A kind of preparation method of implant body with porosity gradient change

A gradient change, implant technology, applied in the field of biological bone implantation and repair, can solve problems such as inability to match mechanical performance requirements, stress shielding, etc., and achieve the effect of facilitating transmission and proliferation, increasing stiffness, and high simulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

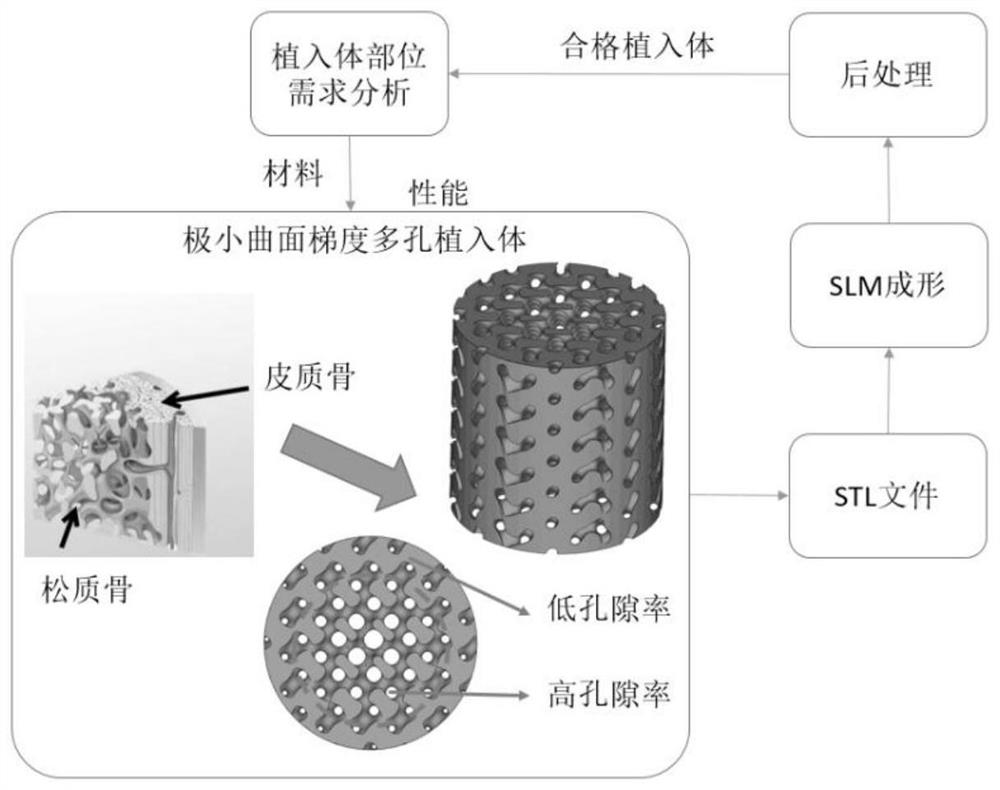

[0025] A method for preparing an implant with a gradient porosity change. According to the requirements of the implant site, a gradient porous structure is customized; a three-dimensional model of a continuous gradient porous structure based on a minimal curved surface is constructed through mathematical modeling, and then the model is Output in STL format; import the STL file into the additive manufacturing forming equipment, and finally obtain a gradient porous structure consistent with the design model through layer-by-layer accumulation; finally, a gradient porous implant with good performance can be obtained after proper post-processing. For biological tissue repair.

[0026] in particular, figure 1 It is a flow chart of the preparation method of the implant with the gradient change of porosity constructed according to the preferred embodiment of the present invention, such as figure 1 As shown, the method includes the following steps:

[0027] (1) According to differen...

Embodiment 1

[0042] (1) According to the damaged part of the patient is cortical bone, the porosity of the porous structure is required to be 10%-20%, and the Young's modulus is about 30-20GPa, so it matches the Swartz Primitive structure and Ti-24Nb-4Zr-8Sn material, the porosity Grading from 15% to 20%, the Young's modulus is predicted to be 35.0-22.9 GPa.

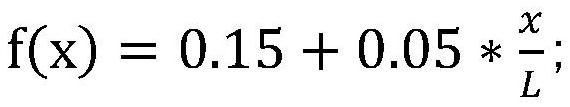

[0043] (2) First confirm that the porosity change equation along the X direction is:

[0044] f(x=0)=0.15;

[0045]

[0046] Among them, x is the space coordinate, L is the total length of the porous structure in the X direction, and the Swartz Primitive implicit function equation is combined to generate the Swartz Primitive minimal surface gradient porous structure.

[0047] Use the algorithm to distinguish the inside and outside of the surface, and close the inner boundary of the surface to form a rod-shaped solid model with a minimal curved surface; or give the surface a thickness to form a thin-walled solid model with a minim...

Embodiment 2

[0052] (1) According to the damaged part of the patient is cancellous bone, the porosity of the porous structure is required to be 50%-90%, and the Young's modulus is about 5.0-3.0GPa, so it matches the Schoen Gyroid structure and Ti-6Al-4V material, the porosity Grading from 70% to 75%, the Young's modulus is predicted to be 5.5-3.3 GPa.

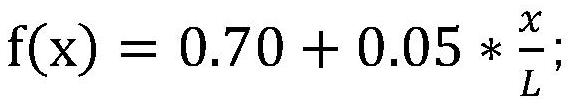

[0053] (2) First confirm that the equation of porosity changing with space is:

[0054] f(x=0)=0.70;

[0055]

[0056] Among them, x is the space coordinate, L is the total length of the porous structure in the X direction, and the Gyroid implicit function equation is combined to generate the Gyroid minimal surface gradient porous structure.

[0057] Use the algorithm to distinguish the inside and outside of the surface, and close the inner boundary of the surface to form a rod-shaped solid model with a minimal curved surface; or give the surface a thickness to form a thin-walled solid model with a minimal curved surface;

[0058] (3) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com