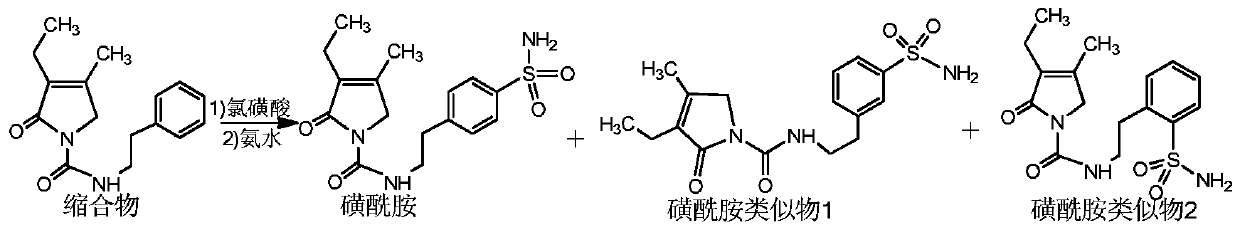

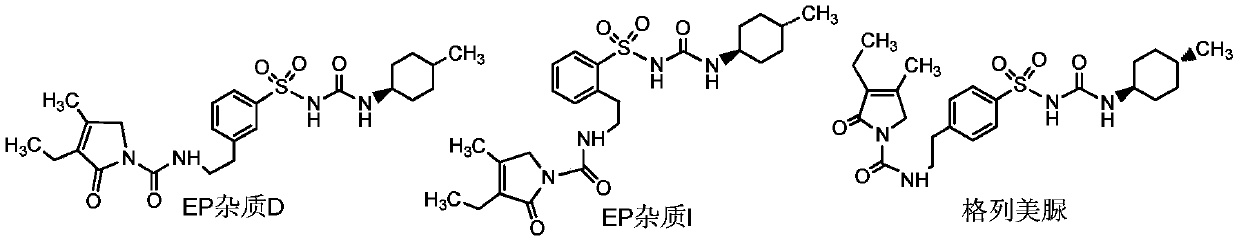

Preparation method of glimepiride intermediate sulfonamides analogue 1 and the sulfonamide analogue 2

A technology for sulfonamides and analogs, which is applied in the field of preparation of sulfonamide analog 1 and sulfonamide analog 2, the key intermediates of glimepiride, can solve problems such as no literature reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

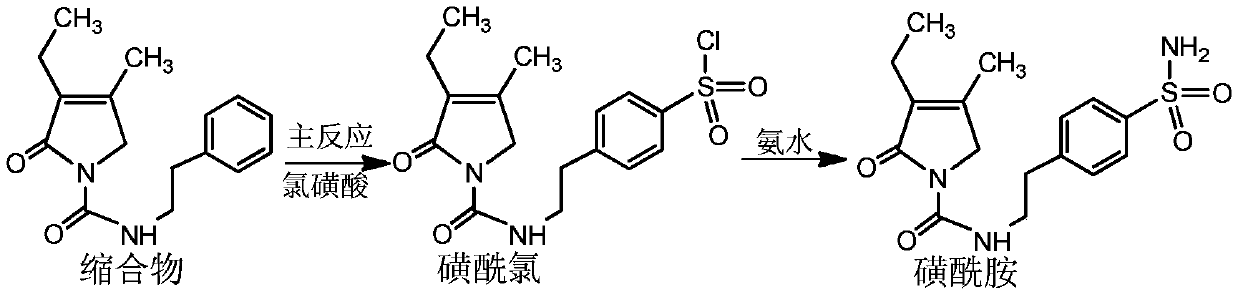

Method used

Image

Examples

Embodiment 1

[0032] Add 150g of chlorosulfonic acid to a 250ml reaction bottle, cool down to below 20°C, slowly add 30g of condensate at 10-20°C, then raise the temperature to 35°C, and react at 35±2°C for 5 hours. After the reaction was completed, the reaction solution was slowly poured into 1000 ml of ice water. Then filter and wash with water to obtain a white solid.

[0033] Add the white solid to a 100ml reaction flask, add 800ml of concentrated ammonia water, react at 20-25°C for 4 hours, then raise the temperature to 40±2°C, and continue the reaction for 4 hours. After the reaction, the temperature was lowered to below 25°C, filtered and washed with water to obtain a white solid.

[0034] Finally, the white solid was preparatively chromatographed by HPLC, chromatographic conditions: chromatographic column: C18, 300*50.0mm, particle size 10μm, pore size 120A, wavelength: 225nm, mobile phase A: methanol, mobile phase B: water, isocratic washing A 80% and B 20% (V / V) were separated t...

Embodiment 2

[0036] Add 180g of chlorosulfonic acid into a 250ml reaction bottle, cool down to below 20°C, slowly add 30g of condensate at 10-20°C, then raise the temperature to 40°C, and react at 40±2°C for 7 hours. After the reaction was completed, the reaction solution was slowly poured into 1000 ml of ice water. Then filter and wash with water to obtain a white solid.

[0037] Add the white solid to a 100ml reaction flask, add 800ml of concentrated ammonia water, react at 20-25°C for 4 hours, then raise the temperature to 40±2°C, and continue the reaction for 4 hours. After the reaction, the temperature was lowered to below 25°C, filtered and washed with water to obtain a white solid.

[0038] Finally, the white solid was preparatively chromatographed by HPLC, chromatographic conditions: chromatographic column: C18, 300*50.0mm, particle size 10μm, pore size 120A, wavelength: 225nm, mobile phase A: methanol, mobile phase B: water, isocratic washing A 80% and B 20% (V / V) were separated...

Embodiment 3

[0040] Add 300g of chlorosulfonic acid into a 250ml reaction bottle, cool down to below 20°C, slowly add 30g of condensate at 10-20°C, then raise the temperature to 50°C, and react at 50±2°C for 8 hours. After the reaction was completed, the reaction solution was slowly poured into 1000 ml of ice water. Then filter and wash with water to obtain a white solid.

[0041] Add the white solid to a 100ml reaction flask, add 800ml of concentrated ammonia water, react at 20-25°C for 4 hours, then raise the temperature to 40±2°C, and continue the reaction for 4 hours. After the reaction, the temperature was lowered to below 25°C, filtered and washed with water to obtain a white solid.

[0042] Finally, the white solid was preparatively chromatographed by HPLC, chromatographic conditions: chromatographic column: C18, 300*50.0mm, particle size 10μm, pore size 120A, wavelength: 225nm, mobile phase A: methanol, mobile phase B: water, isocratic washing A 80% and B 20% (V / V) were separated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com