arranged on the green fluorescent glass.

[0010] Ultraviolet LED chips are used to excite green fluorescent glass and red quantum dots to obtain white light, so that the generated spectrum contains both green and red light components. In addition, quantum dots have a higher color rendering index than phosphors, so It can significantly improve the color rendering index of white LEDs; the use of green fluorescent glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com