Multilayer centrifugal granulator for efficiently treating large-flow liquid slag

A technology of liquid slag and granulator, which is applied in the direction of liquid separation into beads and granulation, granulation in rotating disk/pot, recycling technology, etc., which can solve the problem of limited space, reducing the floor area of granulation bin array, Increase the granulation bin and other issues to achieve the effect of expanding the scope, increasing the overall spreading area, and inhibiting slagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with test examples and specific embodiments. However, it should not be understood that the scope of the above subject matter of the present invention is limited to the following embodiments, and all technologies realized based on the content of the present invention belong to the scope of the present invention.

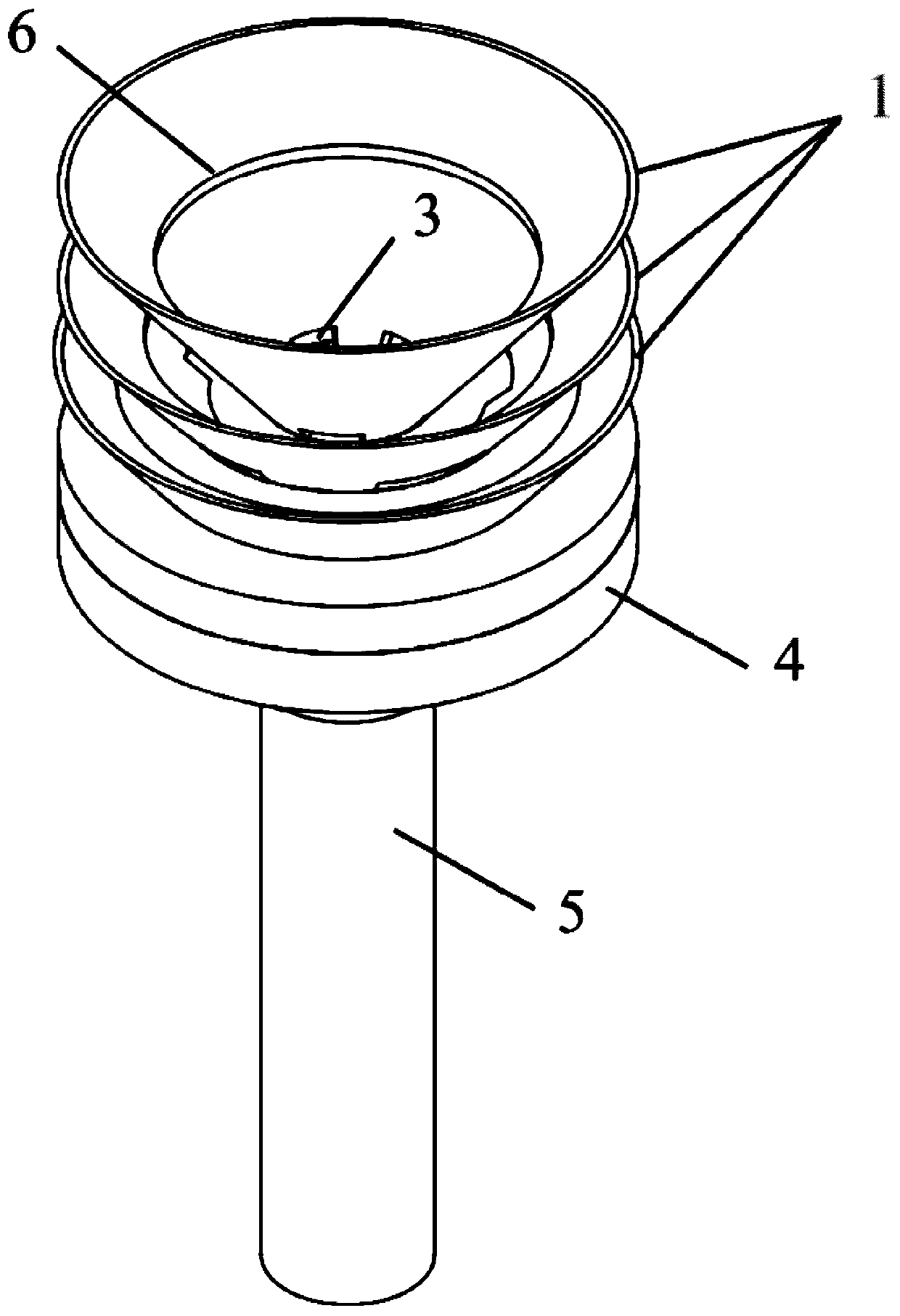

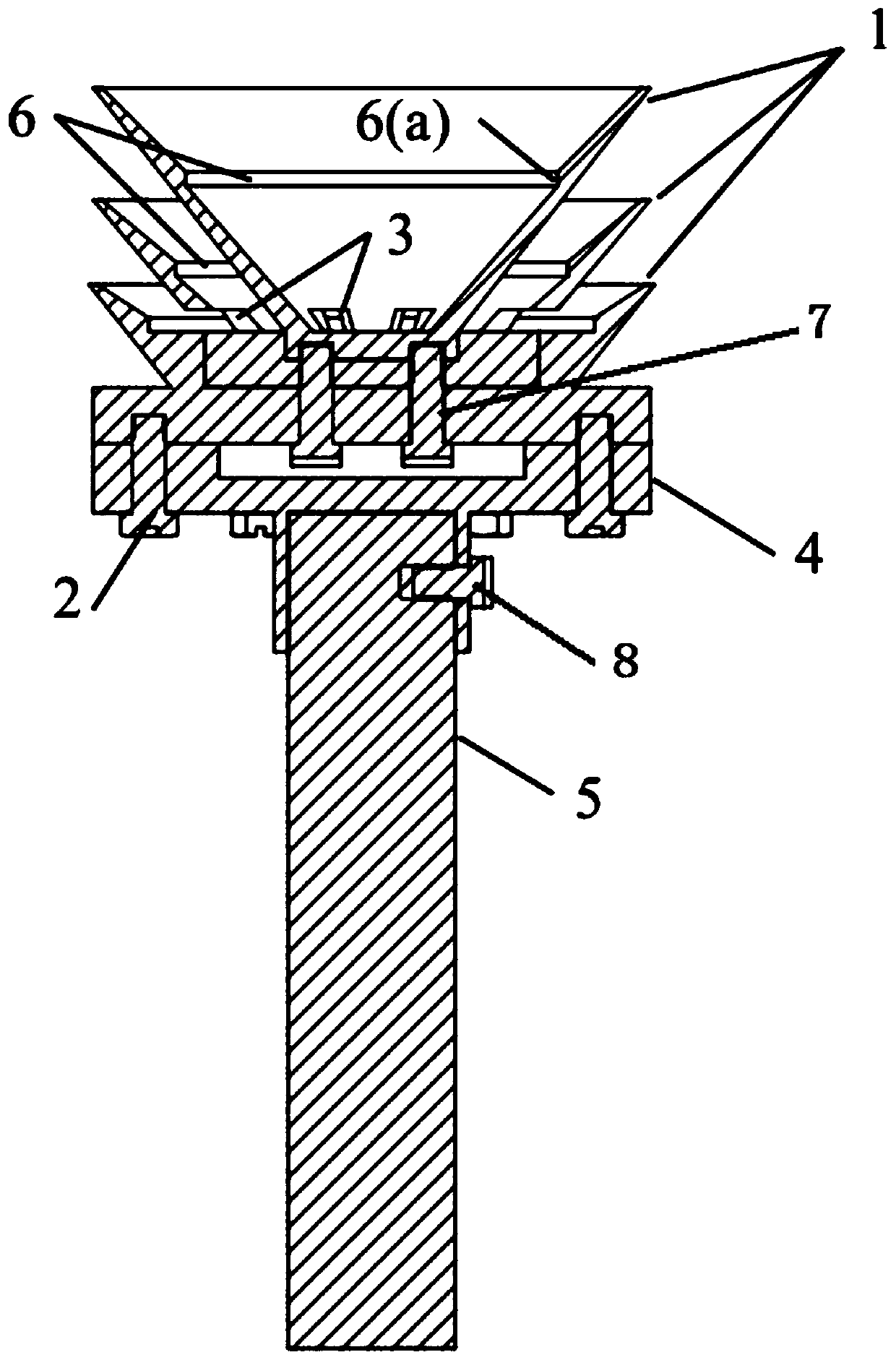

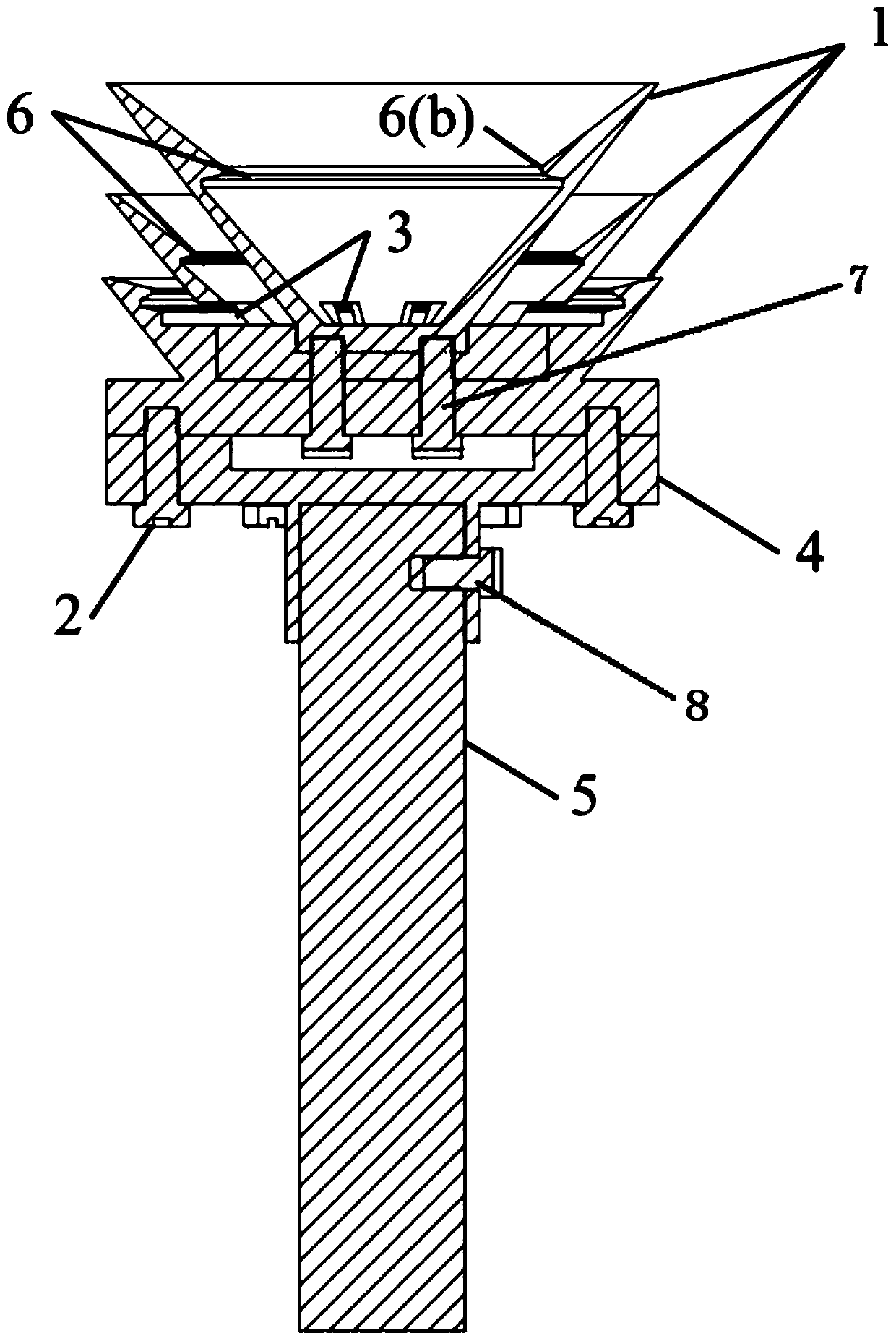

[0018] see Figure 1 to Figure 4 , a multi-layer centrifugal granulator for efficiently processing large-flow liquid slag, including a granulator main body 1, a tray 4 and a rotating shaft 5, the tray 4 is fixed on the top of the rotating shaft 5; the granulator main body 1 is connected by bolts 2 fixed on the tray 4; the tray 4 is driven by the rotating shaft 5 to drive the rotation of the main body of the granulator; the main body of the granulator 1 is composed of several granulation units stacked along the height direction; all the granulation units are coaxially arranged; The d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com