Polyethylene terephthalate composite material, product and preparation method

A technology of polyethylene terephthalate and ethylene glycol phthalate, which is applied in the field of material processing, can solve the problems of reducing the mechanical properties of PET materials, complicating the overall process flow, and complicating the process flow, so as to achieve easy The effect of large-scale industrial production, simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

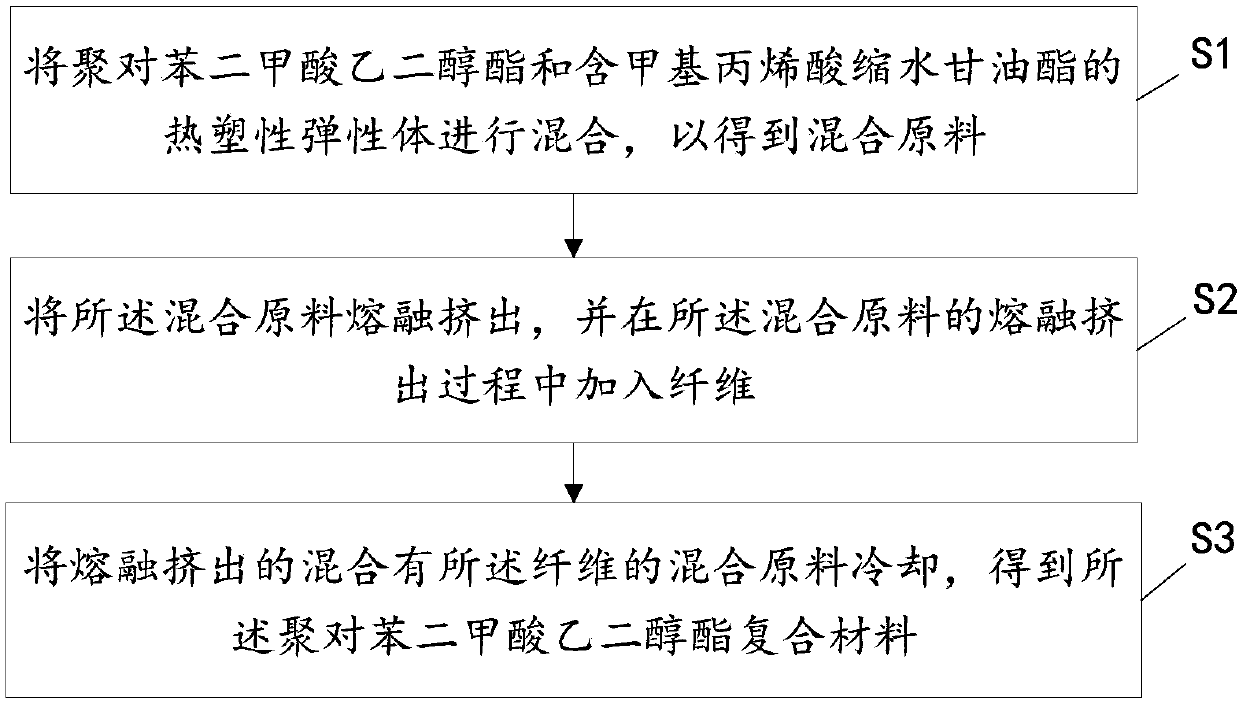

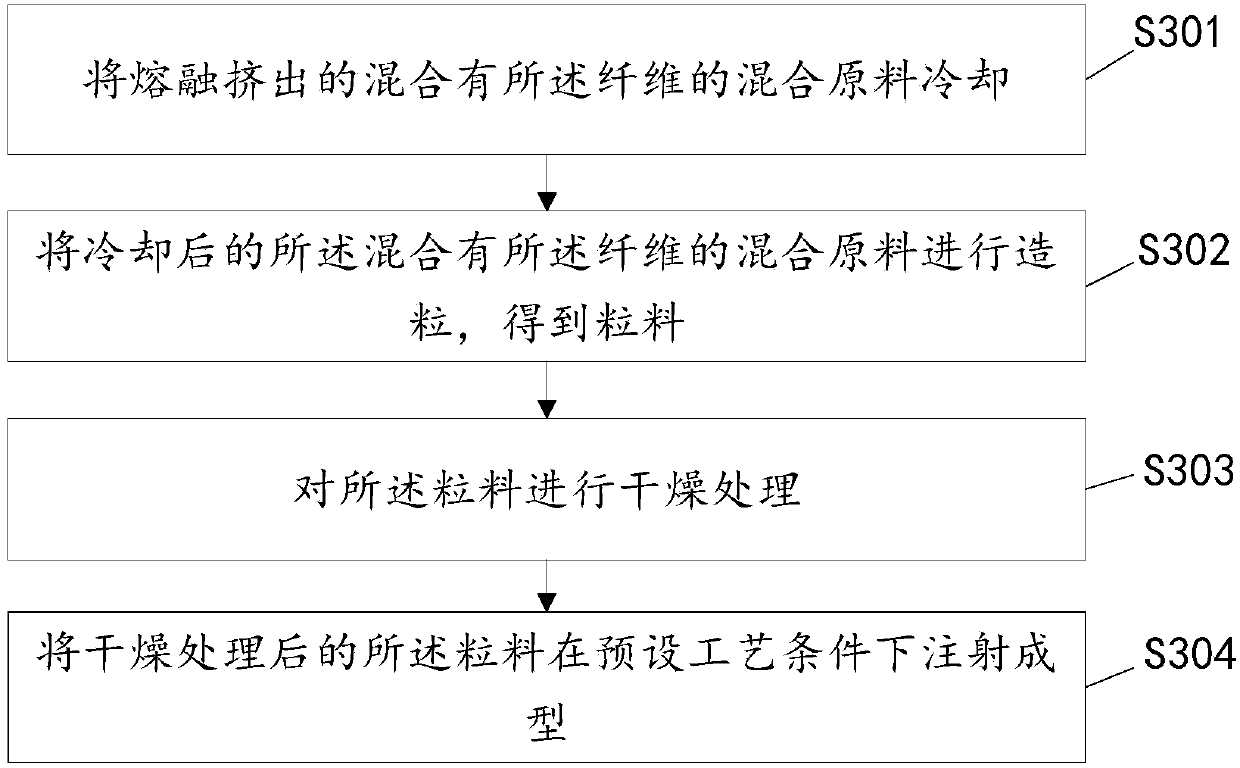

[0060] see figure 1 , figure 1 The embodiment of the present invention also provides a schematic flow chart of a preparation method. The embodiment of the present invention is used to prepare the polyethylene terephthalate composite material described in the embodiment of the present invention, including:

[0061] S1, mixing polyethylene terephthalate and a thermoplastic elastomer containing glycidyl methacrylate to obtain a mixed raw material;

[0062] S2. Melt extruding the mixed raw material, and adding fibers during the melt extrusion process of the mixed raw material;

[0063] S3, cooling the melt-extruded mixed raw material mixed with the fibers to obtain the polyethylene terephthalate composite material.

[0064] Further, mixing polyethylene terephthalate and a thermoplastic elastomer containing glycidyl methacrylate as described in step S1 includes:

[0065] Polyethylene terephthalate, thermoplastic elastomer containing glycidyl methacrylate, antioxidant and process...

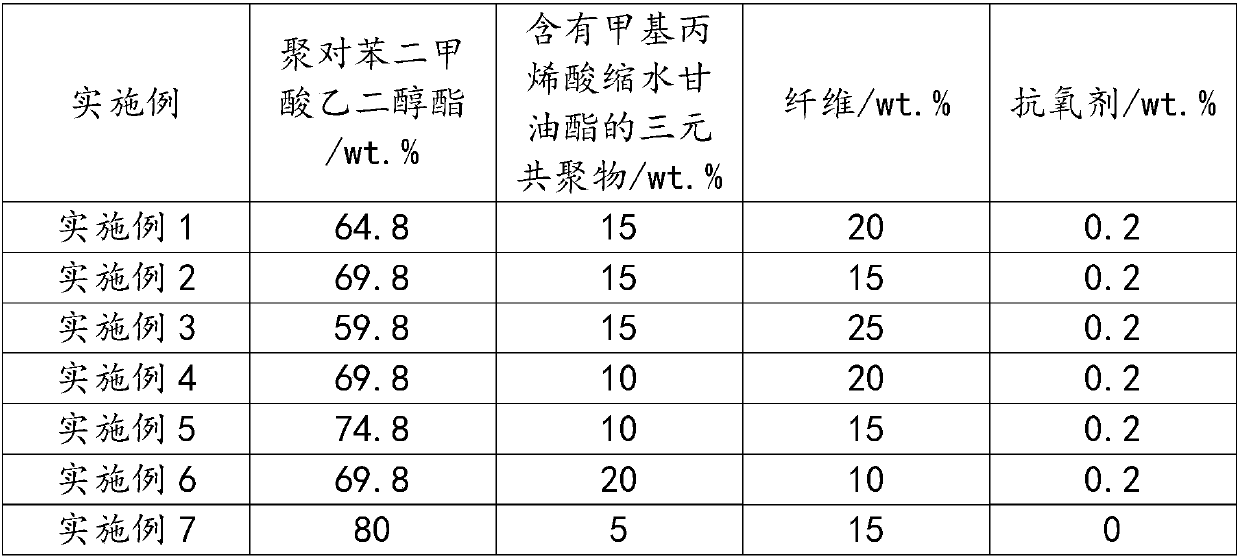

Embodiment 1

[0083] The components of the polyethylene terephthalate composite material provided in this embodiment include: a content of 64.8wt.% polyethylene terephthalate, a content of 15wt.% containing glycidyl methacrylate A thermoplastic elastomer of ester, a fiber content of 20 wt.%, and an antioxidant content of 0.2 wt.%.

[0084] The preparation process of the polyethylene terephthalate composite material provided in this example is as follows: after weighing each component of the formula, the polyethylene terephthalate is dried in a drying oven at 125°C for 5 hours , and then mix the polyethylene terephthalate and antioxidant in a high-speed mixer for 3 to 4 minutes to obtain the mixed raw material; add the mixed raw material to the feeder of the twin-screw extruder, and the fiber is fed through the side Adding at the mouth, adjusting the speed ratio of the main screw and the feeding screw, stabilizing the fiber content, making all the components melt extruded, cooled, granulated...

Embodiment 2

[0087]The components of the polyethylene terephthalate composite material provided in this embodiment include: polyethylene terephthalate with a content of 69.8wt.%, and glycidyl methacrylate with a content of 15wt.%. The thermoplastic elastomer, the fiber content is 15wt.%, and the antioxidant content is 0.2wt.%.

[0088] The preparation process of the polyethylene terephthalate composite material provided in this example is as follows: after weighing each component of the formula, the polyethylene terephthalate is dried in a drying oven at 125°C for 5 hours , and then mix the polyethylene terephthalate and antioxidant in a high-speed mixer for 3 to 4 minutes to obtain the mixed raw material; add the mixed raw material to the feeder of the twin-screw extruder, and the fiber is fed through the side Adding at the mouth, adjusting the speed ratio of the main screw and the feeding screw, stabilizing the fiber content, making all the components melt extruded, cooled, granulated, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com