Scouring-resistant slurry valve

An erosion-resistant and slurry technology, which is applied in the field of erosion-resistant slurry valves, can solve problems such as short service life, easy to be eroded, valve stuck, etc., to improve physical and chemical properties, prolong service life, and improve valve body life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

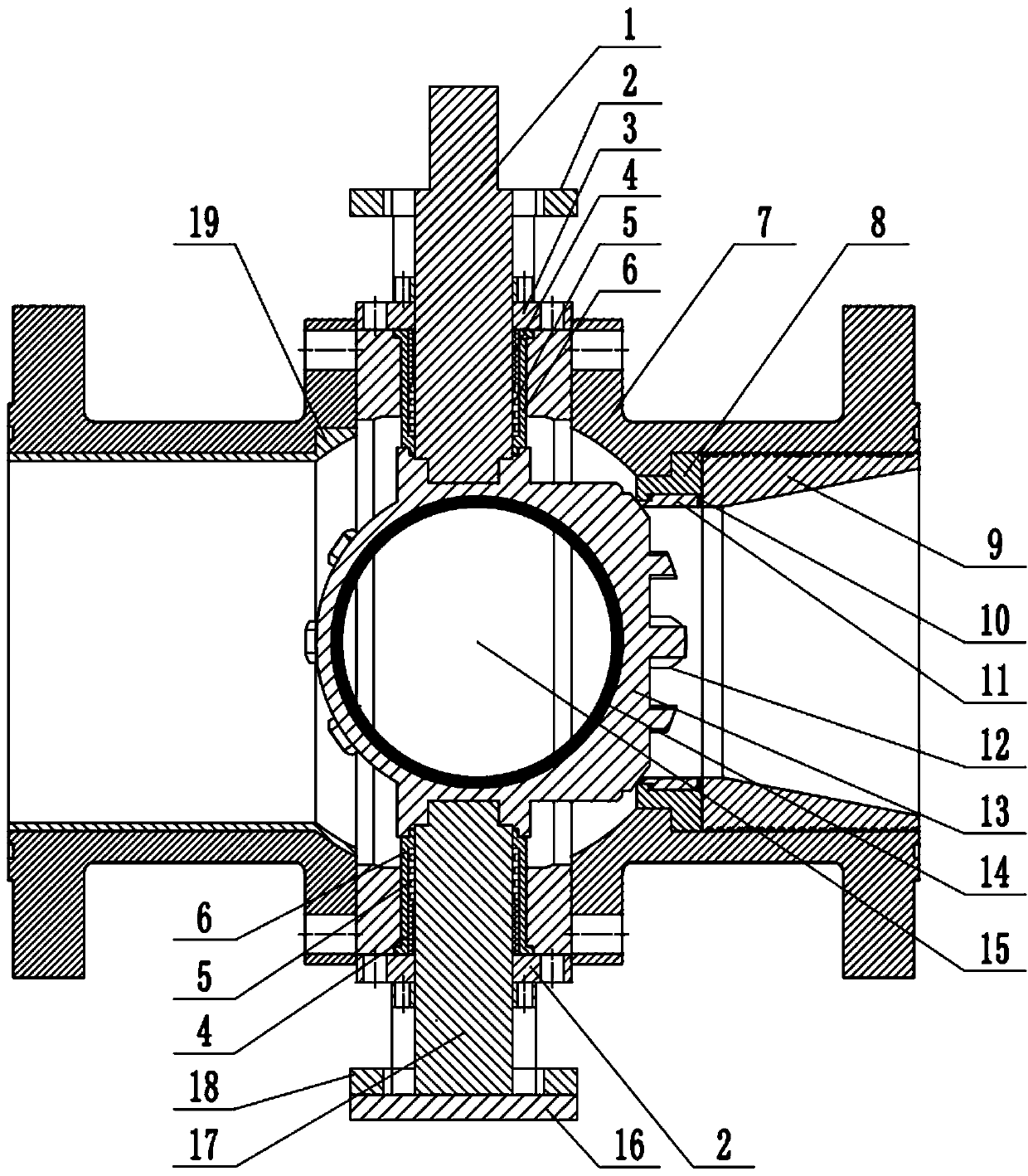

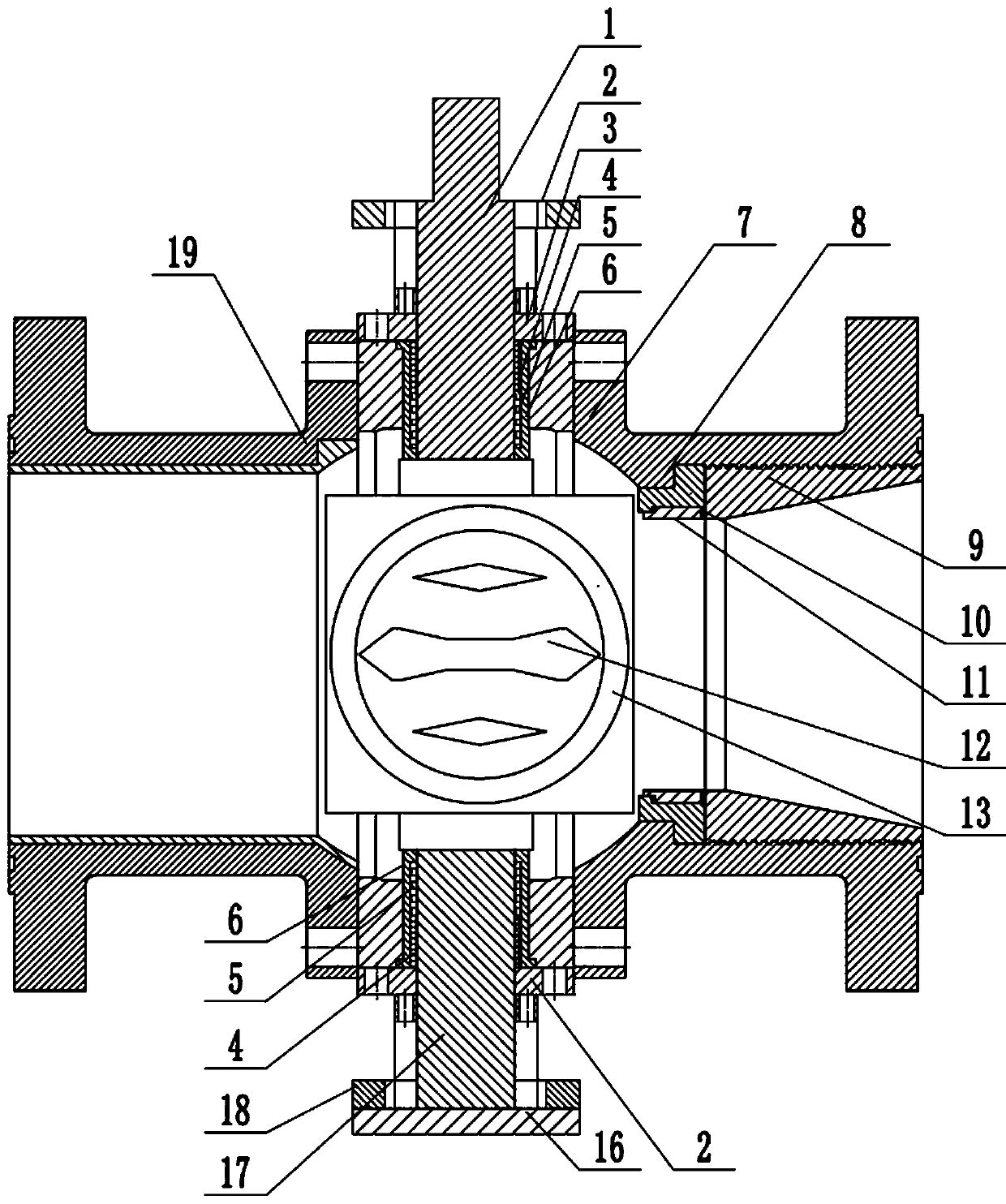

[0037] An erosion-resistant slurry valve, comprising an upper valve shaft 1, a large gland 6, a valve body 7, a valve plate 13 and a lower valve shaft 17, and the side of the valve body 7 is provided with an inlet and an outlet; The top surface and the bottom surface of the valve body 7 are respectively provided with mounting holes for the large gland 6, the large gland 6 is installed in the mounting hole, the valve plate 13 is supported and fixed in the valve body 7 by the large gland 6, and the upper The valve shaft 1 and the lower valve shaft 17 respectively pass through the large gland 6 installed on the top surface and the bottom surface of the valve body 7 and then connect with the valve plate 13. The coupling hole of the valve shaft is not subject to any impact, and is firm and reliable; packing 5 and bearing sleeve 4 are installed between the large gland 6 and the valve shaft, and the packing gland 3 presses the packing 5 and the bearing sleeve 4 supporting the rotation...

Embodiment 2

[0041] An erosion-resistant slurry valve, comprising an upper valve shaft 1, a large gland 6, a valve body 7, a valve plate 13 and a lower valve shaft 17, and the side of the valve body 7 is provided with an inlet and an outlet; The top surface and the bottom surface of the valve body 7 are respectively provided with mounting holes for the large gland 6, the large gland 6 is installed in the mounting hole, the valve plate 13 is supported and fixed in the valve body 7 by the large gland 6, and the upper The valve shaft 1 and the lower valve shaft 17 respectively pass through the large gland 6 installed on the top surface and the bottom surface of the valve body 7 and then connect with the valve plate 13. The coupling hole of the valve shaft is not subject to any impact, and is firm and reliable; packing 5 and bearing sleeve 4 are installed between the large gland 6 and the valve shaft, and the packing gland 3 presses the packing 5 and the bearing sleeve 4 supporting the rotation...

Embodiment 3

[0047] An erosion-resistant slurry valve, comprising an upper valve shaft 1, a large gland 6, a valve body 7, a valve plate 13 and a lower valve shaft 17, and the side of the valve body 7 is provided with an inlet and an outlet; The top surface and the bottom surface of the valve body 7 are respectively provided with mounting holes for the large gland 6, the large gland 6 is installed in the mounting hole, the valve plate 13 is supported and fixed in the valve body 7 by the large gland 6, and the upper The valve shaft 1 and the lower valve shaft 17 respectively pass through the large gland 6 installed on the top surface and the bottom surface of the valve body 7 and then connect with the valve plate 13. The coupling hole of the valve shaft is not subject to any impact, and is firm and reliable; packing 5 and bearing sleeve 4 are installed between the large gland 6 and the valve shaft, and the packing gland 3 presses the packing 5 and the bearing sleeve 4 supporting the rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com