Method for cutting a workpiece using a laser beam

A workpiece, laser technology, used in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as damage to cutting contours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

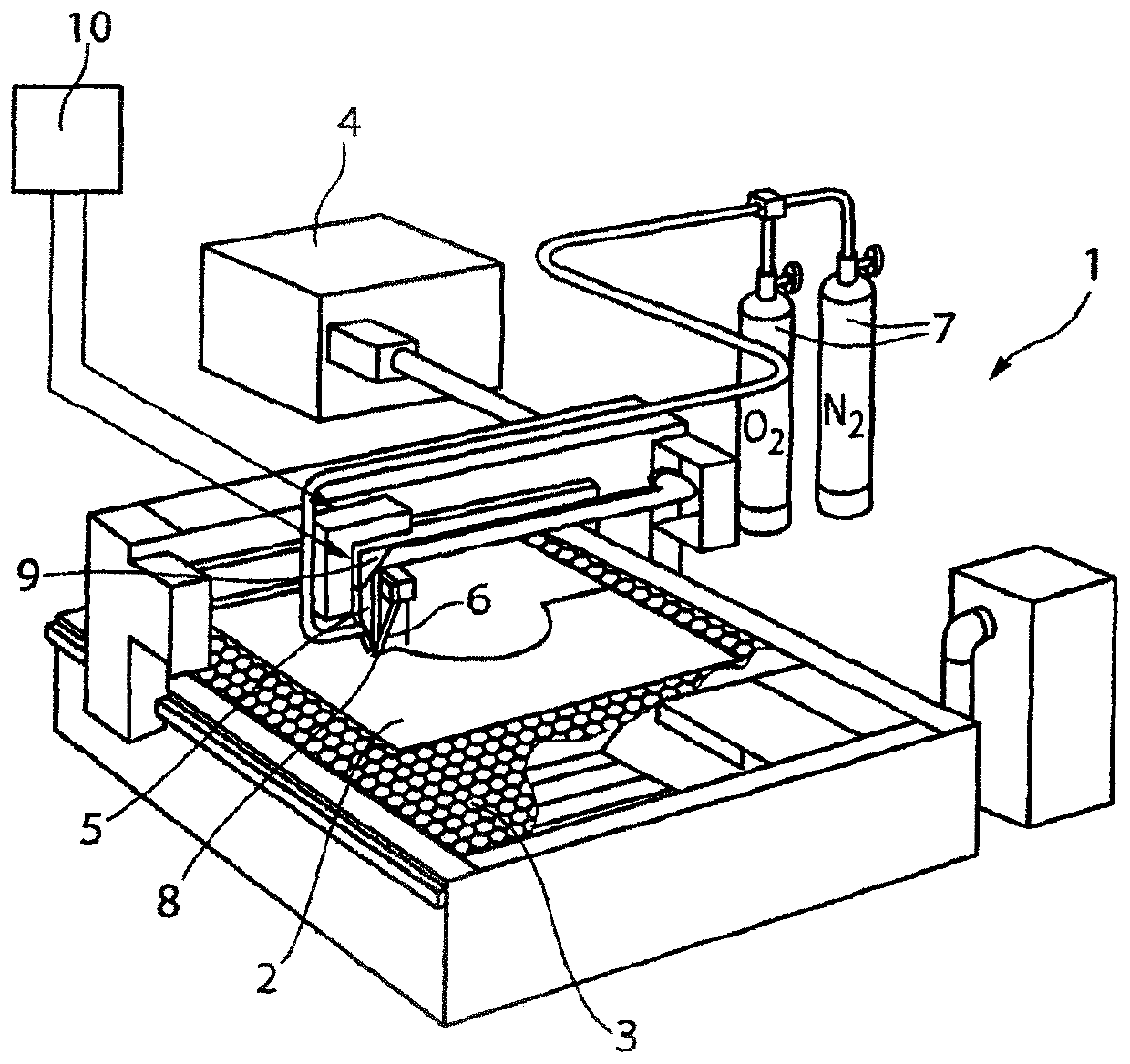

[0033] figure 1 A laser cutting machine 1 is shown for laser cutting a workpiece 2 which is arranged on a workpiece support 3 . The laser cutting machine 1 has a laser beam generator 4 which is designed as a diode laser in the exemplary embodiment. In an alternative embodiment it is provided that the laser beam generator 4 is designed as a CO 2 lasers or solid-state lasers. Additionally, from figure 1 The cutting head 5 can be seen in . A laser beam 6 is generated in the laser beam generator 4 , which is guided from the laser beam generator 4 to the cutting head 5 by means of a light guide or deflection mirror. Laser beam 6 is directed onto workpiece 2 by means of focusing optics arranged in cutting head 5 .

[0034]Furthermore, the laser cutting machine 1 is supplied with cutting gases 7 , in this embodiment oxygen and nitrogen. The cutting gas 7 enters a nozzle (cutting gas nozzle) 8 of the cutting head 5 from which it emerges together with the laser beam 6 . Furtherm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com