A kind of anti-skid liquid lubrication simulated ice board

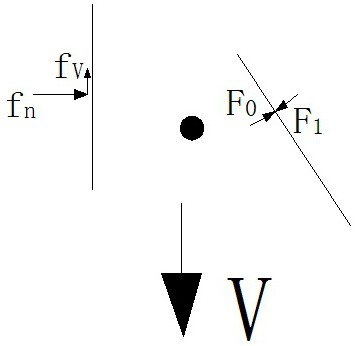

A liquid lubrication and anti-skid technology, which is applied in skating, water skiing, binding of skis, etc., can solve the problems of smooth sliding on real ice and high friction coefficient, so as to improve sliding smoothness and expand laying area, the effect of slowing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

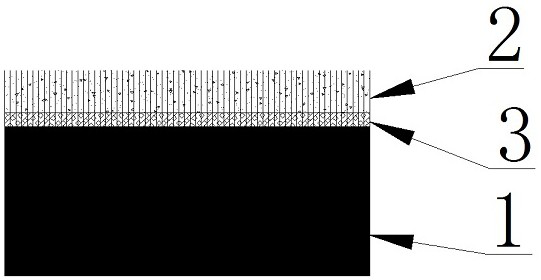

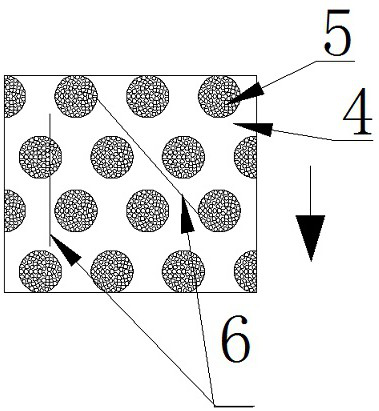

Embodiment 1

[0029] Mix ultra-high molecular weight polyethylene fiber bundles with low-friction high-density polyethylene sheets or filaments in a certain proportion, heat and press to form a whole, cut into thin slices with a certain thickness, and use flame baking on the lower surface of the thin slices to make the ultra-high High-molecular-weight polyethylene bonds more strongly to high-density polyethylene materials. The lower surface of the sheet and the main body of the simulated ice board are bonded as a whole by hot melt adhesive, and then the surface machining can be carried out. Lay the processed simulated ice slab on the field, and spray lubricating fluid on the surface of the simulated ice slab.

Embodiment 2

[0031] Mix aramid fiber bundles with low-friction high-density polyethylene sheets or filaments in a certain proportion, heat and press to form a whole, use a cutting saw to cut into thin slices with a certain thickness, and use flame baking on the lower surface of the thin slices to make the aromatic fibers The bond between the fiber bundle and the high-density polyethylene material is stronger. The lower surface of the sheet and the main body of the simulated ice board are bonded as a whole by hot melt adhesive, and then the surface machining can be carried out. Lay the processed simulated ice slab on the field, and spray lubricating fluid on the surface of the simulated ice slab.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com